Rice dry seedling raising substrate and production method thereof

A dry seedling raising and substrate technology, applied in the agricultural field, can solve problems such as complex process, and achieve the effects of simple process, convenient operation and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

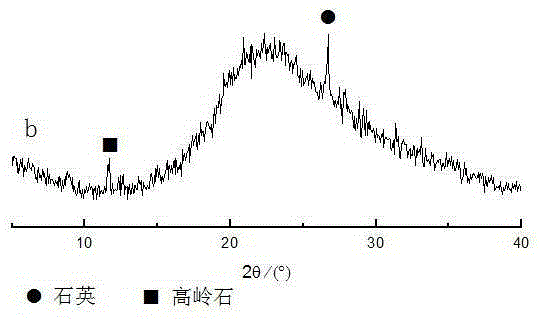

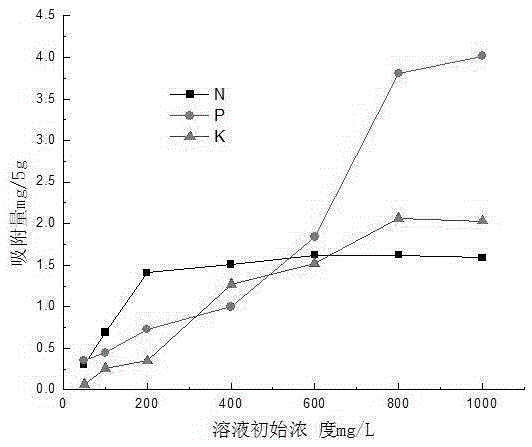

Method used

Image

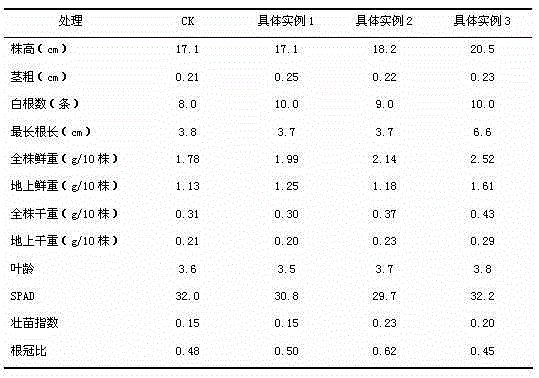

Examples

Embodiment 1

[0039] The weight part that the present invention constitutes formula is:

[0040] Diatomaceous earth tailings 30

[0041] Bentonite 10

[0042] Biochar 3

[0043] Vermiculite 20

[0044] Organic Fertilizer 7

[0045] Fertilizer 0.12.

[0046] Among them, the fertilizer contains 0.2 nitrogen fertilizer, 0.025 phosphorus fertilizer and 0.06 potassium fertilizer.

[0047] (1) Mix diatomite tailings, biochar, bentonite, organic fertilizer, and vermiculite in parts by weight, fully stir and mix evenly to obtain a seedling-raising matrix premix for later use;

[0048] (2) According to the weight of the substrate, take 0.7 ammonium sulfate, 0.06 calcium superphosphate, and 0.01 potassium sulfate, grind them thoroughly, pass them all through a 0.5mm sieve, and evenly sprinkle them into the seedling substrate premix prepared in the above step (1), and mix well Get the substrate for spare;

[0049] (3) Mix concentrated sulfuric acid 2.2-3.4 with water and spray it into the matri...

Embodiment 2

[0051] The weight part that the present invention constitutes formula is:

[0052] Diatomaceous earth tailings 40

[0053] Bentonite 25

[0054] Biochar 12

[0055] Vermiculite 15

[0056] Organic Fertilizer 14

[0057] Fertilizer 0.8.

[0058] Among them, the fertilizer contains 0.25 nitrogen fertilizer, 0.025 phosphorus fertilizer and 0.06 potassium fertilizer.

[0059] The production method of paddy rice dry seedling raising substrate of the present invention, its steps are:

[0060] (1) Mix diatomite tailings, biochar, bentonite, organic fertilizer, and vermiculite in parts by weight, fully stir and mix evenly to obtain a seedling-raising matrix premix for later use;

[0061] (2) According to the weight of the substrate, take 1 ammonium sulfate, 0.09 heavy superphosphate, and 0.6 potassium sulfate, grind them thoroughly, pass them all through a 0.5mm sieve, and evenly sprinkle them into the seedling substrate premix prepared in the above step (1), and mix well Get t...

Embodiment 3

[0064] The weight part that the present invention constitutes formula is:

[0065] Diatomaceous earth tailings 50

[0066] Bentonite 30

[0067] Biochar 20

[0068] Vermiculite 30

[0069] Organic Fertilizer 20

[0070] fertilizer 1.5.

[0071] Among them, the fertilizer contains 0.3 nitrogen fertilizer, 0.025 phosphorus fertilizer and 0.06 potassium fertilizer.

[0072] The production method of paddy rice dry seedling raising substrate of the present invention, its steps are:

[0073] (1) Mix diatomite tailings, biochar, bentonite, organic fertilizer, and vermiculite in parts by weight, fully stir and mix evenly to obtain a seedling-raising matrix premix for later use;

[0074](2) According to the weight of the substrate, take 1.3 ammonium sulfate, 0.12 calcium superphosphate, and 1.2 potassium sulfate, grind them thoroughly, pass them all through a 0.5mm sieve, evenly sprinkle them into the seedling substrate premix prepared in the above step (1), and mix well Get the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com