Radiation protective control method for repairing damaged spent fuel assembly of mega-kilowatt nuclear power plant

A radiation protection and control method technology, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve problems such as air pollution to other environments, accidental breakage, pollution, etc., and achieve the effect of reducing radiation risk and preventing accidental release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

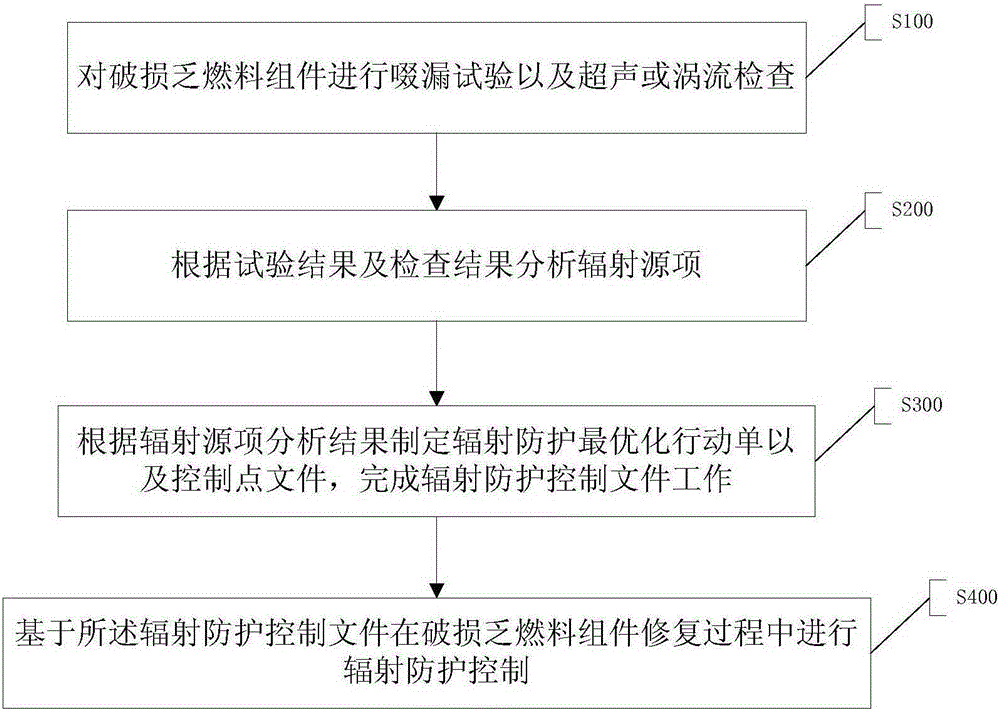

[0036] see figure 1 , a radiation protection control method for repairing damaged spent fuel components of a million-kilowatt nuclear power plant proposed in Embodiment 1, which mainly includes the following steps S100 to S400:

[0037] S100, performing a leak test and ultrasonic or eddy current inspection on the damaged spent fuel assembly.

[0038] In the step S100, the leak test on the damaged spent fuel assembly includes online or offline leak test, which can determine whether the fuel rods in the spent fuel assembly are damaged and roughly locate the damaged position, and the ultrasonic or eddy current inspection can be used for The location of the damage can be precisely located, and the degree of damage such as the size of the breach can be determined.

[0039] S200. Analyze the radiation source item according to the test result and the inspection result.

[0040] In step S100 , the amount of the radiation source item can be estimated by performing a sip test and ultr...

Embodiment 2

[0047] Please continue to combine figure 1The difference between the radiation protection control method for repairing damaged spent fuel components of a mega-kilowatt nuclear power plant proposed in Embodiment 2 and Embodiment 1 is only that each step from Step S100 to Step S400 in Embodiment 1 is further specified, and closer to current practice.

[0048] Step S100 specifically includes: S110, according to the on-line or off-line sip test and ultrasonic or eddy current inspection on the damaged spent fuel assembly, locate the damaged fuel rod and the damaged position, and determine the degree of damage.

