Temperature control method of hydrogen catalysis combustor

A temperature control method and catalytic burner technology, which are applied to combustion methods, gas fuel burners, burners, etc., can solve the problems of reactor temperature fluctuation, inability to start catalytic combustion reaction, system instability, etc., and achieve low cost, The effect of wide application and simple control technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A temperature control method for a hydrogen catalytic burner, characterized in that: the temperature control method for a hydrogen catalytic burner comprises:

[0024] 1) The data processor collects the outlet temperature of the hydrogen catalytic burner through a temperature sensor;

[0025] 2) The data processor records the temperature change of the hydrogen catalytic burner and compares it with the set value;

[0026] 3) According to the comparison result between the temperature of the catalytic burner and the set value, the data processor feeds back and adjusts the fuel-air ratio of hydrogen and air;

Embodiment 2

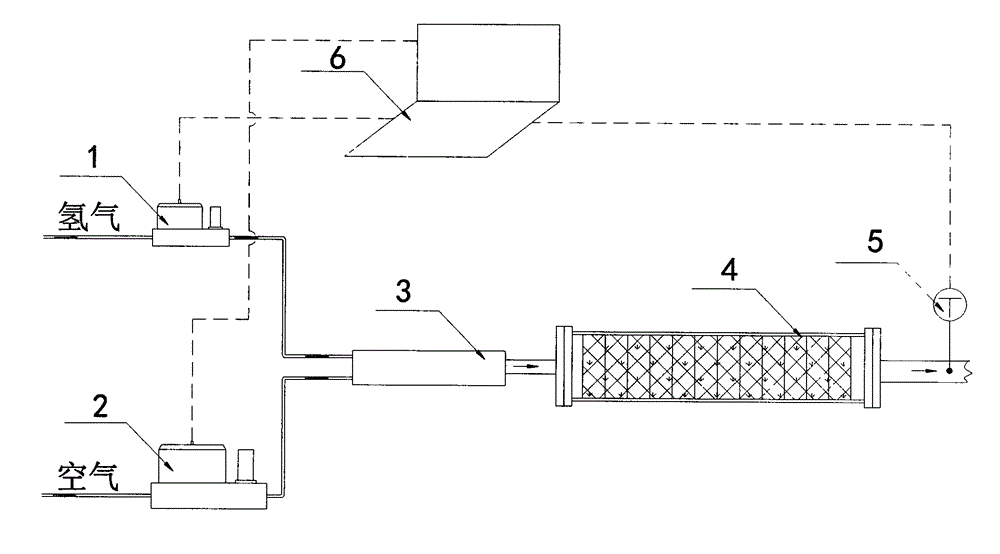

[0028] Set the temperature of the catalytic burner to 280°C (control target), when hydrogen and air with a fuel-to-air ratio of 8% enter the gas mixer 3 through the hydrogen flow controller 1 and the air flow controller 2 respectively, and then pass into the hydrogen catalytic combustion 4, the temperature sensor 5 detects a rapid rise in temperature. When the temperature rises to 280°C, the temperature sensor 5 detects that the temperature continues to rise, and the data processor 6 feeds back signals to the hydrogen flow controller 1 and the air flow controller 2 after comparison and calculation to adjust the fuel-air ratio to 6%. The sensor 5 detects that the temperature drops slowly; when the temperature drops to 260°C, the data processor 6 feeds back signals to the hydrogen flow controller 1 and the air flow controller 2 after comparison and calculation, and adjusts the fuel-air ratio to 7.2%, and finally catalyzes the combustion The temperature of the device was basicall...

Embodiment 3

[0030] Set the temperature of the catalytic burner to 350°C (control target), when hydrogen and air with a fuel-to-air ratio of 11% enter the gas mixer 3 through the hydrogen flow controller 1 and the air flow controller 2 respectively, and then pass into the hydrogen catalytic combustion 4, the temperature sensor 5 detects a rapid rise in temperature. When the temperature rises to 350°C, the temperature sensor 5 detects that the temperature continues to rise, and the data processor 6 feeds back signals to the hydrogen flow controller 1 and the air flow controller 2 after comparison and calculation to adjust the fuel-air ratio to 10%. The sensor 5 detects that the temperature drops slowly; when the temperature drops to 330°C, the data processor 6 feeds back the signal to the hydrogen flow controller 1 and the air flow controller 2 after comparison and calculation, adjusts the fuel-air ratio to 10.5%, and finally catalyzes the combustion The temperature of the device was basica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com