Stress corrosion and hydrogen measuring electrochemical in-situ measurement device under slow strain speed condition

A slow strain rate, stress corrosion technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc. It can solve the problems of unadjustable sample shape and temperature control, and achieve simple structure and convenient use. Flexible, accurate readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

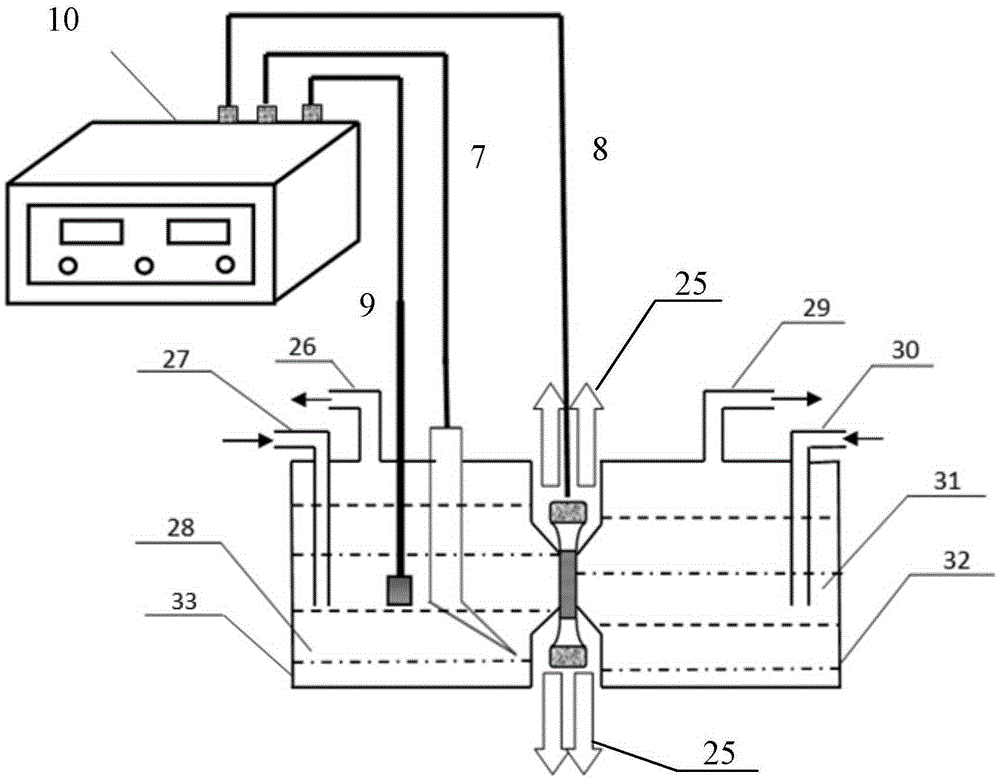

[0017] The electrochemical in-situ measurement device for stress corrosion and hydrogen measurement under the condition of slow strain rate provided by the present invention will be described in detail below with reference to the accompanying drawings and specific examples.

[0018] like figure 1 — Figure 4 As shown, the stress corrosion and hydrogen measuring electrochemical in-situ measurement device under the slow strain rate condition provided by the present invention includes an electrochemical workstation 10, a lower clamp 2, an upper clamp 6, a fixing device 18, an auxiliary electrode 7, a working electrode 8, Reference electrode 9, tensile sample 5, slow strain stretching machine 25, computer, isolation transformer 21, corrosion device and hydrogen measuring device; wherein the corrosion device includes a temperature controller 1, an outlet pipe 3, a corrosion container 4, and a temperature sensor 11. Gas pipeline 14, gas flowmeter 15, gas cylinder 16 and water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com