Multi-component potassium magnesium phosphate cement

A potassium magnesium phosphate cement, multi-component technology, applied in the field of cement, can solve the problems of easy formation of cracks, high thermal expansion coefficient, large hydration heat release, etc., to achieve improved shrinkage performance, compact crystal accumulation, less cracks and defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A multi-component potassium magnesium phosphate cement including 34% KH 2 PO 4 , 49%MgO, 7.2%Al (H 2 PO 4 ) 3 , 4.9% glass fiber, 1% sodium carboxymethyl cellulose, 1.2% phosphate monoester coupling agent, 0.4% sodium tripolyphosphate and 1.3% sodium ethylenediamine tetramethylene phosphonate.

Embodiment 2

[0036] A multi-component potassium magnesium phosphate cement including 40% KH 2 PO 4 , 43%MgO, 8.8%Al (H 2 PO 4 ) 3 , 3.3% glass fiber, 1.8% sodium carboxymethylcellulose, 0.4% phosphate monoester coupling agent, 0.8% sodium tripolyphosphate and 0.9% sodium ethylenediamine tetramethylene phosphonate.

[0037] The particle size of the magnesium oxide particles is 86 μm, and the specific surface area of the magnesium oxide particles is 1737 cm 2 / g.

[0038] The particle size of the potassium dihydrogen phosphate particles is 130 μm, and the specific surface area of the potassium dihydrogen phosphate is 2110 cm 2 / g.

[0039] The particle size of the aluminum dihydrogen phosphate particles is 90 μm, and the specific surface area of the aluminum dihydrogen phosphate is 2320 cm 2 / g.

Embodiment 3

[0041] A multi-component potassium magnesium phosphate cement including 37% KH 2 PO 4 , 46%MgO, 9%Al (H 2 PO 4 ) 3 , 4.1% glass fiber, 1.4% sodium carboxymethylcellulose, 0.8% phosphate monoester coupling agent, 0.6% sodium tripolyphosphate and 1.1% sodium ethylenediamine tetramethylene phosphonate.

[0042] The particle size of the magnesium oxide particles is 86 μm, and the specific surface area of the magnesium oxide particles is 1737 cm 2 / g.

[0043] The particle size of the potassium dihydrogen phosphate particles is 130 μm, and the specific surface area of the potassium dihydrogen phosphate is 2110 cm 2 / g.

[0044] The particle size of the aluminum dihydrogen phosphate particles is 90 μm, and the specific surface area of the aluminum dihydrogen phosphate is 2320 cm 2 / g.

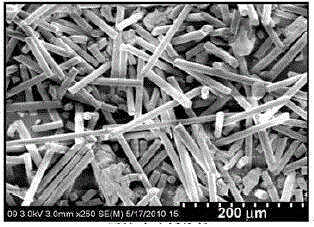

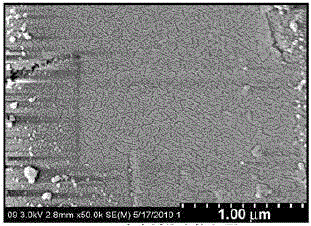

[0045] Glass fiber as nano TiO 2 / micron composite glass fiber, nano / micron TiO 2 Glass fibers are layered, including TiO 2 Porous coating formed on glass fiber surface, TiO 2 The par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com