Mouthwash and preparation method thereof

A technology of mouthwash and water phase, which is applied in the field of daily food and chemical products. It can solve the problems that it is not recommended to eat, complex ingredients, and mouthwash is not suitable for children and drivers. It can prevent volatilization, prolong the cool feeling, and prolong the cool feeling time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh WS-23: 0.1 parts by weight, Menthol: 0.1 parts by weight, Polysorbate: 0.1 parts by weight, Glycerin: 10 parts by weight, Sweetener: 100 parts by weight, Preservative: 0.5 parts by weight, Essence: 1 part by weight Parts, purified water: 800 parts by weight;

[0047] Preparation: Grinding menthol at low temperature, the grinding temperature is not higher than 35°C, and pulverizing the menthol until the particle size D90 value is less than 380um; adding the prepared menthol powder, WS-23 and polysorbate into glycerin under the condition of stirring, fully Stir to obtain an oil phase solution;

[0048] Add the sweetener, preservative, and essence into purified water to dissolve and stir to obtain an aqueous phase solution;

[0049]Slowly add the prepared oil phase solution into the stirring water phase solution, control the linear velocity to 0.4-1.0 m / s, and stir at a speed of 600-800 rpm for 30-50 minutes to obtain mouthwash.

Embodiment 2

[0051] Weigh WS-23: 1 part by weight, Menthol: 1 part by weight, Polysorbate: 1 part by weight, Glycerin: 10 parts by weight, Sweetener: 100 parts by weight, Preservative: 0.5 parts by weight, Essence: 1 part by weight Parts, purified water: 800 parts by weight;

[0052] Preparation: Grinding menthol at low temperature, the grinding temperature is not higher than 35°C, and pulverizing the menthol until the particle size D90 value is less than 380um; adding the prepared menthol powder, WS-23 and polysorbate into glycerin under the condition of stirring, fully Stir to obtain an oil phase solution;

[0053] Add the sweetener, preservative, and essence into purified water to dissolve and stir to obtain an aqueous phase solution;

[0054] Slowly add the prepared oil phase solution into the stirring water phase solution, control the linear velocity to 0.4-1.0 m / s, and stir at a speed of 600-800 rpm for 30-50 minutes to obtain mouthwash.

Embodiment 3

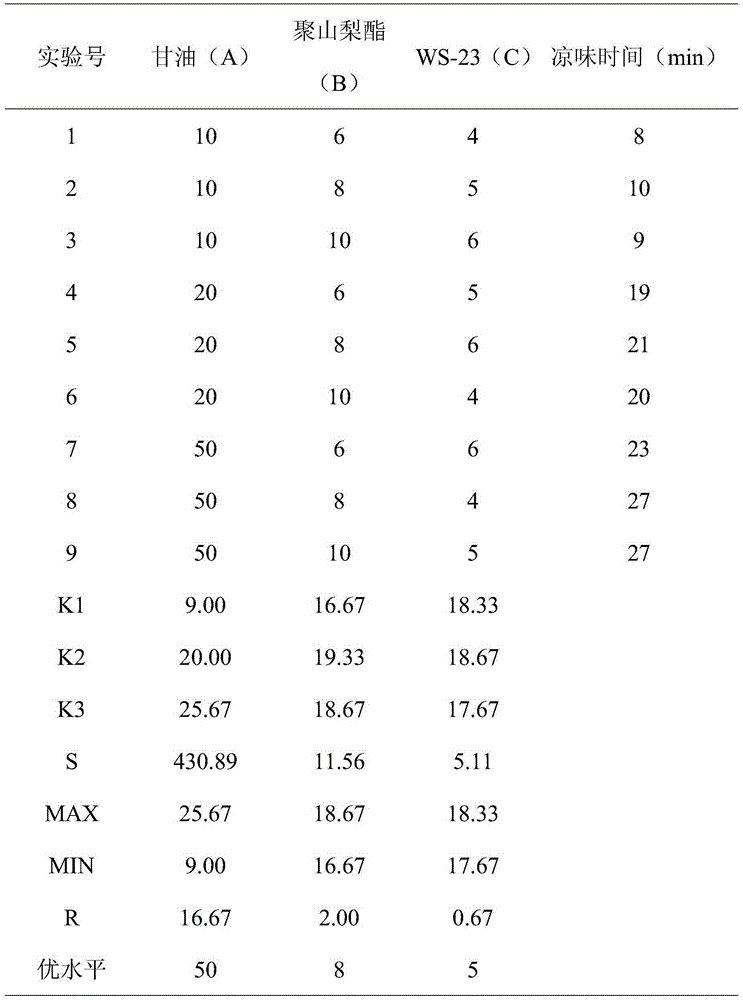

[0056] WS-23: 5 parts by weight, Menthol: 10 parts by weight, Polysorbate: 8 parts by weight, Glycerin: 50 parts by weight, Sweetener: 30 parts by weight, Preservative: 0.6 parts by weight, Flavor: 0.8 parts by weight, Pure water: 850 parts by weight;

[0057] Preparation: Grinding menthol at low temperature, the grinding temperature is not higher than 35°C, and pulverizing the menthol until the particle size D90 value is less than 380um; adding the prepared menthol powder, WS-23 and polysorbate into glycerin under the condition of stirring, fully Stir to obtain an oil phase solution;

[0058] Add the sweetener, preservative, and essence into purified water to dissolve and stir to obtain an aqueous phase solution;

[0059] Slowly add the prepared oil phase solution into the stirring water phase solution, control the linear velocity to 0.4-1.0 m / s, and stir at a speed of 600-800 rpm for 30-50 minutes to obtain mouthwash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com