A kind of high-efficiency indexable compound reaming drill and its processing method and using method

A reaming drilling and indexing technology, which is applied in the direction of boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of large force changes on the tool, easy shaking of the tool, and low processing efficiency. Achieve the effects of reducing processing difficulty, improving operability, and reducing the number of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

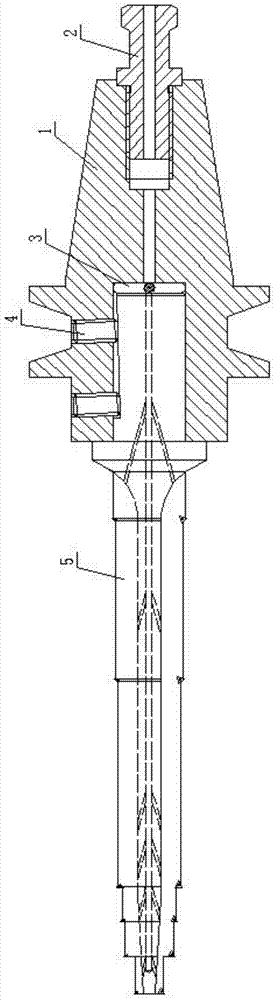

[0044] The present invention comprises design-processing and use three steps, specifically:

[0045] 1. Design high-efficiency indexable composite reaming drill

[0046] 1. The pull stud 2 selects standard parts with internal cooling holes according to the specific numerical control equipment.

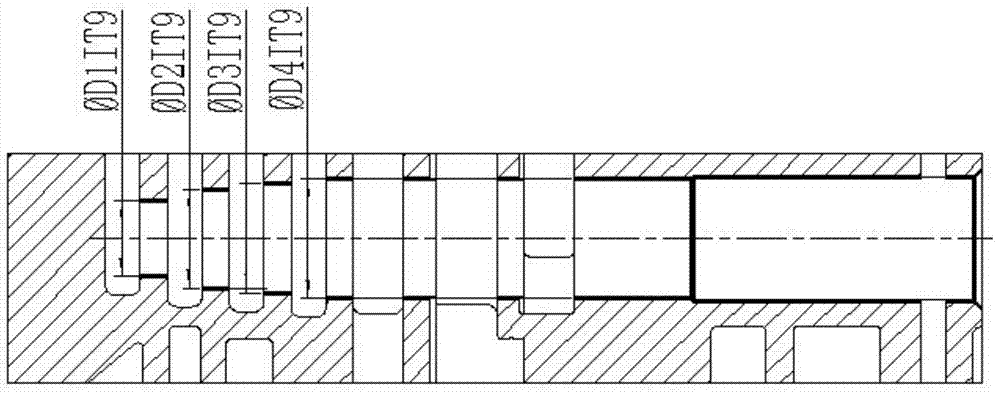

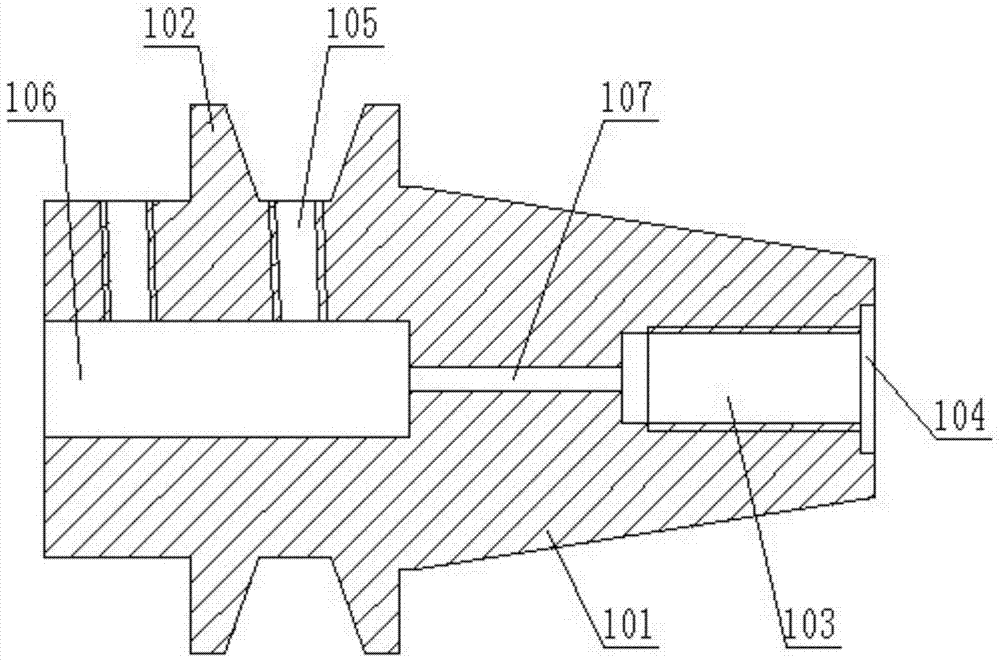

[0047]2. The tool handle assembly 1 is a side-fixed tool handle, the overall hardness is HRC28-32, and the material is made of 2Cr13. The inner thread of the center screw hole 104 of the tool handle assembly 1 and the counterbore 104 are designed according to the outer thread and outer circle of the pull stud 2 respectively, the precision of the inner thread is grade 5, and the fit clearance between the counterbore 104 and the outer circle of the pull stud 2 Guarantee ≤0.01mm. The outer taper of the tool handle seat 101 and the flange 102 are designed according to the interface size of the machine tool spindle, wherein the outer taper of the tool handle seat 101 is ground to ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com