Vibration-state on-line monitoring method of high-voltage motor driving conveying belt

A high-voltage motor and conveyor belt technology, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems that the timeliness of information cannot be guaranteed, and the running status of high-voltage motors cannot be monitored timely and accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

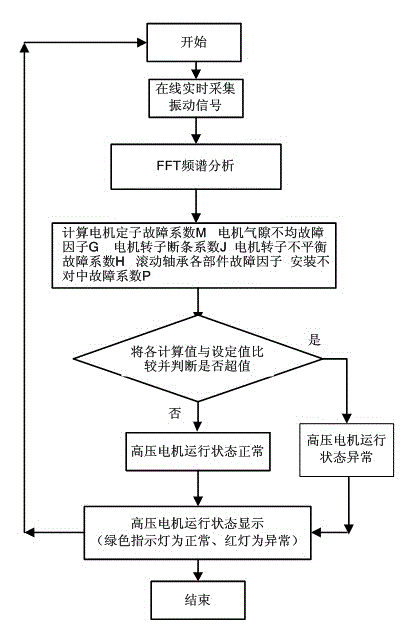

[0045] Such as figure 1 As shown, the on-line monitoring method of the vibration state of the high-voltage motor driving the conveyor belt of the present invention comprises the following steps:

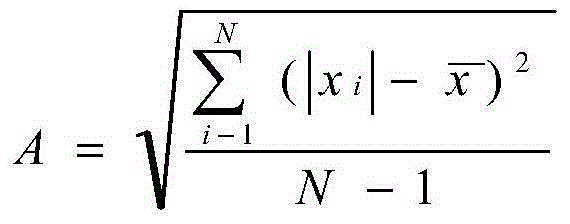

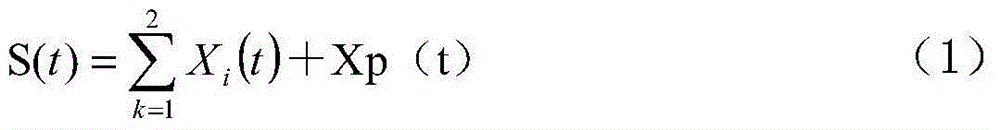

[0046] Step 1. Install vibration sensors for outputting vibration signals on each bearing seat of the high-voltage motor, and collect the original vibration signals output by the vibration sensors X i , for the original vibration signal X i Perform frequency spectrum analysis to extract the vibration characteristic signal of the high-voltage motor. The total vibration value A of the original vibration signal is determined by the discrete value X of the vibration signal i (i=1,2,……,N) get,

[0047] A = Σ i - 1 N ( | ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com