Application and design method of an early warning management system for CDQ hoist operation

A design method and management system technology, applied in transportation and packaging, coke cooling, coke ovens, etc., can solve the problems of difficulty in analyzing failures, time-consuming, and high technical requirements, reducing troubleshooting time and achieving good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

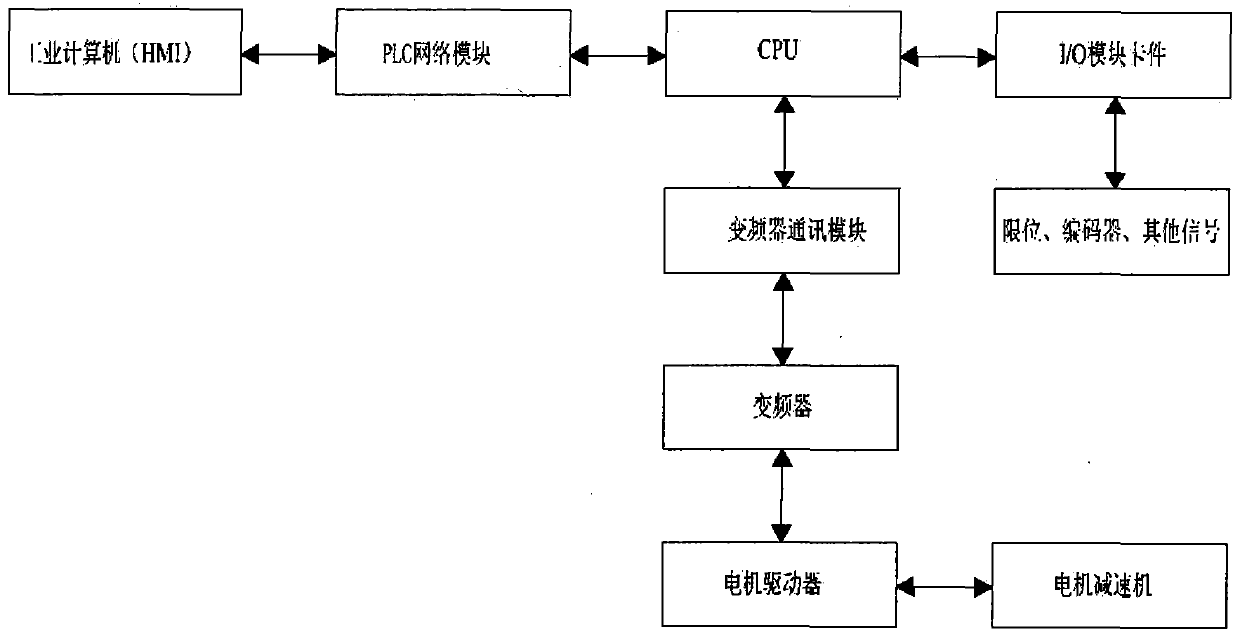

[0037] combined with Figure 4 , a CDQ hoist operation warning management system of the present invention, including a signal acquisition structure and an automatic processing system:

[0038] combined with image 3 , the signal acquisition structure includes each position close to the limit 1, hoist encoder 2, travel encoder 3, hoist motor inverter communication module 4, travel motor inverter communication module 5, hoist wire rope drum 6, travel motor deceleration Machine 7; each selected position close to the limit 1 is a product of Pepperl+Fuchs (P+F) in Germany, model: SJ30-A210-30VDC. The limit is durable, the signal is stable, and the anti-interference ability is strong. The hoist encoder 2 is installed on the wire rope drum 6 of the hoist, and the hoist encoder 2 selected is a Baumer encoder, model: FGHJ4K-1024-90 / 20P473189. The traveling encoder 3 is installed on the side of the traveling motor reducer 7, the selected traveling encoder 3 is a Baumer encoder, model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com