Turbine with hydraulic variable pitch system

A technology of hydraulic system and pitch control system, which is applied to propellers, engines, mechanical equipment, etc., and can solve problems such as large pitch control system, reduced turbine reliability, and reduced energy extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

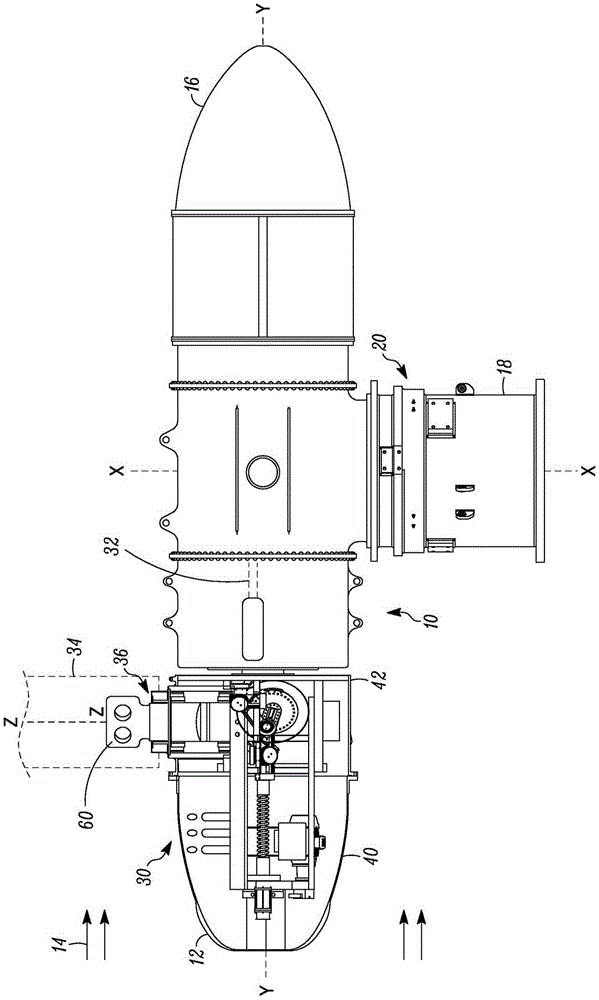

[0019] figure 1 The turbine 10 described herein is shown. The turbine 10 is designed to be positioned relative to a flowing fluid so as to be driven by the fluid. In one embodiment, the turbine 10 is submerged in water experiencing tidal flow. However, the turbine 10 may be submerged in any body of water (eg, river water) where there is a flow of water that may be used to generate electrical power. The concepts described herein may also be employed on wind driven turbines.

[0020] In use, the turbine 10 includes a front end 12 facing a flowing fluid indicated by arrow 14 and a rear end 16 . The turbine 10 is supported by a support structure 18 . Optionally, the yaw drive mechanism 20 may be arranged to rotate the turbine 10 about an axis X-X (which may be substantially vertical) to orient the turbine in a desired direction, generally facing the direction of fluid flow.

