Polycarbonate synthesis process

A polycarbonate and synthetic process technology, applied in the field of chemistry, can solve problems such as environmental pollution and poor natural degradability, and achieve the effects of reducing costs, high recycling rate, and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

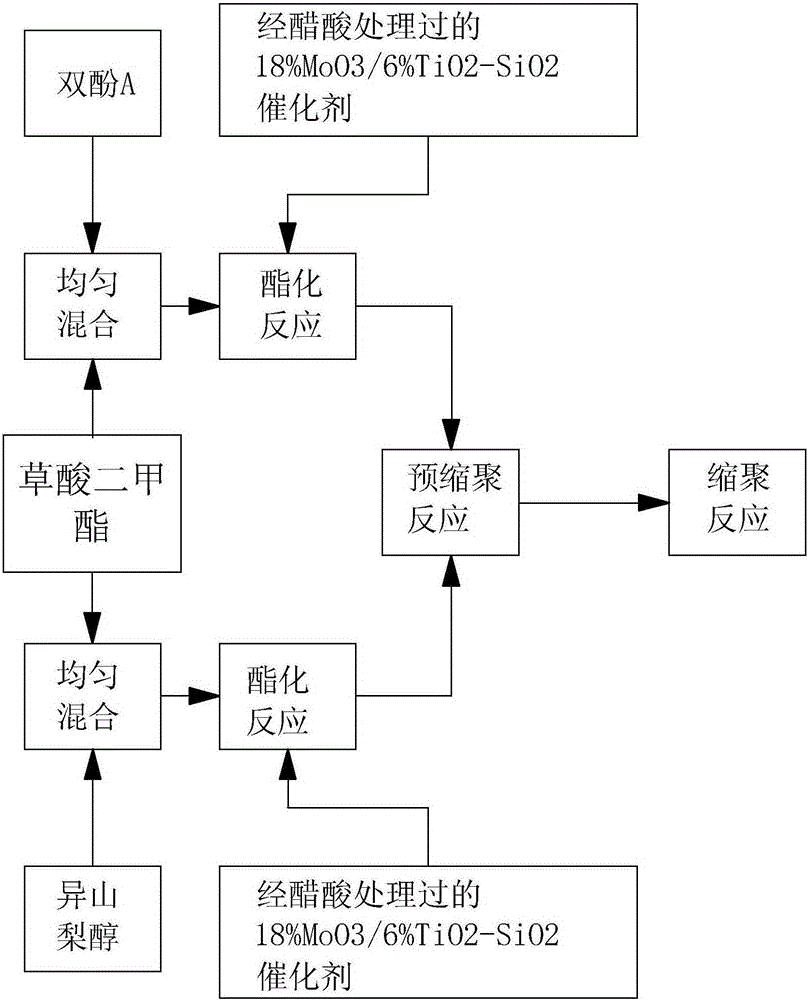

[0017] refer to figure 1 Embodiments of the present invention will be further described.

[0018] A kind of polycarbonate synthesis technique, comprises the following steps:

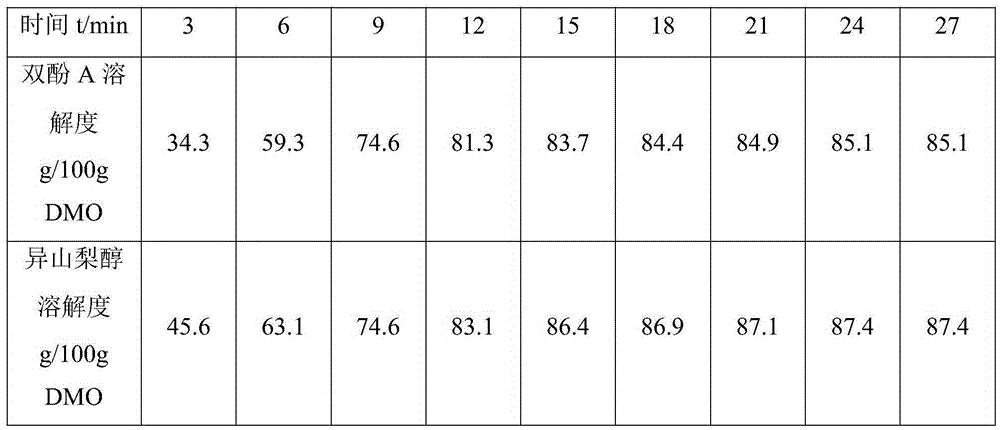

[0019] Step 1. Melt dimethyl oxalate at a temperature of 54°C to 59°C and a pressure of 100kPa to 150kPa, and uniformly mix bisphenol A and isosorbide with the molten dimethyl oxalate to form a mixture, During this process, the molar ratio of dimethyl oxalate to bisphenol A is 0.90-1.35, and the molar ratio of dimethyl oxalate to isosorbide is 0.95-1.5;

[0020] Step 2. Add 18% MoO treated with acetic acid to the two mixtures in step 1 3 / 6%TiO 2 -SiO 2 Catalyst, and keep the temperature of the two mixtures at 65 ℃ ~ 70 ℃, the pressure is 5kPa ~ 60kPa for esterification reaction, 18% MoO treated with acetic acid 3 / 6%TiO 2 -SiO 2 The molar ratio of catalyst to dimethyl oxalate is 1×10 -9 ~5×10 -5 ;

[0021] Step 3, mixing the two mixtures after the esterification reaction in step 2 again to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com