An instant hot water dispenser heating body

A heating body and water dispenser technology, applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of large gaps in the flow channel, only boiled water can be discharged, and the temperature can not be adjusted for heating, so as to ensure the heat absorption effect and realize the performance , the effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

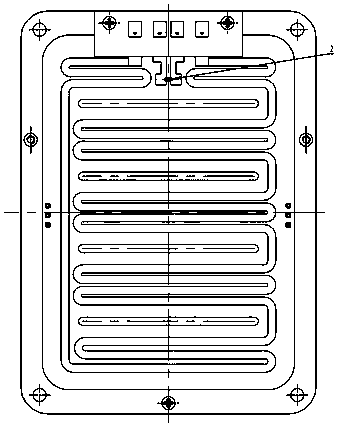

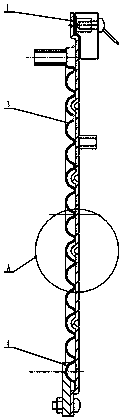

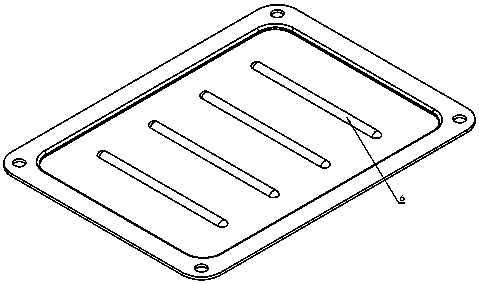

[0022] A heating body of an instant water dispenser is composed of a metal substrate electric heating film 1, a thermistor 2, a flow channel plate 3, and a heat sink 4. In order to solve the problem of deformation of the electric heating film during processing and use, the characteristic is that the electric heating film Ribs are processed on the metal substrate, such as image 3 , the flow channel is processed on the flow channel plate, such as Figure 4 After assembly, the reinforcing ribs on the metal substrate of the electrothermal film and the flow channels on the flow channel plate form an S-shaped cavity flow channel, such as figure 1 , figure 2 and Figure 4 , there are two shapes for the cross section of the flow channel, one is formed by the flow channel of the flow channel plate and the flat part of the electrothermal film, the shape is approximately semicircular, the cross-sectional area of the flow channel is a key parameter of the heating body, if the cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com