Professional mechanical device for grinding guide rail

A technology of professional machinery and guide rails, which is applied in the field of special abrasive mechanical devices, can solve the problems of low grinding precision and high labor intensity of personnel, and achieve the effects of high processing accuracy, reduced labor intensity of workers and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

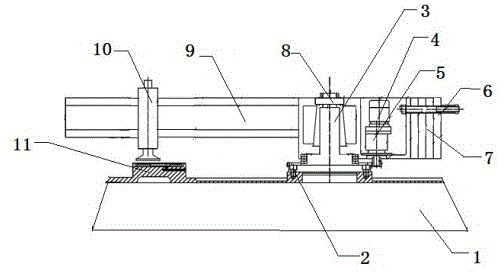

[0012] This embodiment provides a professional mechanical device for grinding guide rails, which is characterized in that: the professional mechanical device for grinding guide rails includes a base (1), fixing bolts (2), a main shaft (3), Motor (4), reducer (5), load-bearing rod (6), counterweight (7), fastening nut (8), beam (9), grinding head (10), guide rail (11);

[0013] Among them: the motor (4) and the reducer (5) are connected and installed on the beam (9), the right end of the beam (9) is welded with a load-bearing rod (6), and the load-bearing rod (6) is used to install the counterweight (7 ), the main shaft (3) is vertically welded with the beam (9), the grinding head (10) is installed on the beam (9), and the guide rail (11) is supported by the base (1).

[0014] The material of the beam (9) is high wear-resistant material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com