Membrane auxiliary type compression bar destabilizing trigger type pressure relief device applied to micro-pressure working condition

A technology of pressure relief device and diaphragm, which is applied in the direction of valve operation/release device, valve device, engine components, etc., and can solve the problem of no diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

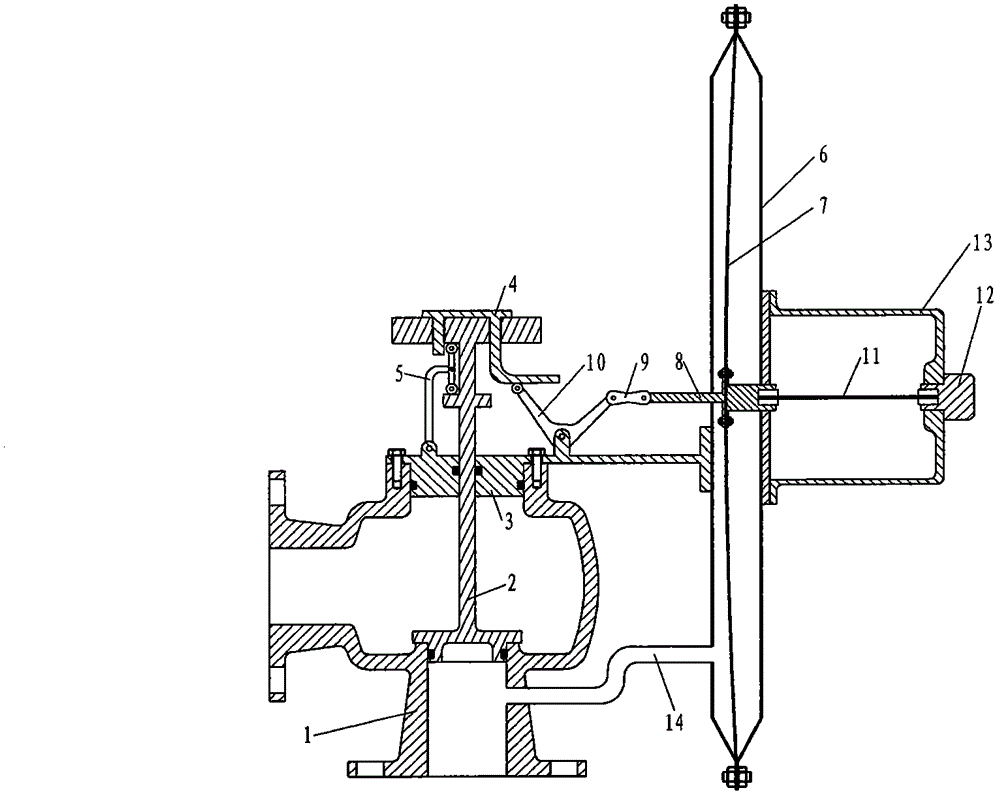

[0011] A diaphragm-assisted pressure rod instability trigger type pressure relief device suitable for micro-pressure conditions, the main components include valve body 1, valve disc 2, valve cover 3, lock arm 4, lock buckle 5, and diaphragm housing 6. Diaphragm 7, connecting rod 8, hinge 9, linkage rotating arm 10, slender rod 11, nut 12, rod cage 13 and pressure communication pipe 14. See figure 1 .

[0012] Wherein, the locking arm 4, the locking buckle 5, the diaphragm 7, the connecting rod 8, the hinge 9, the linkage rotating arm 10, and the slender rod 11 jointly constitute the trigger mechanism of the device. The elongated rod 11 is the trigger part of the device, and one end thereof is connected with the connecting rod 8 , and the other end is connected with the nut 12 installed on the rod cage 13 .

