Individually tailored lingual orthodontic bracket and method for manufacturing same bracket

A manufacturing method and technology of brackets, applied in the direction of brackets, applications, household components, etc., can solve problems such as difficult control of teeth, long distances, errors, etc., and achieve the effect of improving correction efficiency and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

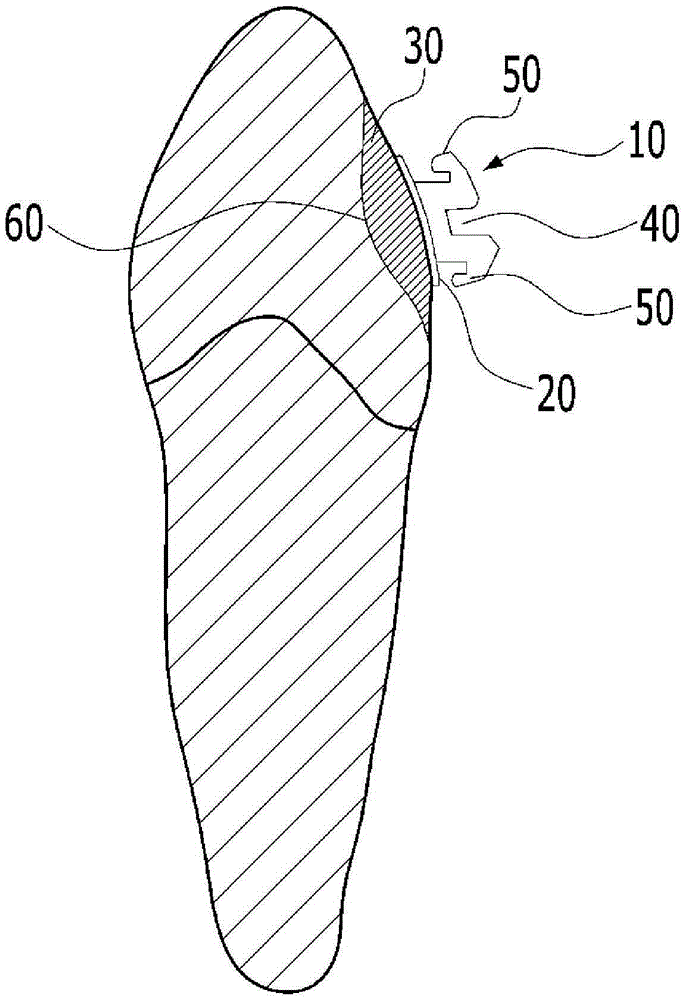

[0022] First, in the present invention, a method for manufacturing a customized bracket for lingual orthodontics will be described separately.

[0023] Therefore, referring to figure 1 , to illustrate the manufacturing method of the custom-made brackets for lingual orthodontic treatment of the present invention, in the manufacturing of the brackets for lingual orthodontic treatment, it is manufactured by the following steps: In the first step 100, the malocclusion reproduced from the patient Cut out each tooth in the model to make a tooth row model rearranged on the ideal position; the second step 200, copy the tooth row model; the third step 300, after performing the pin operation on the copied tooth row model , on each tooth, expand the bottom plate of the bracket with resin in a manner suitable for the tooth surface of each tooth; the fourth step 400, make the bracket on the bottom plate expanded with resin; the fifth step 500, in Forming an injection channel in the resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com