Hydraulic independent heat dissipation control method, device and system

A cooling system, hydraulic technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of slow response speed of cooling system and inaccurate response results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

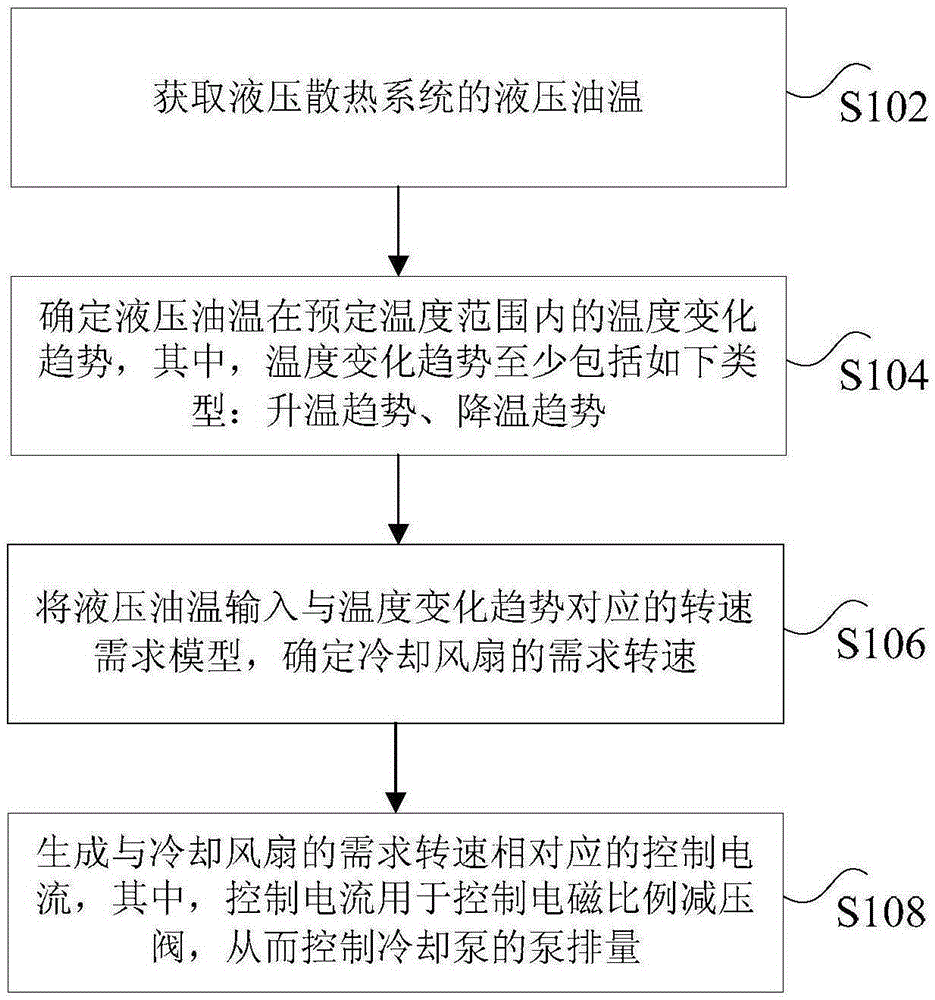

[0021] According to an embodiment of the present invention, an embodiment of a method for controlling hydraulic independent heat dissipation is provided. It should be noted that the steps shown in the flowcharts of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, and , although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

