Manufacturing method of steel and wood burglarproof door

A production method and technology of anti-theft doors, which are applied in the fields of preventing theft, preventing war damage, soundproof doors/windows, etc., can solve the problems of uncoordinated colors, textures, low grades, and single styles of anti-theft doors, etc., so as to make up for the lack of anti-theft performance , prevent damage, and solve the effect of not being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

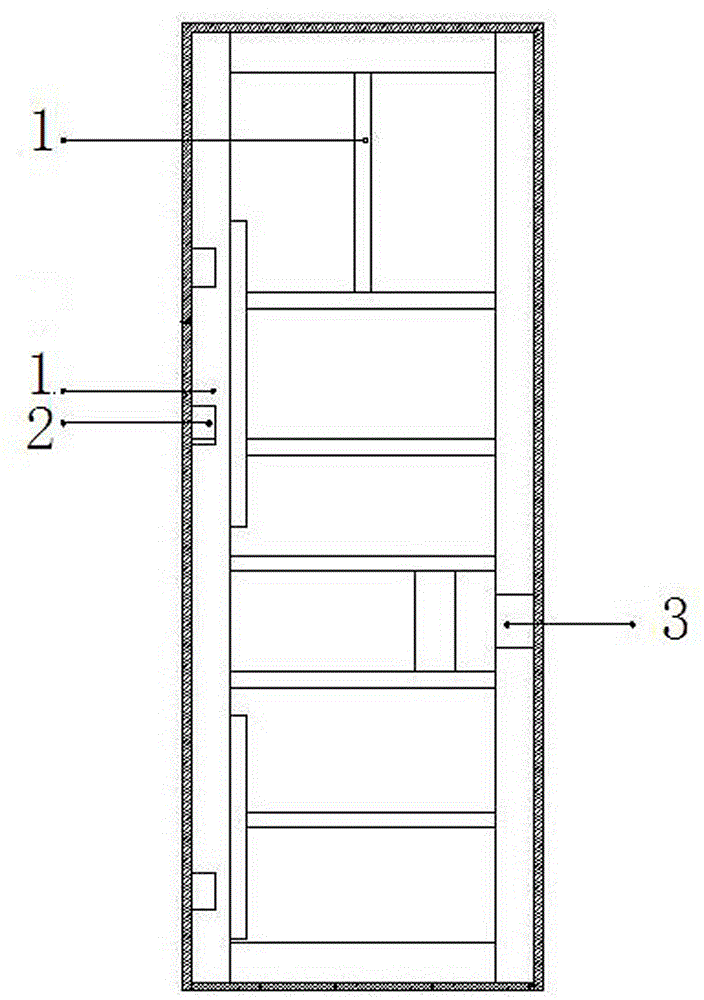

[0038] Step 1: Production of door leaf metal frame 1: 30mmx100mmx2-2.5mm square pipes are used on the door side; 30mmx50mmx2mm-2.5mm square pipes are used for the upper and lower docks; 30mmx30mmx2.0mm-2.5mm square pipes are used for the internal name, door hinges 2 Add a 30mmx30mmx2.0mm-2.5mm square tube to the opening to strengthen, the keyhole is especially strengthened, the welding port is polished smoothly, and the metal door frame is sealed with 15mm thick solid wood; figure 1 .

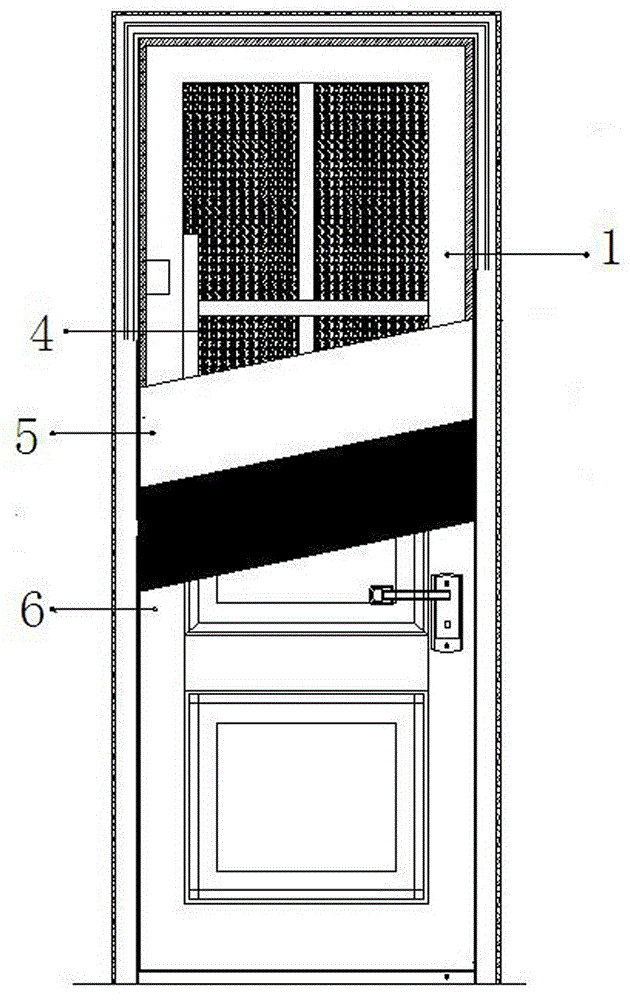

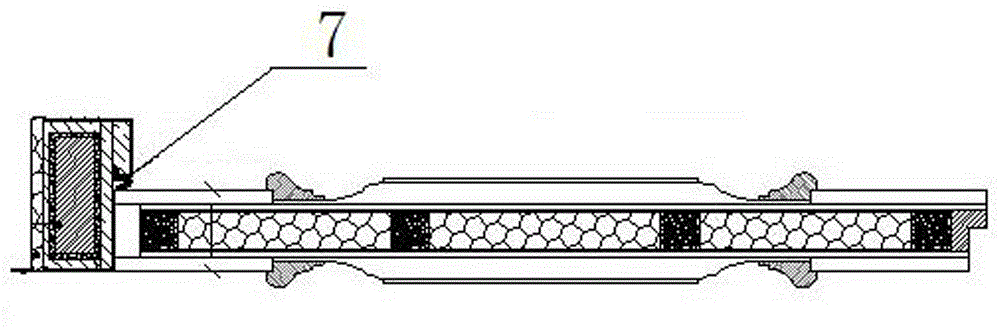

[0039] The second step: heat preservation treatment: the door leaf metal frame 1 obtained above is filled with rock wool 4, double-sided sealed 0.8mm-1mm round hole metal plate 5 and 5mm solid wood multilayer board, and the treatment is smooth and smooth.

[0040] The third step: Finishing: The panel adopts carbonized red oak board or other wood species with good texture of carbonized wood 6,10mm-15mm thick. The shape is processed according to the drawings, and it is glued and bound on the above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com