Table type gas single cylinder fryer

A gas-fired, single-cylinder technology, which is applied in the direction of special commodity baking, baking, oil/fat baking, etc., can solve the problems of low thermal efficiency utilization, high gas consumption, etc., and achieve the effect of beautiful appearance and reduced space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the description.

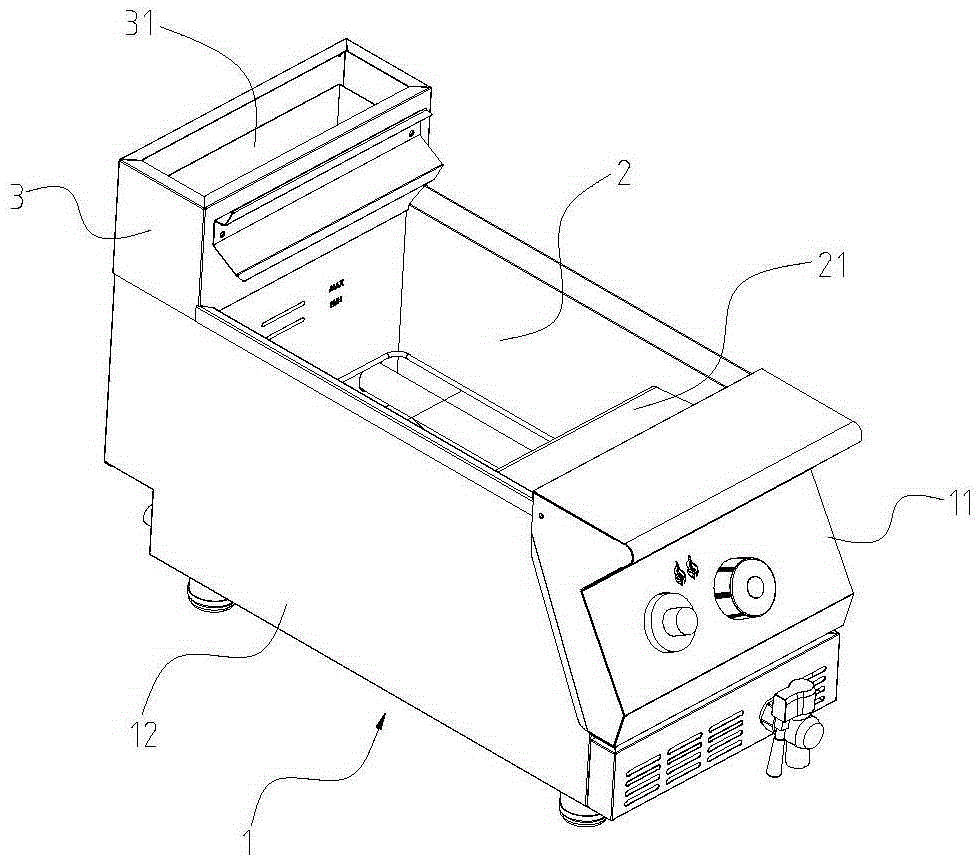

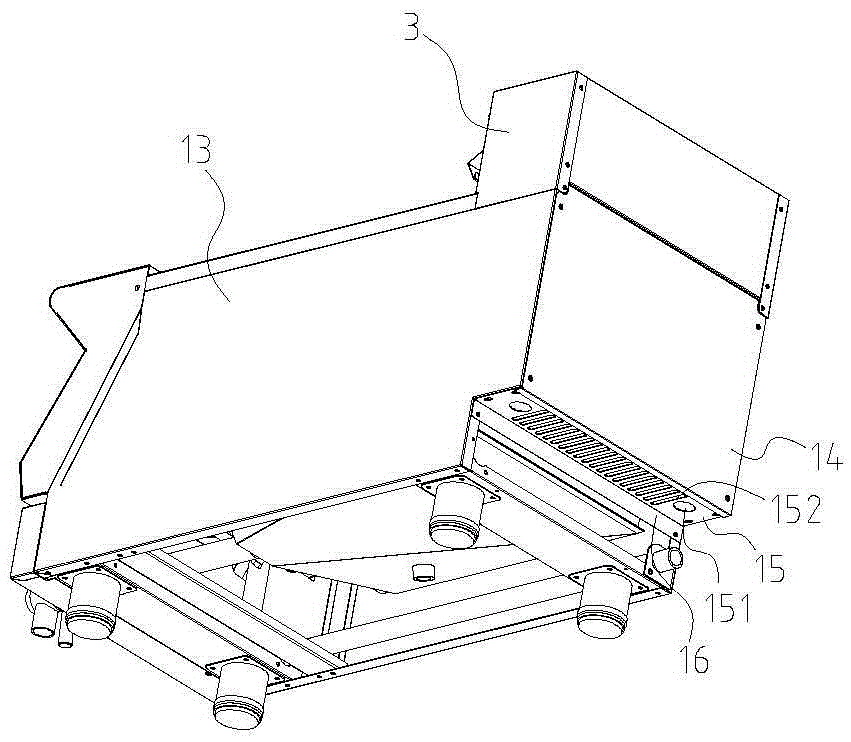

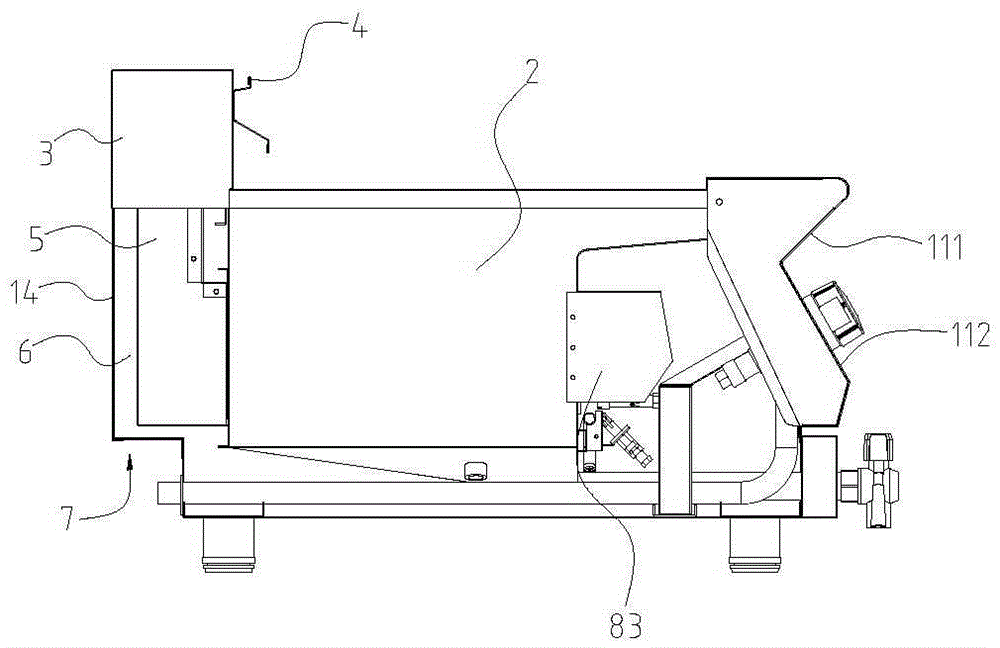

[0026] Such as figure 1 As shown, a desktop gas single-cylinder fryer includes a housing 1, an oil tank 2, a heating assembly and a control system.

[0027] Such as Figures 1 to 3 As shown, the housing 1 includes a front sealing plate 11, a rear sealing plate, a left side plate 12 and a right side plate 13, and the front sealing plate 11, the rear sealing plate, the left side plate 12 and the right side plate 13 of the housing 1 An accommodating cavity is enclosed, and the oil tank 2 is installed in the accommodating cavity of the housing 1 . The front cover 11 includes a shielding plate 111 and a control panel 112 , the angle between the shielding plate 111 and the control panel 112 is an obtuse angle, and the control panel 112 is provided with control buttons. The baffle plate 111 can shield the oil in the oil tank 2 from splashing to the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com