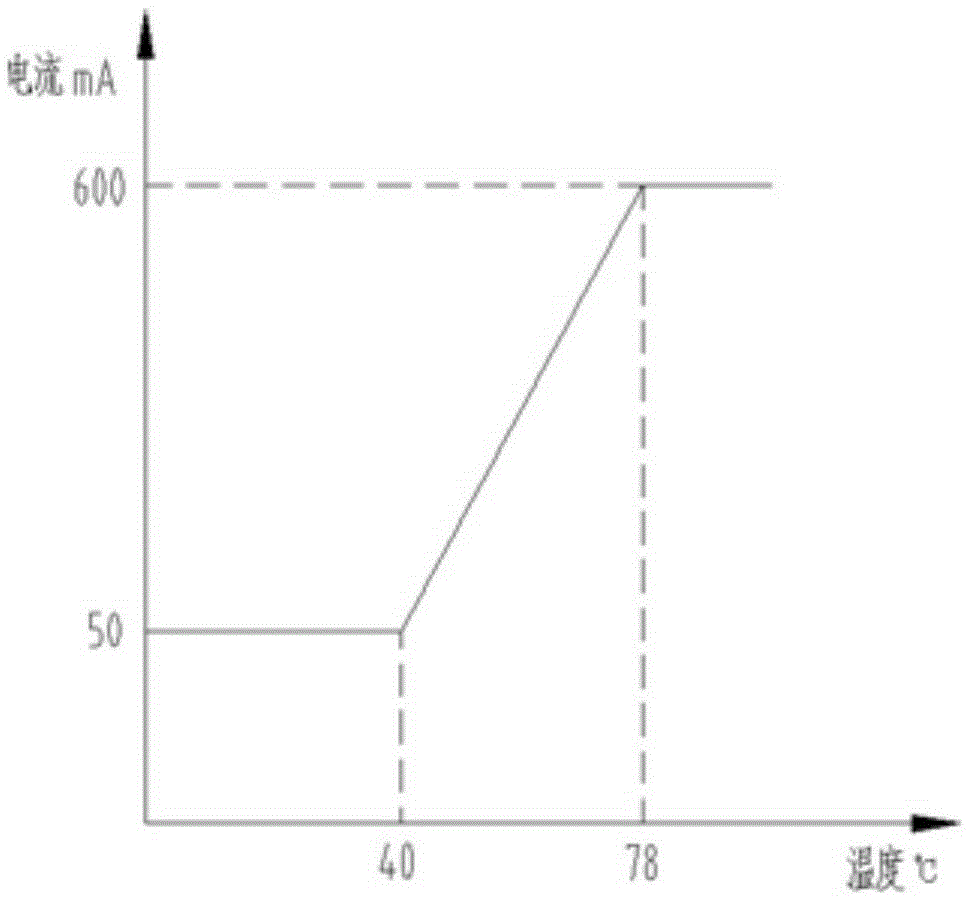

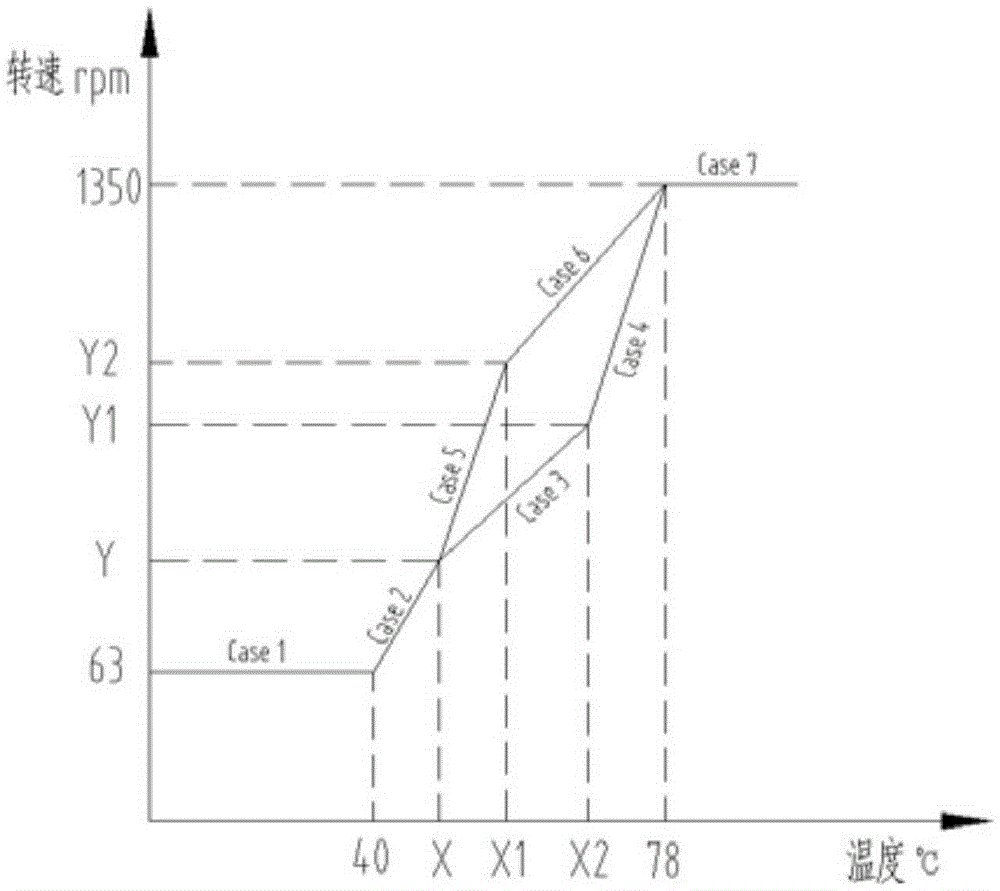

[0022] figure 2 It is a flow chart of the hydraulic independent heat dissipation control method according to Embodiment 1 of the present invention, as shown in figure 2 As shown, the method includes the following steps:

[0023] Step S102, acquiring the hydraulic oil temperature of the hydraulic cooling system.

[0024] As an optional embodiment, a temperature sensor may be used to detect the hydraulic oil temperature.

[0025] Step S104, determining the temperature change...

Embodiment 2

[0080] According to an embodiment of the present invention, an embodiment of a hydraulic independent heat dissipation control device is also provided.

[0081] Figure 5 is a schematic structural diagram of a hydraulic independent heat dissipation control device according to Embodiment 2 of this law.

[0082] Such as Figure 5 As shown, the device for acquiring push data may include: a first acquiring module 50 , a first determining module 52 , an input module 54 and a generating module 56 .

[0083] The first acquiring module 50 is configured to acquire the hydraulic oil temperature of the hydraulic cooling system.

[0084] The first determination module 52 is configured to determine a temperature change trend of the hydraulic oil temperature within a predetermined temperature range, wherein the temperature change trend includes at least the following types: a temperature rise trend and a temperature drop trend.

[0085] Specifically, in the above-mentioned device, the pre...

Embodiment 3

[0130] According to an embodiment of the present invention, a hydraulic independent heat dissipation control system is also provided, such as Figure 6 As shown, the system may include: a cooling pump 1, a cooling fan 4, an electromagnetic proportional pressure reducing valve 2, a hydraulic oil temperature sensor and a controller, wherein,

[0131] Cooling pump 1.

[0132] Cooling fan 4.

[0133] Specifically, such as Figure 6 As shown, in the above system, the cooling fan 4 is connected with the cooling motor 3 and rotates according to the control of the cooling motor to reduce the temperature of the hydraulic oil.

[0134] The electromagnetic proportional pressure reducing valve 2 is connected with the cooling pump 1 and is used to control the pump displacement of the cooling pump.

[0135] Specifically, such as Figure 6 As shown, in the above system, the electromagnetic proportional pressure reducing valve 2 is connected with the cooling pump 1 to control the pump dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com