Ultrasonic phased array imaging detection method for steam turbine blade root bolt holes

A steam turbine blade and ultrasonic phased array technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve problems such as the ultrasonic phased array detection method for bolt holes without fork-shaped blade roots, and achieves reduction of learning costs and savings. Time cost, the effect of saving assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described in conjunction with the following examples.

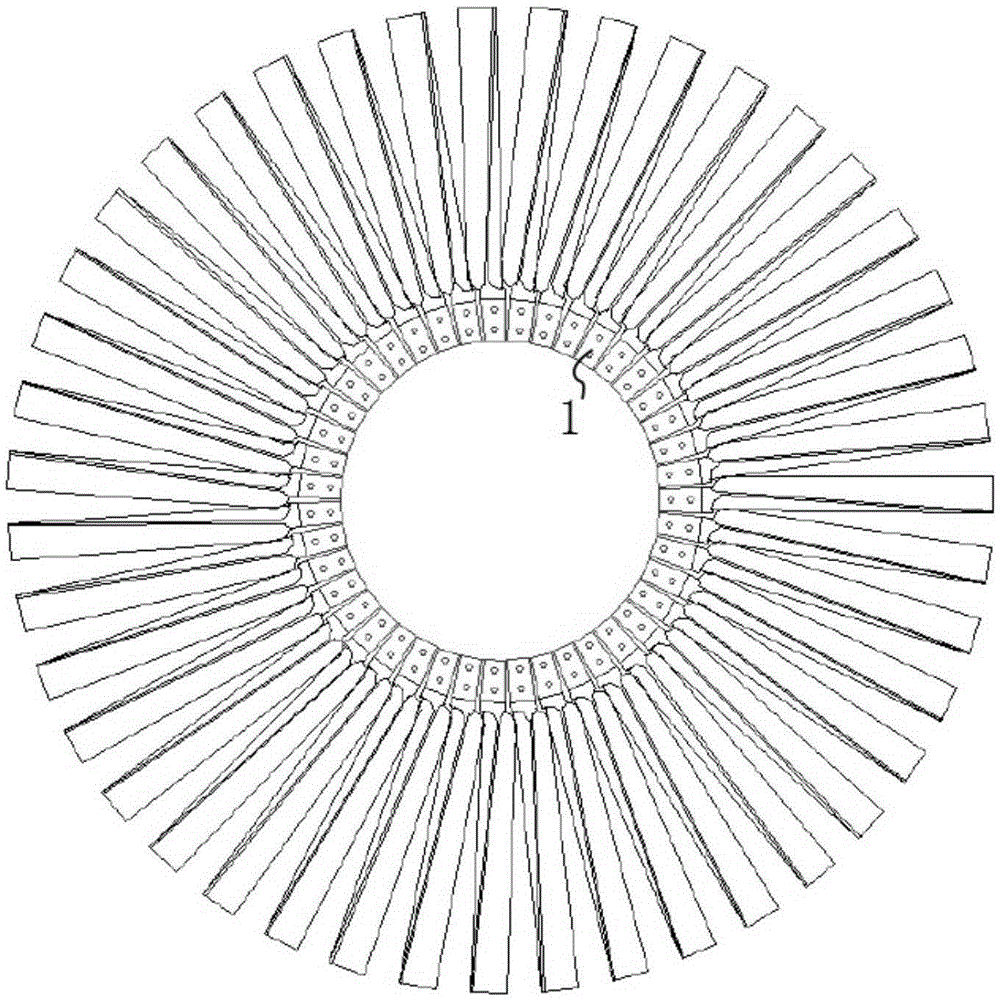

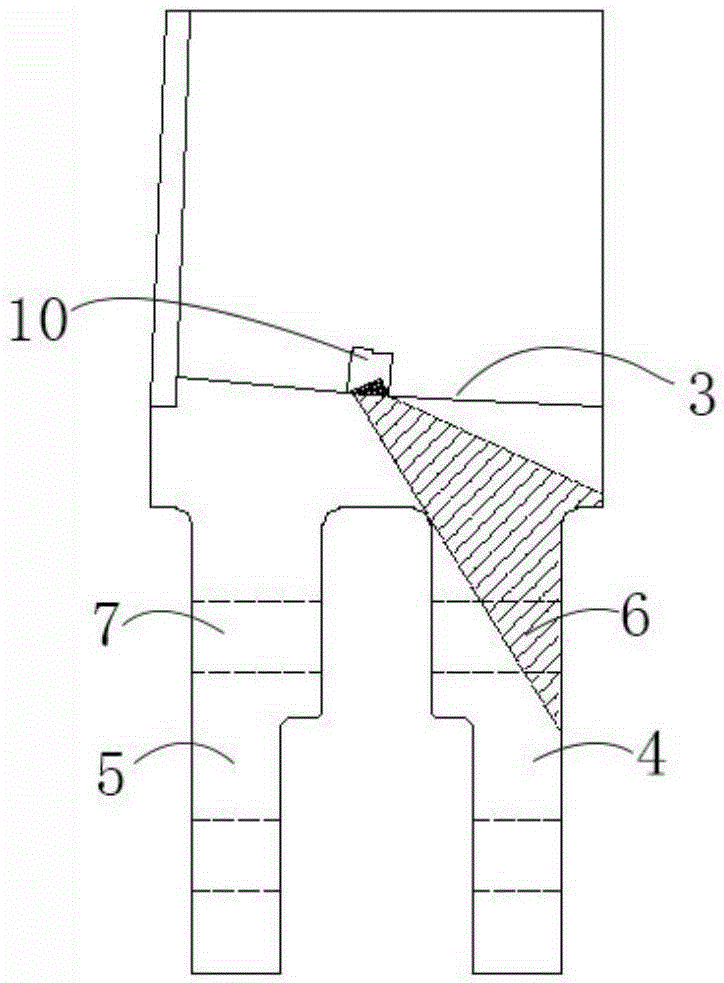

[0033] An ultrasonic phased array imaging detection method for bolt holes at the root of a steam turbine blade, wherein the root of the blade is a fork-shaped blade root. In the related art, the fork-shaped blade root is divided into two-pronged blade roots, three-pronged blade roots, four-pronged blade roots, and seven-pronged blade roots according to the number of fork teeth. . However, no matter how many fork-shaped blade roots have, compared with the fork teeth arranged in the middle, the front fork teeth arranged at the front and the rear fork teeth arranged at the back receive the greatest stress, and the stress is concentrated Bolt holes at the top of the front and rear forks. Therefore, the inspection generally focuses on the bolt holes at the top of the front fork and rear fork.

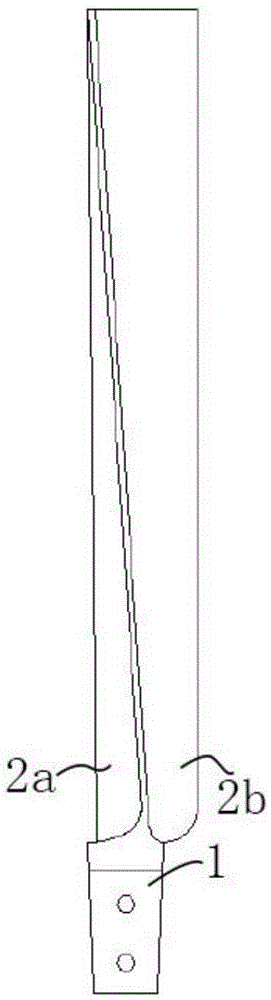

[0034] In this example, if figure 1 with figure 2 As shown, the fork-shaped blade root 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com