Linear compressor, housing of linear compressor, and manufacturing method of the housing

A technology of linear compressor and manufacturing method, which is applied to machines/engines, mechanical equipment, liquid variable-capacity machines, etc., can solve the problem of inability to apply high-speed operating frequency, etc., to reduce noise generation, reduce noise, and improve discomfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

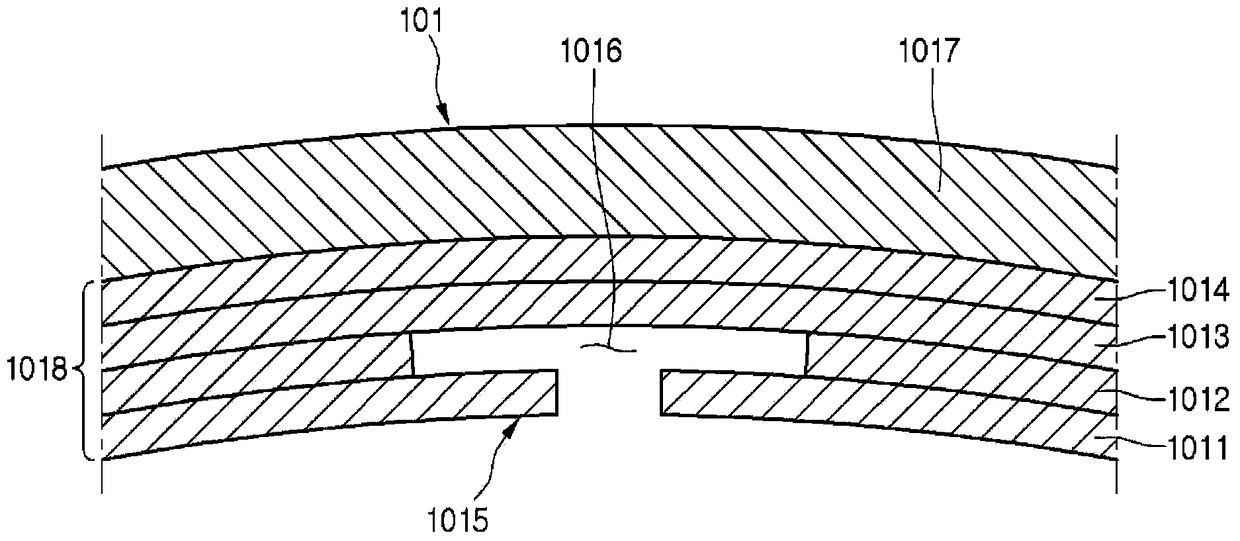

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the concept of the present invention is not limited to the embodiments provided below, and other embodiments should be easily provided through addition, modification, deletion, and addition of constituent elements, and these embodiments should also be included in the concept of the present invention .

