NCVM (Non Conductive Vacuum Metallization) spraying surface treatment process and NCVM product

A surface treatment and process technology, applied in the field of NCVM, can solve the problem that the shell can not meet the needs of consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

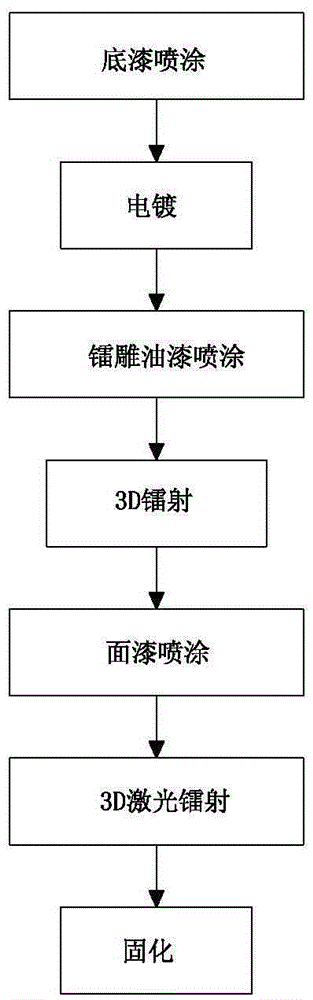

Method used

Image

Examples

Embodiment Construction

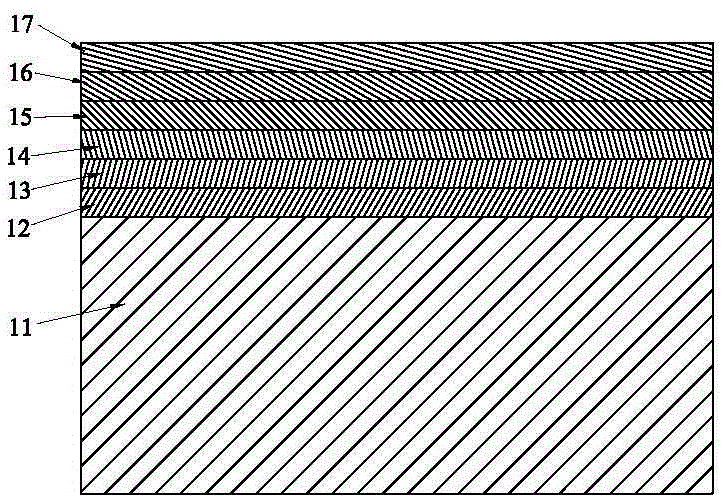

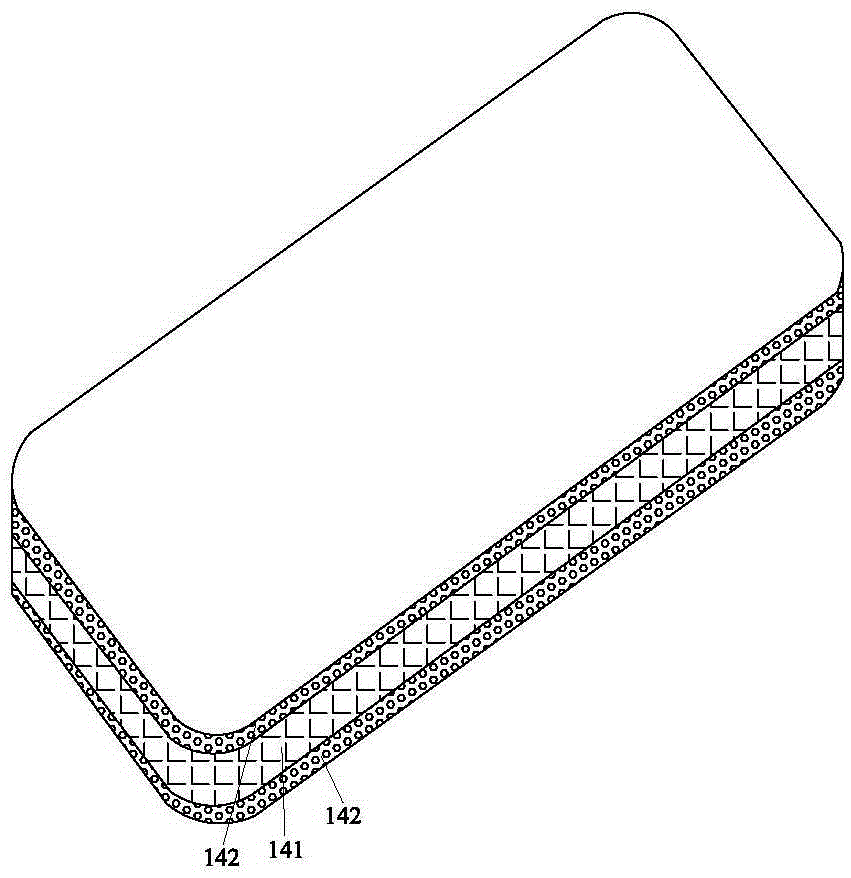

[0031] Please refer to figure 2 with image 3 Shown, it has shown the concrete structure of preferred embodiment NCVM product of the present invention, comprises base material 11, primer layer 12, coating film layer 13, laser carving paint layer 14, laser carving layer 15, finish paint layer 16 And the laser layer 17, the substrate 11, the primer layer 12, the coating layer 13, the laser engraving paint layer 14, the laser engraving layer 15, the top coat layer 16 and the laser layer 17 are sequentially stacked together from bottom to top. The base material 11 is a mobile phone plastic shell, and the radium engraving paint layer 14 has a radium engraving area 141 and a non-radium engraving area 142. The radium engraving area 141 is located on the side of the mobile phone plastic shell, and the center line of the radium engraving area 141 is aligned with the plastic shell. The center lines of the sides coincide, and the non-laser engraving area 142 is located on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com