Liquid level measurement instrument

A liquid level measurement and sensor technology, which is applied to instruments, liquid/fluid solid measurement, measurement devices, etc., can solve the problems that the control circuit cannot be intelligently protected, the structure design is unreasonable, and the personnel requirements are high, so as to achieve long-term effectiveness of protection and reduce The cost of personnel requirements and the effect of simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

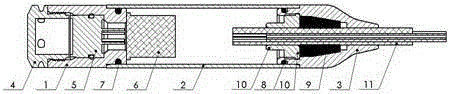

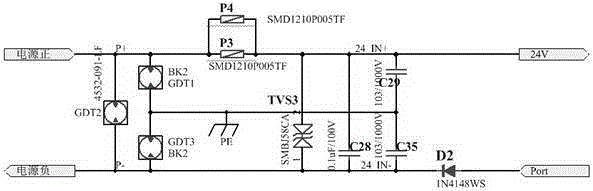

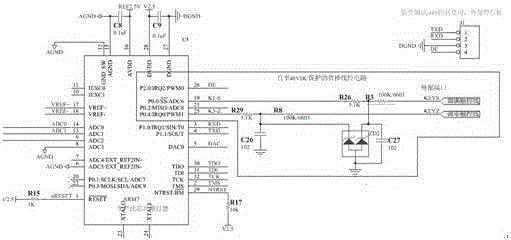

[0017] see Figure 1~Figure 3 , a liquid level measuring device, including a tube body, a sensor base, a protective cover, a sensor, a rear cover, an outgoing cable, a circuit board, and a pressure ring, a sensor base is provided at one end of the tube body, and a protective cover is provided outside the sensor base , the other end of the pipe body is provided with a back cover, and the outlet cable is arranged through the back cover, and the outlet cable and the back cover are pressed and connected by a pressure ring. The sensor base is provided with a sensor, and the rear side of the sensor is provided with a circuit board. , the sensor base is connected to the tube body by laser welding, and the seam is the first laser welding point. The oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com