Composite material J type longitudinal wall positioning integral forming tool and forming method thereof

A technology for forming tooling and composite materials, which is applied in the field of integrally formed positioning tooling, which can solve the problems of vacuum bag breakdown, difficult packaging, and affecting assembly quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

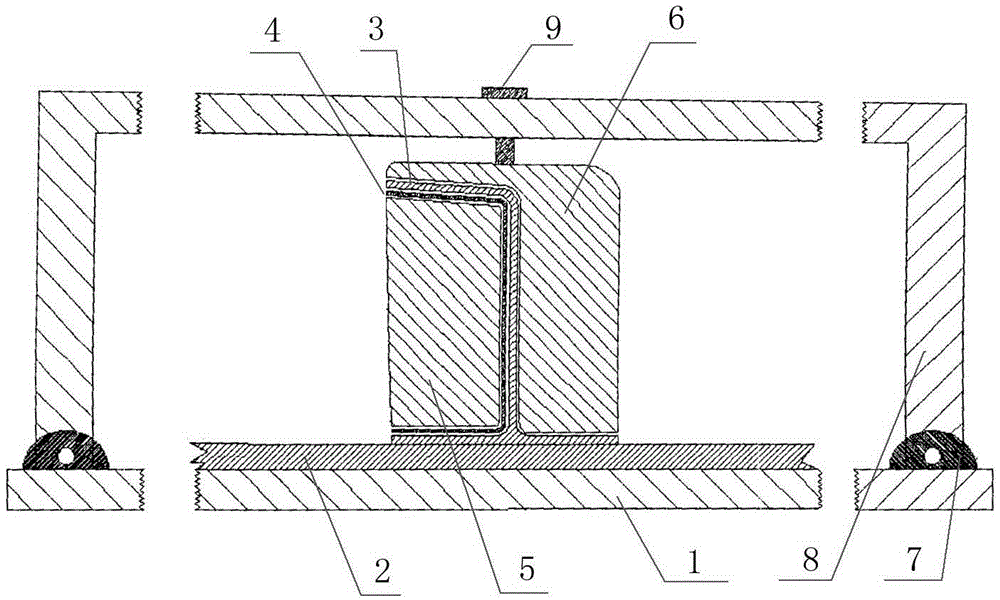

[0015] Such as figure 1 As shown, a composite material J-shaped vertical wall positioning overall forming tooling is provided with a basic skin 2 on the skin forming tooling 1, and a J-shaped vertical wall 3 is set at a designated position on the upper surface of the basic skin 2. The inner surface of the vertical wall 3 is provided with the internal tooling 5 for forming the vertical wall through the rubber compensation layer 4, and the thickness of the rubber compensation layer 4 is 2 to 4 mm, which is used to apply pressure evenly to the J-shaped longitudinal wall to ensure the internal quality of the J-shaped longitudinal wall, and The inner shape of the vertical wall molding 5 completely fills the inner shape of the J-shaped vertical wall 3, and the outer surface of the J-shaped vertical wall 3 is covered with the outer surface of the vertical wall molding 6, the outer molding tool of the vertical wall 6, the inner tooling 5 of the vertical wall and the J The longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com