Electric clamp capable of rapidly changing clamping surface

A clamping surface, electric technology, applied in the direction of workpiece clamping device, clamping, manufacturing tools, etc., can solve the problem of single fixture difficult to plane, curved surface clamping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

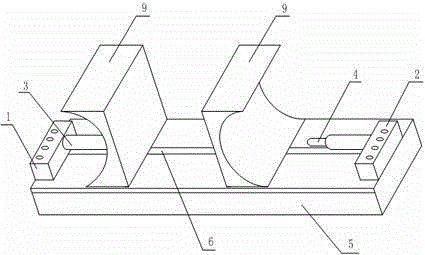

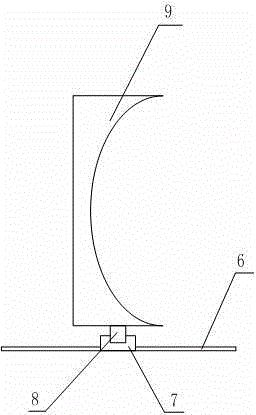

[0017] Such as figure 1 versus figure 2 The illustrated electric clamp for quickly changing the clamping surface includes a base 5, and the left and right ends of the upper surface of the base 5 are respectively provided with a first driving motor 1 and a second driving motor 2, the first driving The output ends of the motor 1 and the second drive motor 2 are respectively connected with a first electric push rod 3 and a second electric push rod 4. The upper surface of the base 5 is also provided with a sliding groove 6 which is provided with two There are two sliders 7, each slider 7 is provided with a vertical rotating shaft 8, each rotating shaft 8 is fixedly connected with a clamping plate 9, each clamping plate 9 is a flat surface, the other side It is a curved surface; wherein the sliding groove 6 is provided in the middle of the upper surface of the base 5, and the width of the clamping plate 9 is consistent with the width of the base 5. In this embodiment, two clamping ...

Embodiment 2

[0019] Such as image 3 In the illustrated electric clamp for quickly changing the clamping surface, on the basis of Embodiment 1, the side surface of the base 5, the side surface and the top surface of the clamping plate 9 are all provided with size scale bars 10. The size scale bar 10 is used to determine the width and height of the workpiece to be processed, which facilitates the measurement of the workpiece and improves the processing accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com