Novel mould structure

A new type of mold and mold technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as quality decline and deformation, and achieve the effect of improving quality, prolonging service life, and preventing abnormal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment

[0013] The present invention is described further:

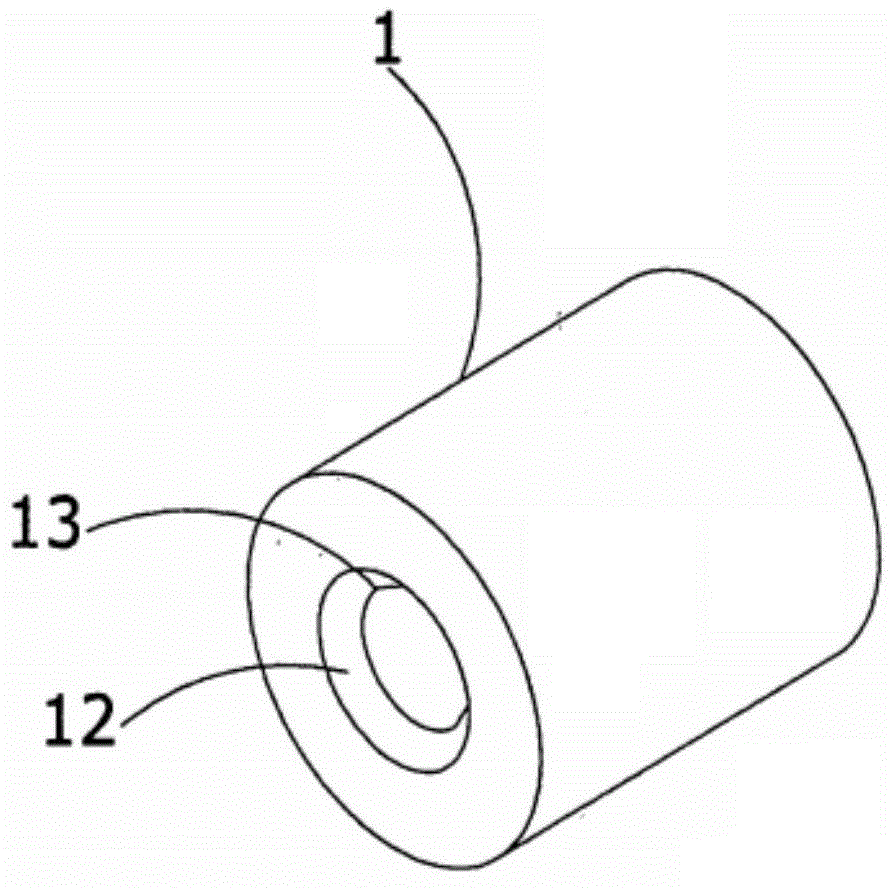

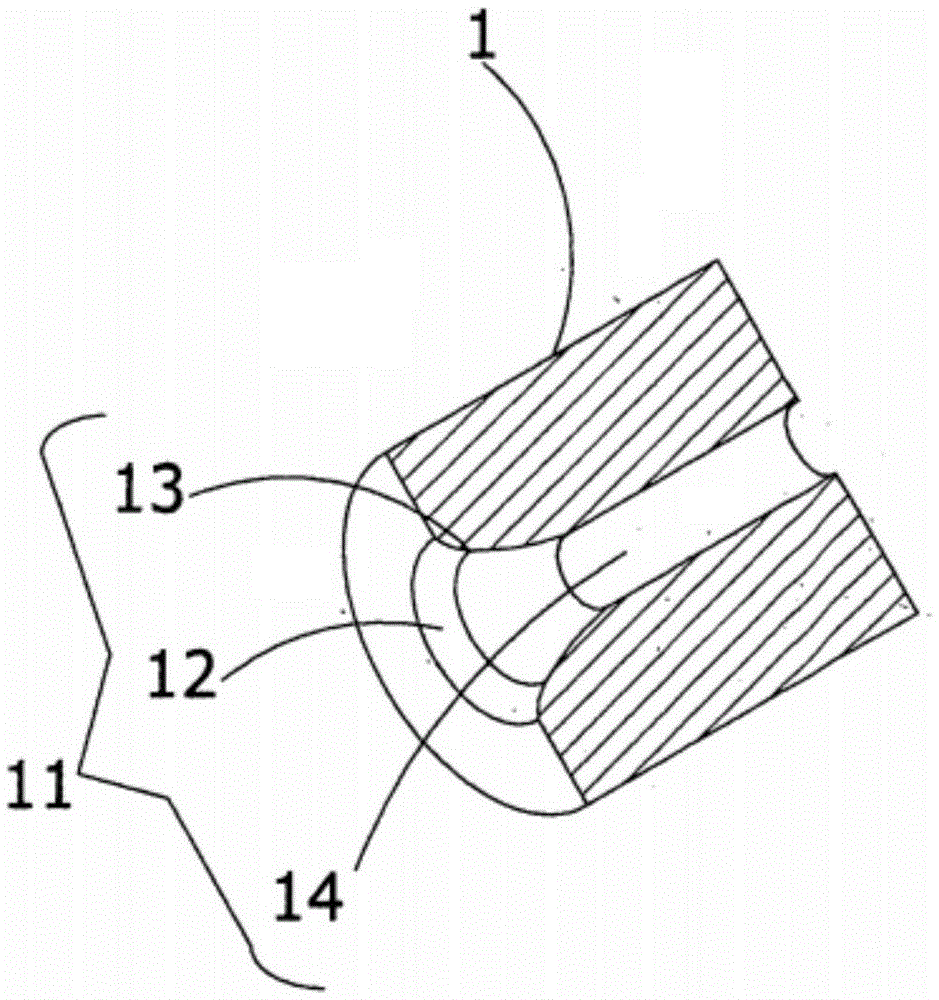

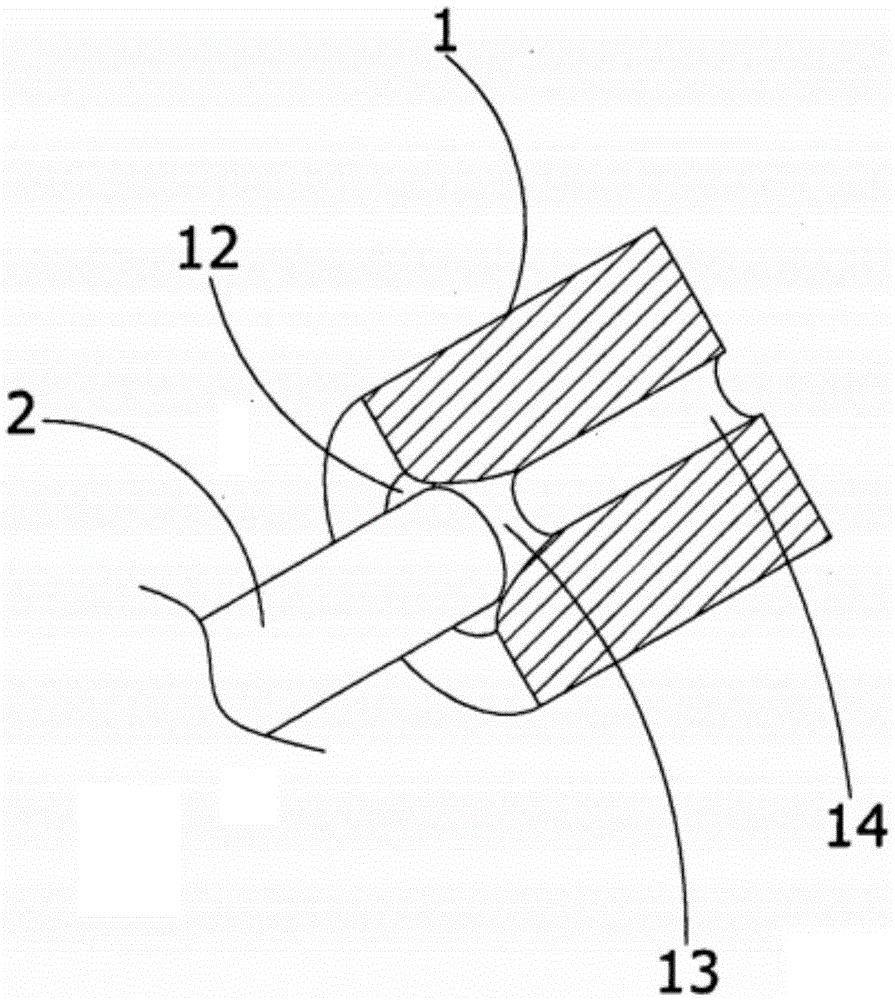

[0014] Such as Figure 1-Figure 3 As shown, a novel mold structure, the mold body 1 is integrally formed. The mold body 1 includes a through-shaped pipe 11 opened along the axis; the pipe 11 includes an opening 12 , a tapered portion 13 and an extension 14 .

[0015] The opening 12 is arranged on the surface of the mold body 1, and the opening 12 extends to one end of the pipeline 11; the diameter of the opening 12 is greater than the outer diameter of the pipe to be installed; the diameter of the opening of the opening 12 is greater than the diameter of the tapered portion 13, The extension 14 extends the end of the pipeline 11 from the other end of the tapered portion 13, and the diameter of the extended portion 14 is the same as the minimum diameter of the tapered portion 13; the minimum radius of the tapered portion 13 is 4cm; the tapered portion 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com