Tool and method for realizing charged replacement of tension insulator of extra-high voltage earth electrode line

A technology of strain insulators and live replacement, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems that workers cannot be protected from high temperature and high voltage damage, and the operation is cumbersome, so as to avoid long-term contact with high-temperature wires and protect personal safety. Safe, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

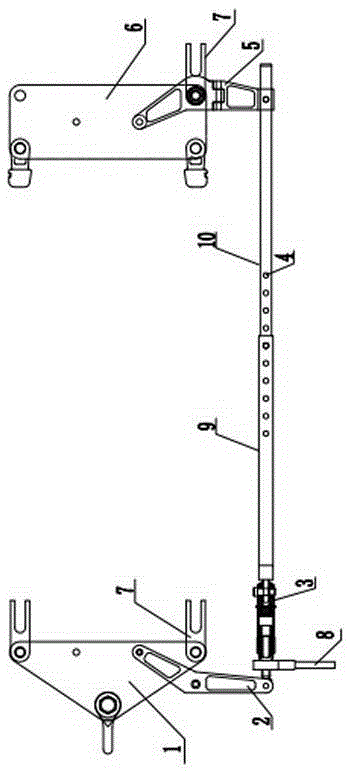

[0035] Such as figure 1 As shown, the tool of the present invention includes a front clamping part 2 , a lead screw 3 , an insulating puller and a rear clamping part 5 . The front clamping part 2 adopts a bent plate clamp, and the front clamping part 2 and one end of the lead screw 3 are fastened and connected by bolts; the insulating pull plate includes a fixing plate 9 and an adjusting plate 10, the fixing plate 9 adopts a hollow structure, and the size of the adjusting plate 10 is smaller than The fixed plate 9 and the adjustable plate 10 can be operated in and out of the fixed plate 9, and the adjustable plate 10 and the fixed plate 9 are uniformly provided with adjustment holes 4; the other end of the lead screw 3 and one end of the fixed plate 9 in the insulating pull One end of the adjustment plate 10 in the insulating pull plate is connected to the rear clamping portion 5 by bolts.

[0036]When in use, the front clamping part 2 is fixedly connected to the triangular c...

Embodiment 2

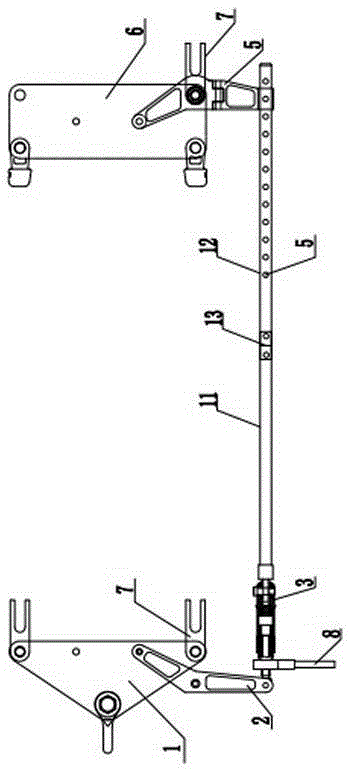

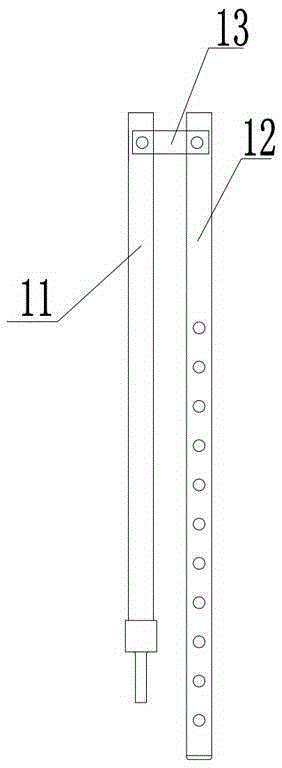

[0038] Such as figure 2 As shown, the tool of the present invention includes a front clamping part 2 , a lead screw 3 , an insulating puller and a rear clamping part 5 . The front clamp part 2 adopts a bent plate clamp, and the front clamp part 2 and one end of the lead screw 3 are fastened and connected by bolts; the insulating pull plate includes a first insulating pull plate 11, a second insulating pull plate 12 and a connecting part 13, and the first insulating pull plate 12 The pull plate 11 and the second insulating pull plate 12 are all installed on the connecting portion 13 through the rotating shaft, and the structure of the insulating pull plate when the insulating pull plate is unfolded is as follows: figure 2 As shown, the folded structure of the insulating pull plate is as follows image 3 As shown, one end of the second insulating pull plate 12 is uniformly provided with an adjustment hole 4; the other end of the lead screw 3 is fastened to the first insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com