Epoxy resin cable material and preparing method and application thereof

An epoxy resin and cable technology, applied in the direction of insulating cables, plastic/resin/wax insulators, cables, etc., can solve the problems of loss of life and property, obstruction of safe evacuation and fire extinguishing work, etc., to achieve soft insulation and reasonable composition of raw material formula , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

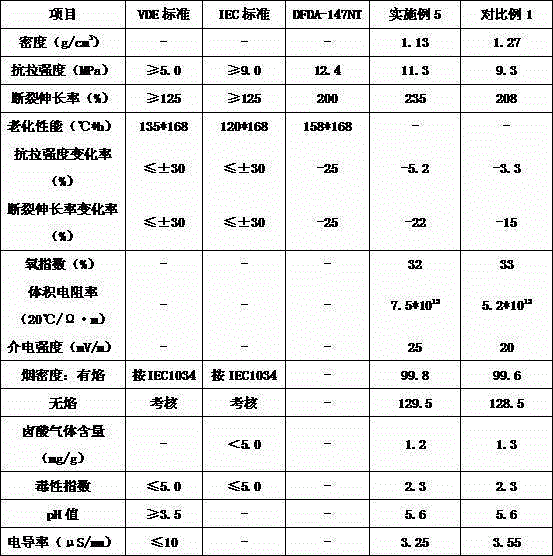

Examples

Embodiment 1

[0018] In the embodiment of the present invention, an epoxy resin cable material is composed of the following raw materials in parts by weight: 68 parts of epoxy resin, 33 parts of Wulingzhi, 10 parts of bentonite, 5 parts of titanate coupling agent, polypropylene 43 parts of resin, 10 parts of talcum powder, 3 parts of sodium bifluoride.

[0019] Add 15 times the mass of Wulingzhi to Wulingzhi with ethanol with a mass concentration of 90%, heat and reflux for extraction, let cool to room temperature, filter, collect the ethanol extract, and concentrate to 11% of the original volume; spray-dried to obtain Wulingzhi extract. Put the epoxy resin into 90% ethanol which is 13 times its mass, raise the temperature to 66°C at a speed of 100r / min, then add talcum powder and stir for 8min, then cool down to 45°C, then add sodium bifluoride and Bentonite, after stirring for 1 h, mixture A was prepared. Add polypropylene resin and titanate coupling agent to mixture A, raise the temper...

Embodiment 2

[0021] In the embodiment of the present invention, an epoxy resin cable material is composed of the following raw materials in parts by weight: 75 parts of epoxy resin, 39 parts of Wulingzhi, 16 parts of bentonite, 10 parts of titanate coupling agent, polypropylene 48 parts of resin, 16 parts of talcum powder, 8 parts of sodium bifluoride.

[0022] Add 95% ethanol with a mass concentration of 16 times the mass of Wulingzhi to Wulingzhi, heat and reflux for extraction, let cool to room temperature, filter, collect the ethanol extract, and concentrate to 13% of the original volume; spray-dried to obtain Wulingzhi extract. Put the epoxy resin into ethanol with a mass concentration of 95% that is 15 times its mass, raise the temperature to 68°C at a speed of 150r / min, then add talcum powder and stir for 10 minutes, then cool down to 48°C, then add sodium bifluoride and Bentonite, after stirring for 1.5h, mixture A was prepared. Add polypropylene resin and titanate coupling agent...

Embodiment 3

[0024] In the embodiment of the present invention, an epoxy resin cable material is composed of the following raw materials in parts by weight: 70 parts of epoxy resin, 35 parts of Wulingzhi, 12 parts of bentonite, 7 parts of titanate coupling agent, polypropylene 45 parts of resin, 12 parts of talcum powder, 5 parts of sodium bifluoride.

[0025] Add 15.5 times the mass of Wulingzhi to Wulingzhi with ethanol with a mass concentration of 95%, heat and reflux for extraction, let cool to room temperature, filter, collect the ethanol extract, concentrate to 12% of the original volume; spray-dry to obtain Wulingzhi extract. Put the epoxy resin into 14 times its mass of ethanol with a mass concentration of 95%, raise the temperature to 67°C at a speed of 125r / min, then add talcum powder and stir for 9 minutes, then cool down to 46°C, then add sodium bifluoride and Bentonite, after stirring for 1.2h, the mixture A was prepared. Add polypropylene resin and titanate coupling agent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com