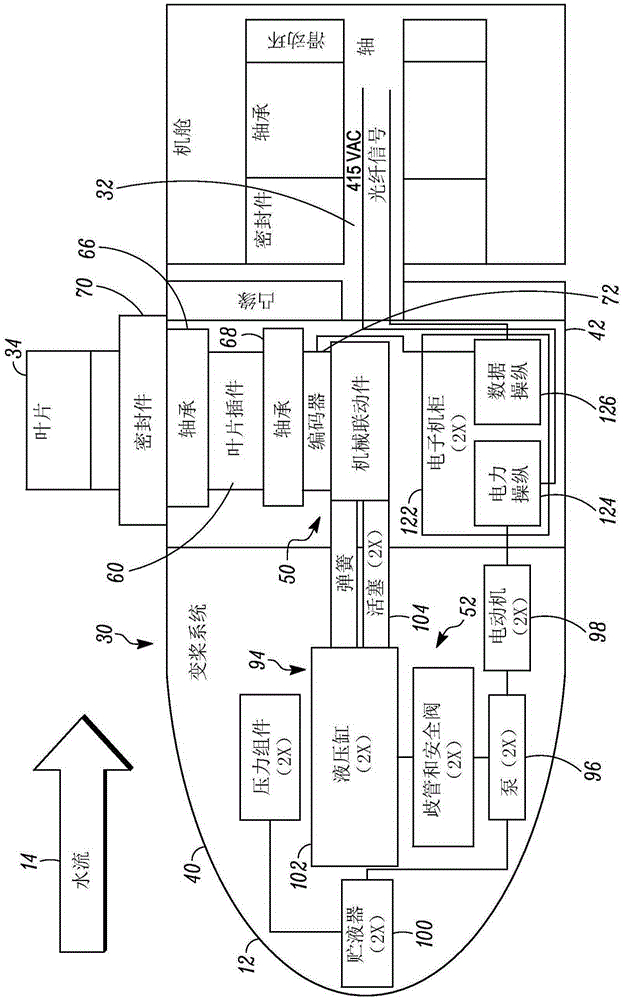

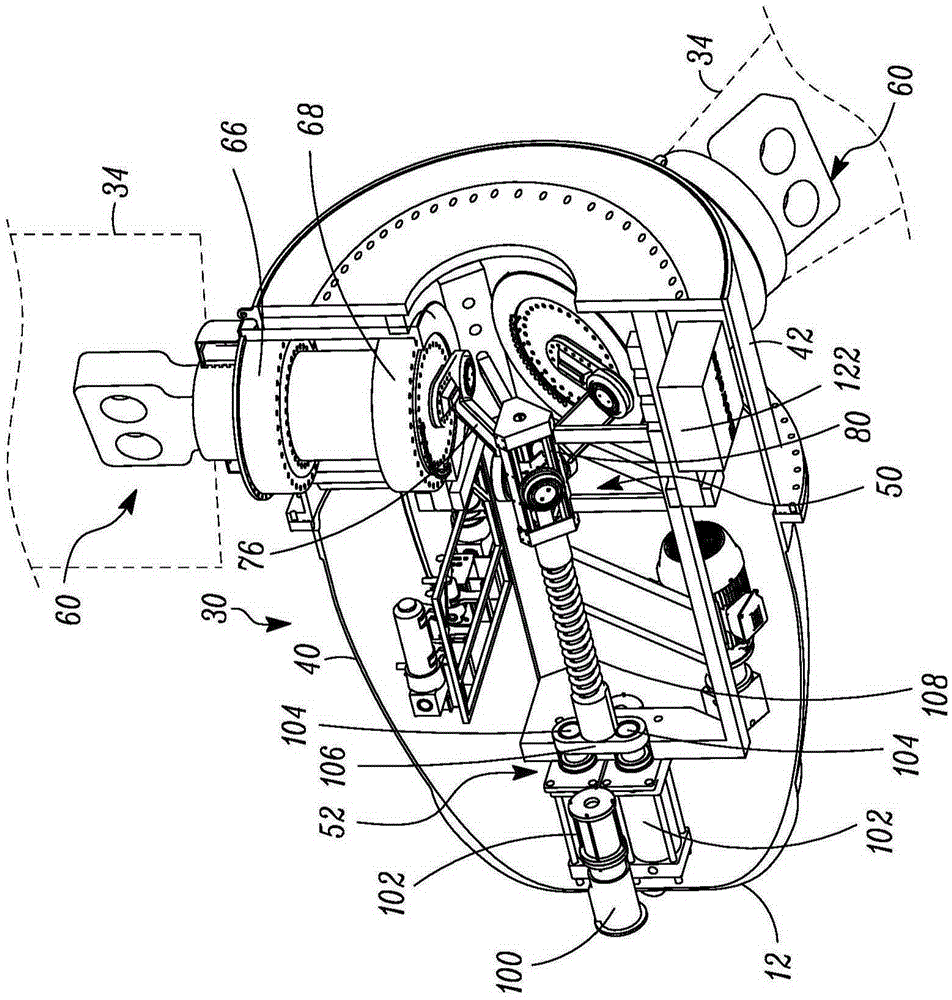

[0021] The turbine 10 includes a bladed rotor portion 30 rotatably arranged in front of the turbine s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com