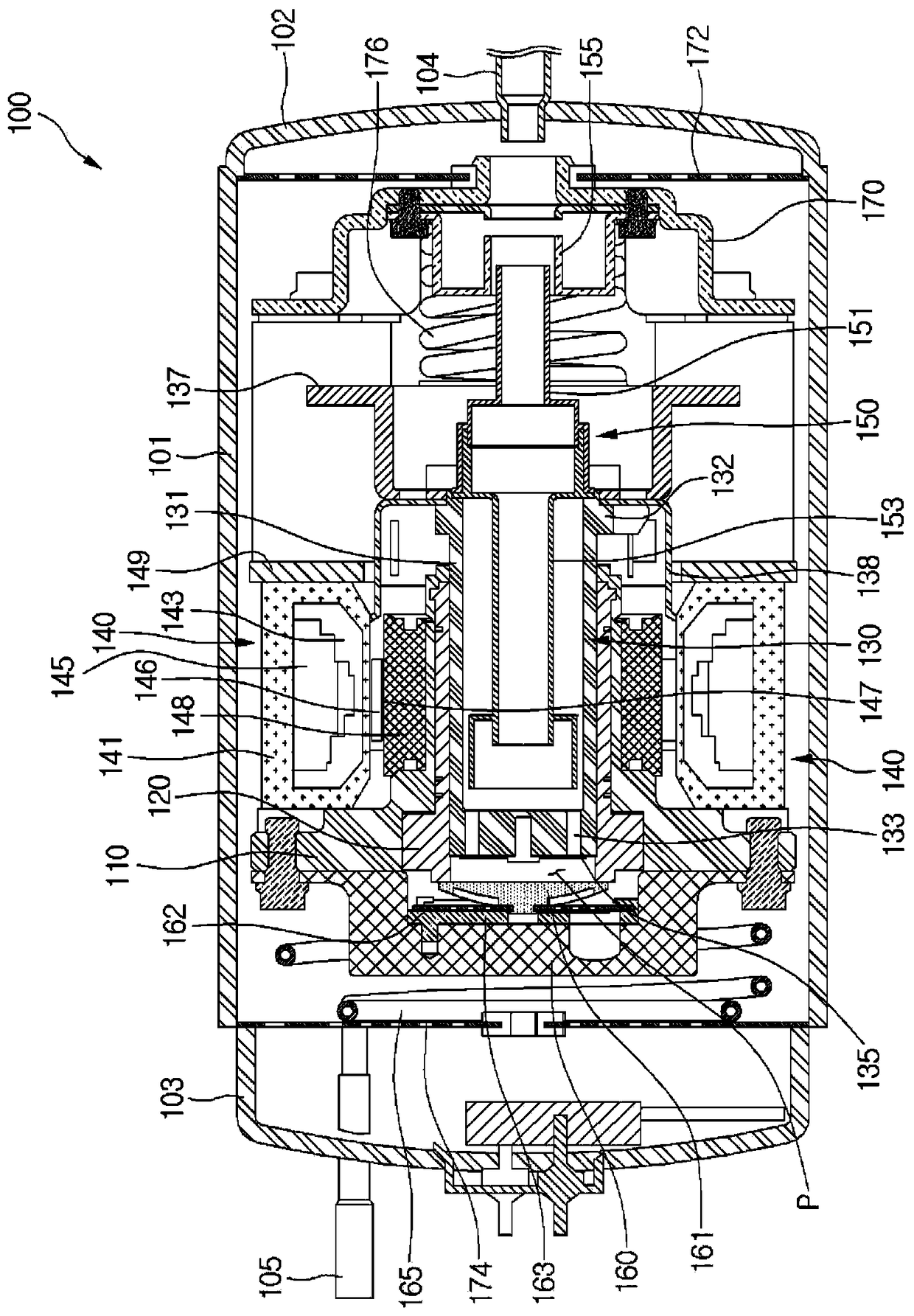

[0034] figure 1 is a sectional view of the linear compressor according to the embodiment.

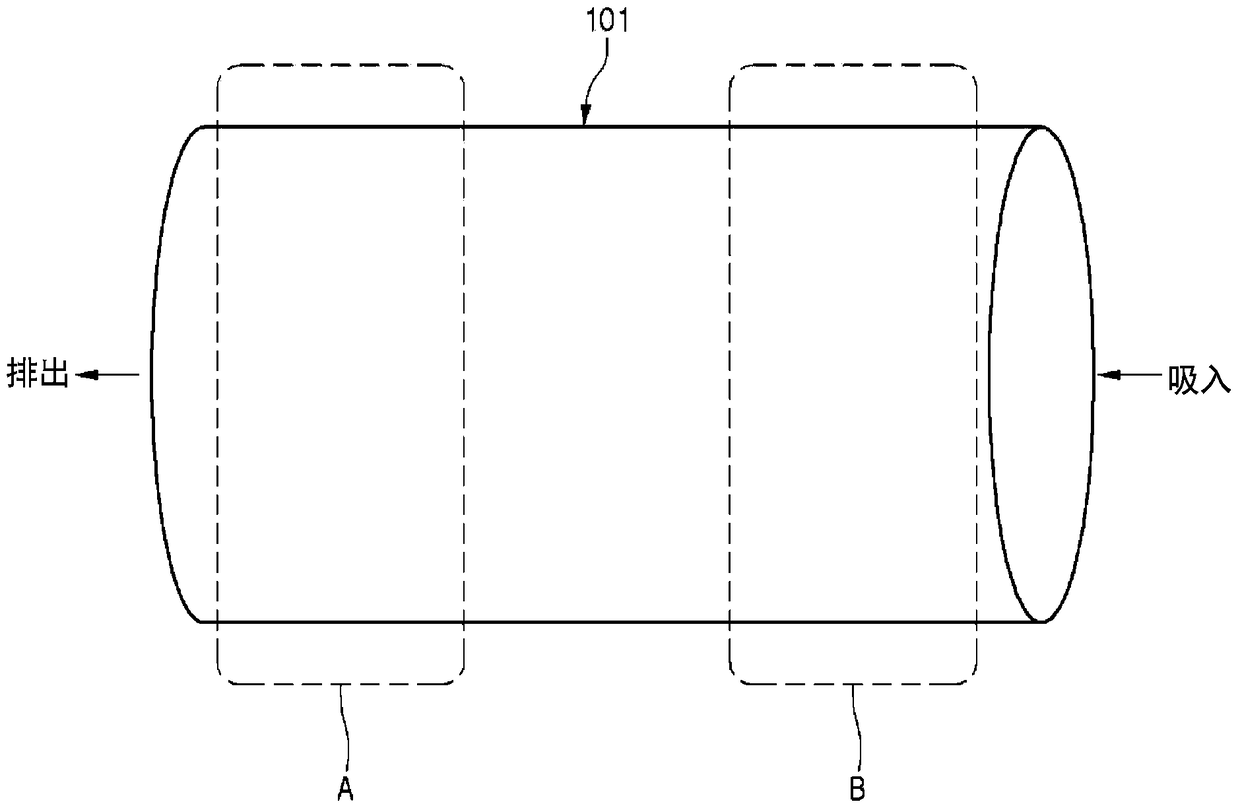

[0035] like figure 1 As shown, the linear compressor 100 according to the embodiment includes: a cylindrical shell 101; a first cover 102 combined with one side of the shell 101; The second cover 103 . As an example, the linear compressor 100 can be arranged horizontally, the first cover 102 can be combined on the right side of the casing 101, and the second cover 103 can be combined on the The left side of the housing 101.

[0036] Since th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com