[0049] The step S200 specifically includes: S210, analyzing which radiation source items exist in the damaged spent fuel group, and estimating the amount of each radiation source item based on the damage location and damage degree.

[0050] Further, the step S200 may further include: S220, evaluating the impact of the radiation source items on the workers and the environme...

Embodiment 3

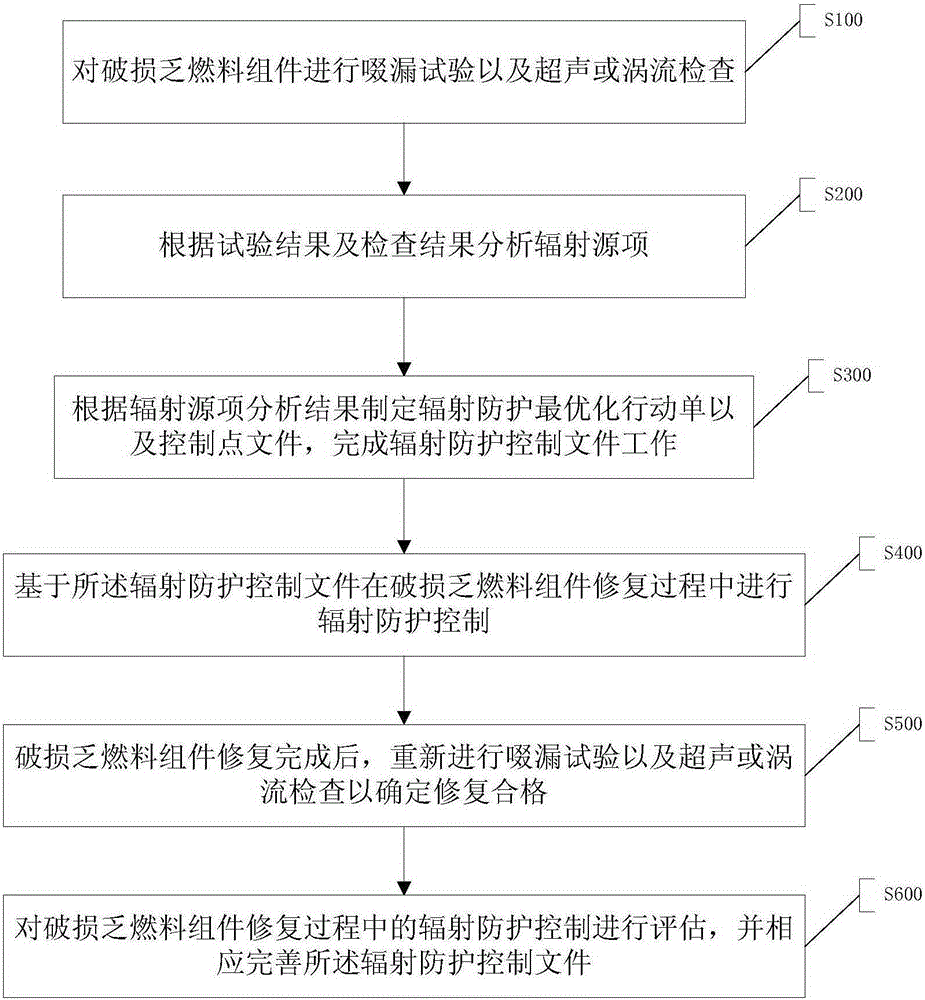

[0059] see figure 2 The radiation protection control method for the repair of damaged spent fuel components of a mega-kilowatt nuclear power plant proposed in the third embodiment is based on the first or second embodiment for further optimization and supplementation. Specifically, based on the first embodiment For example, the third embodiment also includes the following steps S500 and S600:

[0060] S500. After the repair of the damaged spent fuel assembly is completed, perform the leak test and ultrasonic or eddy current inspection again to confirm that the repair is qualified.

[0061] During the test and inspection process of step S500, radiation protection should pay special attention to the operation of related equipment after use, and continuous measurement should be carried out to ensure that the radiation level does not exceed the preset value, otherwise the equipment needs to be dropped into the water again and wait for flushing Treatment; after the equipment is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com