Rapid bar material clamping and grabbing device

A grasping device and fast technology, applied in the directions of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that people cannot grasp with bare hands and burn their hands, and achieve the effect of high degree of automation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

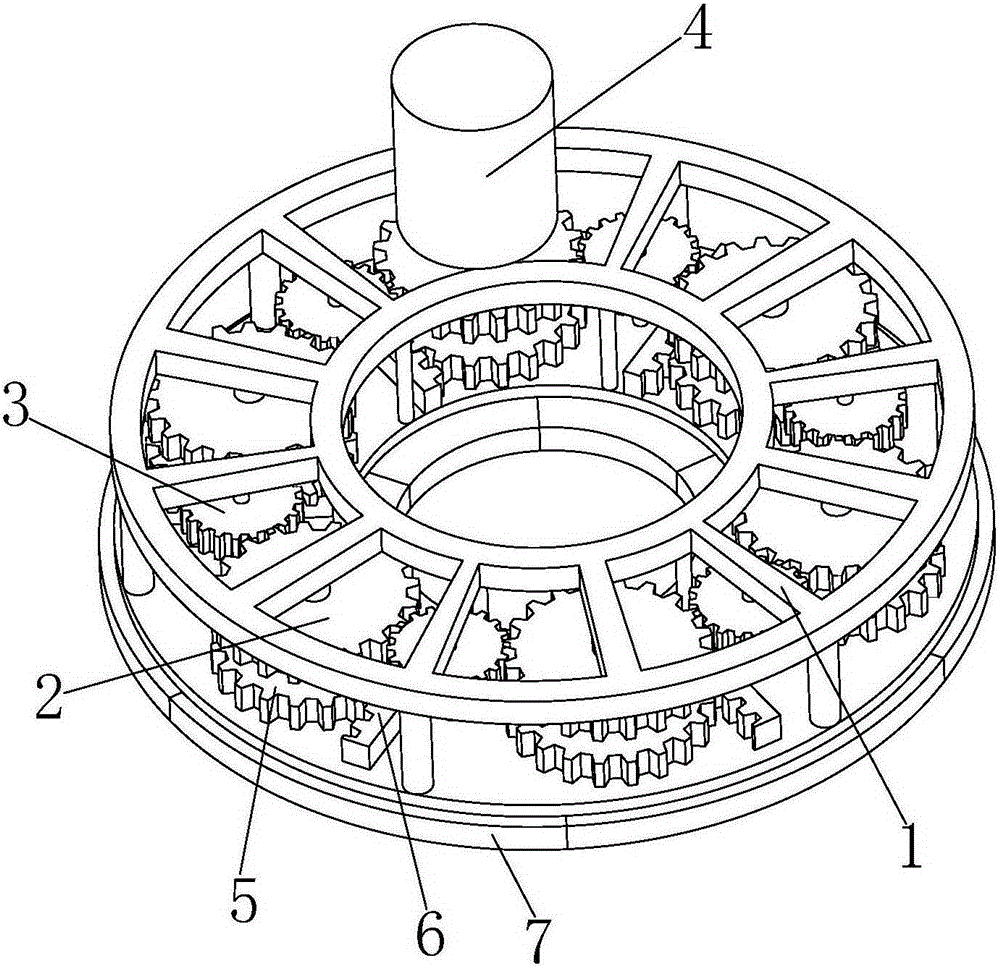

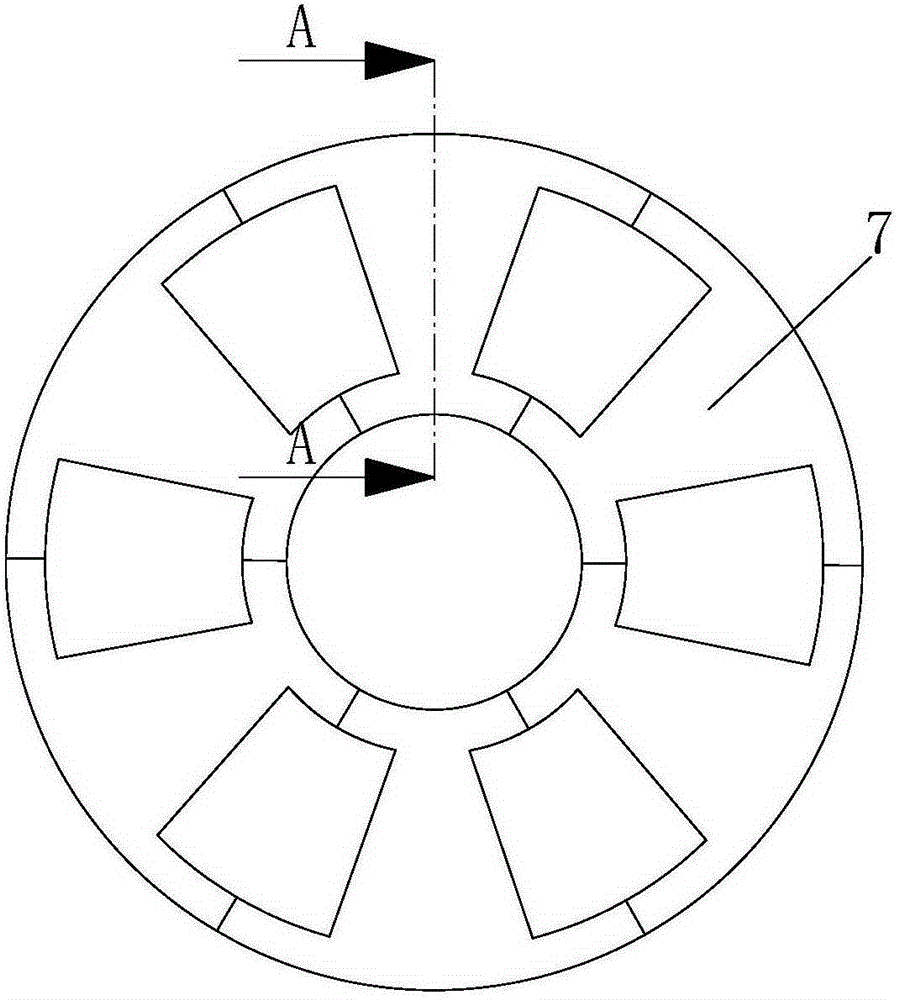

[0017] Such as Figure 1 to Figure 3 As shown, a fast clamping and grabbing device for bar material mainly includes a circular general base body 1, and six transmission gears 2 are evenly installed inside the general base body 1 along