Energy saver control system for three-phase asynchronous motor

A three-phase asynchronous, control system technology, applied in control systems, AC motor control, electrical components, etc., can solve the problems of increased power loss of motors, increased product costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

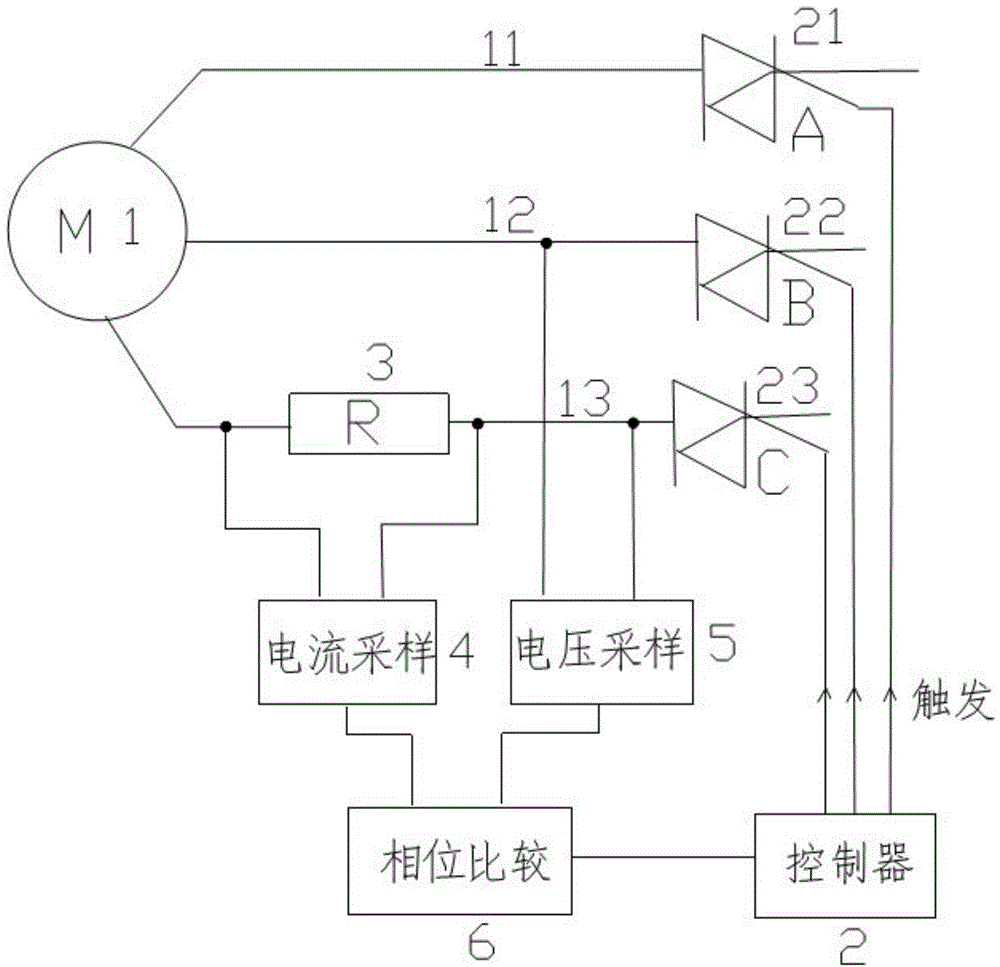

[0010] Such as figure 1 As shown, a three-phase asynchronous motor economizer control system in this embodiment includes a three-phase asynchronous motor 1, a controller 2, a current sampling module 4, a voltage sampling module 5 and a phase comparison module 6. The three-phase asynchronous The motor 1 includes A-phase lead wires 11, B-phase lead wires 12 and C-phase lead wires 13. The A-phase lead wires 11, B-phase lead wires 12 and C-phase lead wires 13 are respectively connected with a thyristor A21 and a thyristor B22. and thyristor C23, the C-phase lead 13 is provided with a resistor 3, the current sampling module 4 is connected to the resistor 3 through a wire, and the voltage sampling module 5 is respectively connected to the B-phase lead 12 and the C-phase through a wire Lead 13, the current sampling module 4 and the voltage sampling module 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com