Baking oven temperature and humidity control system and method based on two-dimensional space 3-D fuzzy control

A humidity control system, temperature and humidity control technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of not achieving the overall uniform control of the space, poor design, and poor space control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

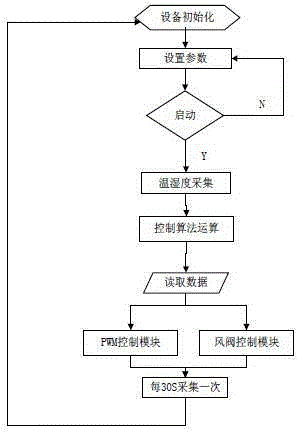

[0026] Embodiment 1: see Figure 1~Figure 4 , the oven temperature and humidity control system based on the two-dimensional space 3-D fuzzy control method, including an oven (1) and a temperature and humidity control system, the oven is equipped with a number of oven temperature and humidity sensors (7 ), there is an air duct (3) in the baking oven (1), and there is a circulating fan (5) and an electric furnace (6) on the air duct (3), and there is a damper device (4) to control the air duct (3). It is characterized in that: the temperature and humidity control system includes a PC (8) and a control signal drive circuit (10), the control signal drive circuit (10) is connected to the PC (8) and the power supply (9), and connected to The damper device (4), circulation fan (5) and electric furnace (6) of the oven (1), and the oven temperature and humidity sensor (7) in the oven (1) is connected to the PC (8) data acquisition module.

Embodiment 2

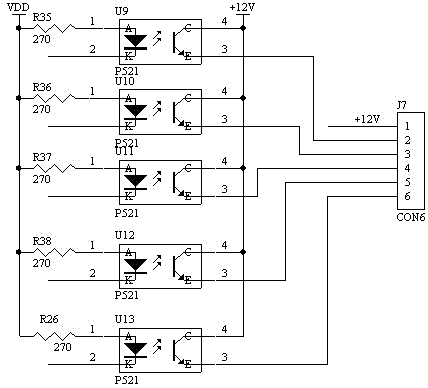

[0027] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: the circuit structure of the control signal drive circuit (10): the control signal amplifier circuit (10-1) in the control signal drive circuit (10) Connect the I / O drive circuit (10-2), the control signal amplification circuit (10-1) is connected with the PC (8) for the control signal amplification and transmission to the drive circuit, the I / O drive circuit (10-2) Connect the control object electric furnace (6), circulation fan (5) and damper device (4), for receiving the control signal to control the driving switch of the corresponding control object. In the control signal drive circuit (10), the voltage at the I / O terminal is very small, and is amplified by a photoelectric coupling signal amplifier circuit, and the amplified signal is transmitted to the I / O drive circuit to drive the solid-state relay, which is controlled by the solid-state relay The switch ...

Embodiment 3

[0028] Embodiment 3: see Figure 5~Figure 9 , the oven temperature and humidity control method based on two-dimensional space 3-D fuzzy control, using the above system to operate, is characterized in that the specific operation steps are as follows:

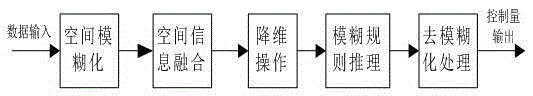

[0029]1) Two-dimensional space 3-D fuzzy controller design: Similar to the traditional fuzzy controller structure, the two-dimensional space 3-D fuzzy controller consists of three parts: space fuzzification, 3-D fuzzy rule reasoning and defuzzification. The specific steps of the two-dimensional space 3-D fuzzy controller are as follows: first, collect data from the space area, that is, the temperature and humidity sensors are arranged in a two-dimensional plane in the oven, so the collected temperature and humidity data reflect the The information on the spatial plane is different from the previous one-dimensional linear distribution. It is converted into a fuzzy input that can represent spatial information through the spatial fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com