the circular direction; the six transmission gears Between every two adjacent transmission gears 2 in 2, there is an idler gear 3 that meshes with the two, and any transmission gear 2 in the six transmission gears 2 is connected with a motor 4 .

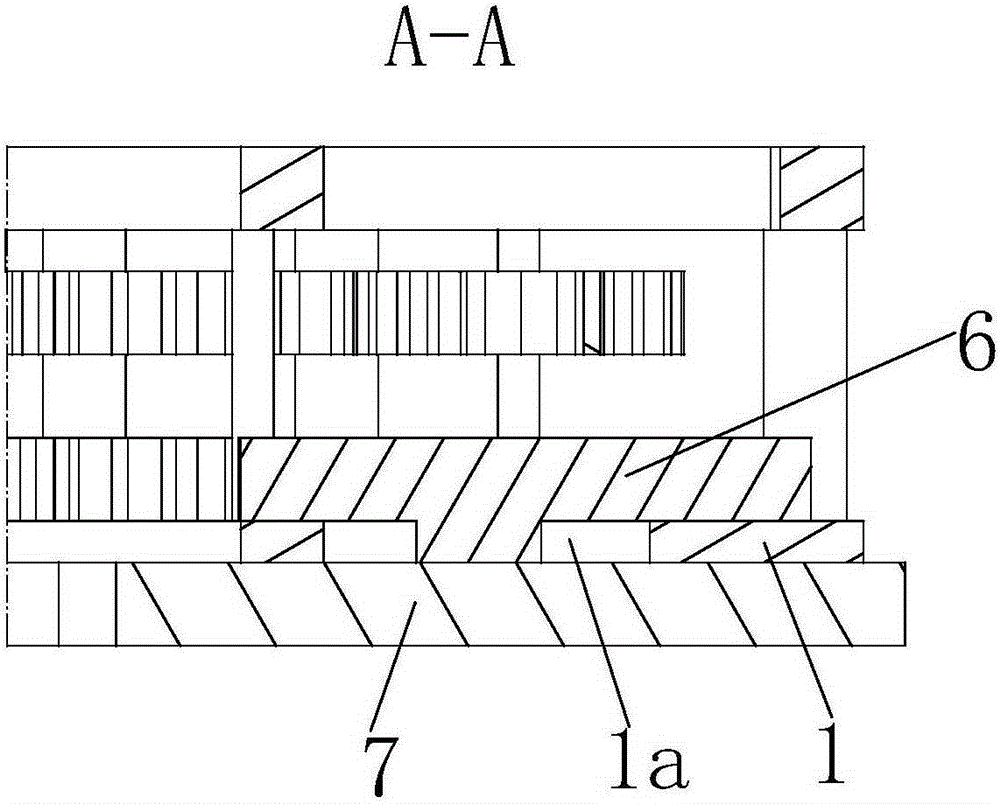

[0018] The lower end of the transmission gear 2 is connected to a transmission gear 5, and the transmission gear 5 is meshed with a rack 6. There are six gears on the main base 1 that are respectively one-to-one corresponding to the sliding installation of the rack 6. The sliding slot 1a, the lower end of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com