Drainpipe for drum type washing machine and preparation method thereof

A technology for a drum washing machine and a drainage pipe, which is applied in the field of drum washing machines, can solve the problems of poor dynamic performance, easy deformation, and poor deformation resistance of the drainage pipe, and achieves improved shock absorption and sealing effect, excellent deformation resistance, and long life. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

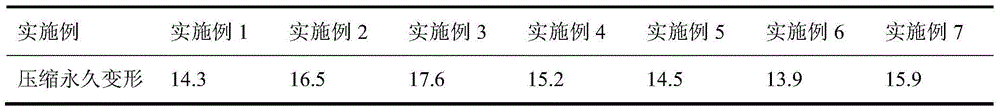

Examples

Embodiment 1

[0052] First, 160 parts of EPDM rubber, 130 parts of carbon black, 40 parts of paraffin oil, 5 parts of indirect method zinc oxide, 1.5 parts of anti-aging agent, 3 parts of lubricant, 2 parts of auxiliary crosslinking agent and 3 parts of The vulcanizing agent is placed in an internal mixer for mixing to obtain synthetic rubber.

[0053] Next, the above-mentioned synthetic rubber is extruded and molded after being uniformly heated by an open mill, and then the extruded rubber strip is injected into the mold in the vulcanization equipment, and the pressure is 190Kgf / cm 2 , the temperature was raised to 175°C, and the vulcanization treatment was carried out for 360 seconds.

[0054] Finally, the drain pipe obtained after the vulcanization treatment is trimmed, inspected, packaged and put into storage to obtain the drain pipe.

Embodiment 2

[0056] The raw material composition of synthetic rubber is: 175 parts of EPDM rubber, 130 parts of carbon black, 40 parts of paraffin oil, 5 parts of indirect zinc oxide, 1.5 parts of anti-aging agent, 3 parts of lubricant, 2 parts of auxiliary crosslinking agent and 3 parts of Part vulcanizing agent, except that, other conditions are all with embodiment 1.

Embodiment 3

[0058] The raw material composition of synthetic rubber is: 190 parts of EPDM rubber, 130 parts of carbon black, 40 parts of paraffin oil, 5 parts of indirect zinc oxide, 1.5 parts of anti-aging agent, 3 parts of lubricant, 2 parts of auxiliary crosslinking agent and 3 parts of Part vulcanizing agent, except that, other conditions are all with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com