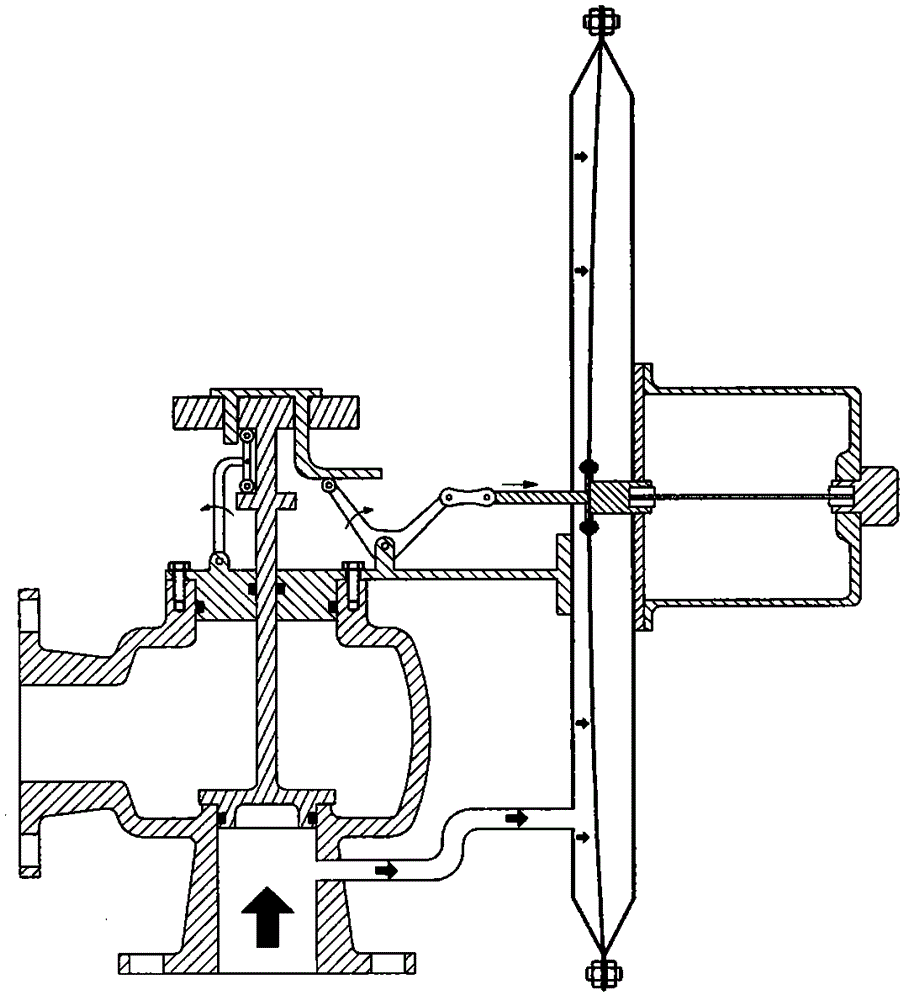

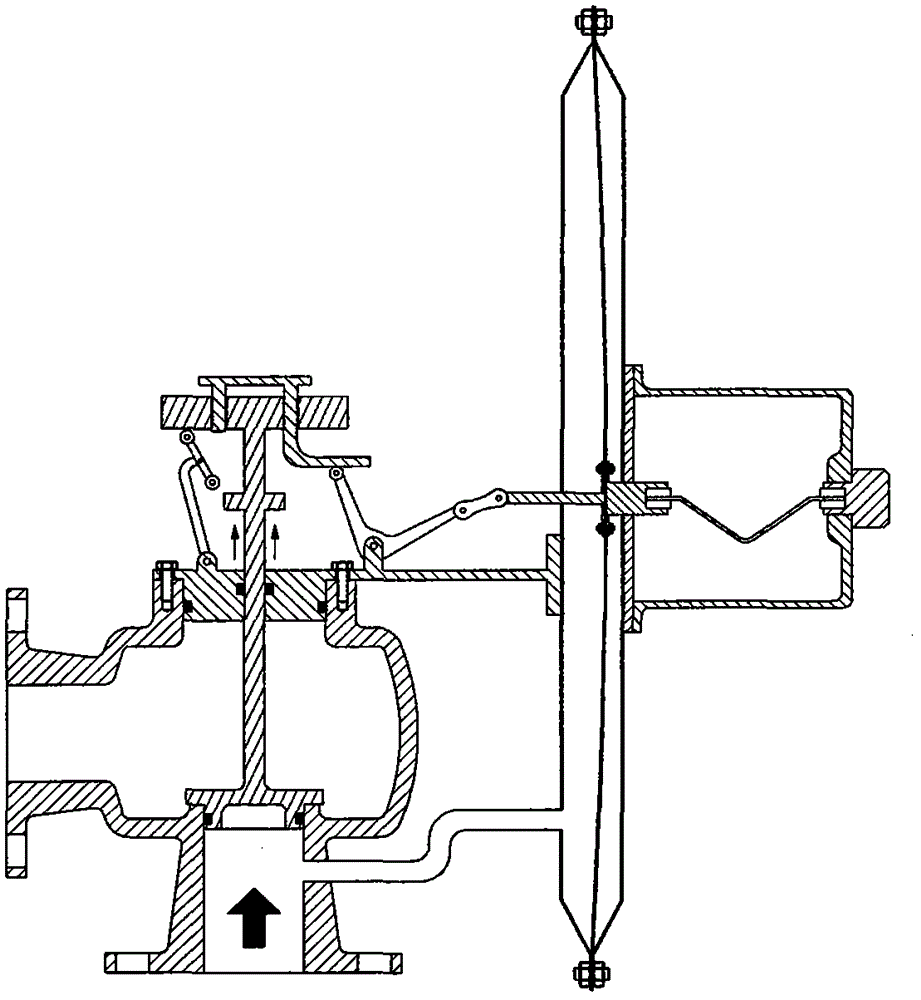

[0013] The medium pressure enters the diaphragm housing 6 through the pressure communication pipe 14 and acts on the diaphragm 7 to generate a thrust load. The thrust lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com