A method of making a simple double-track gantry crane

A manufacturing method and gantry crane technology, applied in the field of gantry cranes, can solve the problems of large installation area, unsuitable gantry cranes, heavy gantry cranes, etc., and achieve the effects of simple manufacturing, simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Located 70 kilometers south of Tangshan City, Hebei Province, the industrial plant in Caofeidian area has a large amount of construction and a long construction period, and the construction site is far away from the fixed steel structure processing plant. In order to facilitate the processing and transportation of components, it is necessary to build a temporary processing plant and material storage yard on the construction site And need more lifting equipment. Combined with the actual situation of the construction site, existing materials and engineering needs, the gantry cranes will be manufactured and installed on site. The gantry crane of the invention should meet the requirements of structural strength, meet the construction requirements of operation performance, be simple to manufacture, fast to install, fast and compact to transport, long service life and easy to maintain.

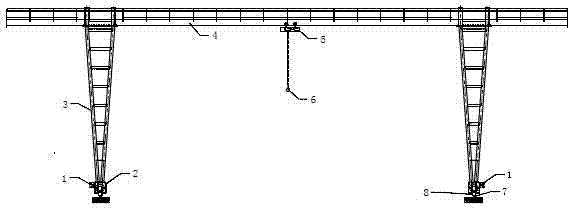

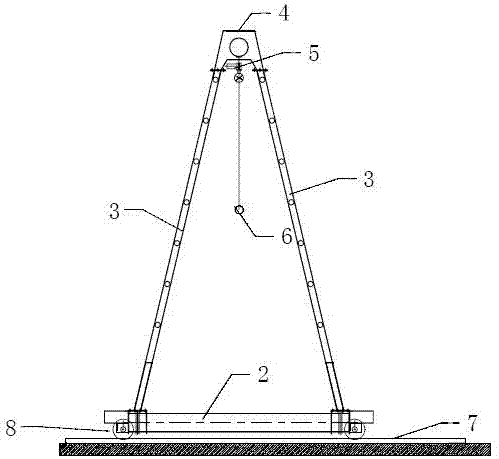

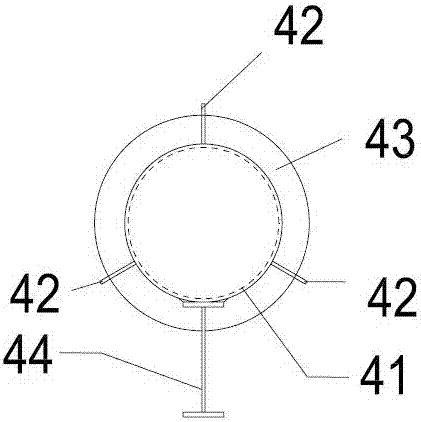

[0038] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com