Supervision-based industrial process fault detection method of linear dynamic system model

A technology of dynamic system model and industrial process, applied in general control system, control/regulation system, program control, etc., can solve the problems of ignoring important information of quality variable process and utilizing quality variable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

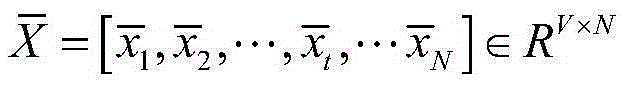

[0051] The invention discloses an industrial process fault detection method based on a supervised linear dynamic system model. The method aims at the fault detection problem of the industrial process. Firstly, a distributed control system is used to collect process variable data and quality variable data, and standardize them deal with. Then a supervised linear dynamic system model is established, and the model parameters are stored in the database for future use. Finally build T for the new online data 2 Statistics, compared with statistical limits to obtain fault detection results.

[0052] The main steps of the technical solution adopted in the present invention are as follows:

[0053] The first step: use the collection and distribution system to collect data of process variables to form a training sample set of process var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com