Net cage model test platform

A model test and platform technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of increasing errors in test results, difficulty in ensuring data reliability, and increasing the large-scale ratio of model cages. and other issues, to achieve the effect of comprehensive and accurate test data, true and reliable test data, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

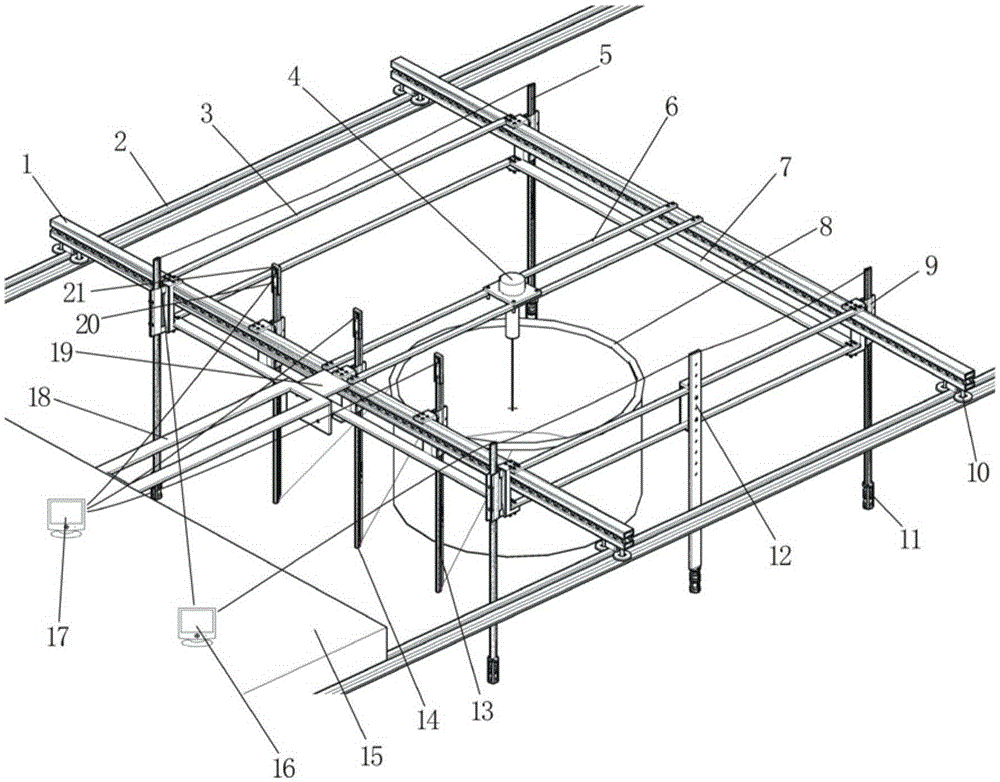

[0014] The design and manufacture of the net cage model test platform is based on the existing still tank trailer system. The size of the frame can be adjusted by referring to the size of the still tank for the application test. The size of the still tank is 6m×90m×3m as an example, that is, the width of the tank 6m, length 90m, depth 3m; Trailer speed range 0-2m / s, track wheel spacing 6.45m The specific implementation of the cage model test platform (see figure 1 — Figure 7 ).

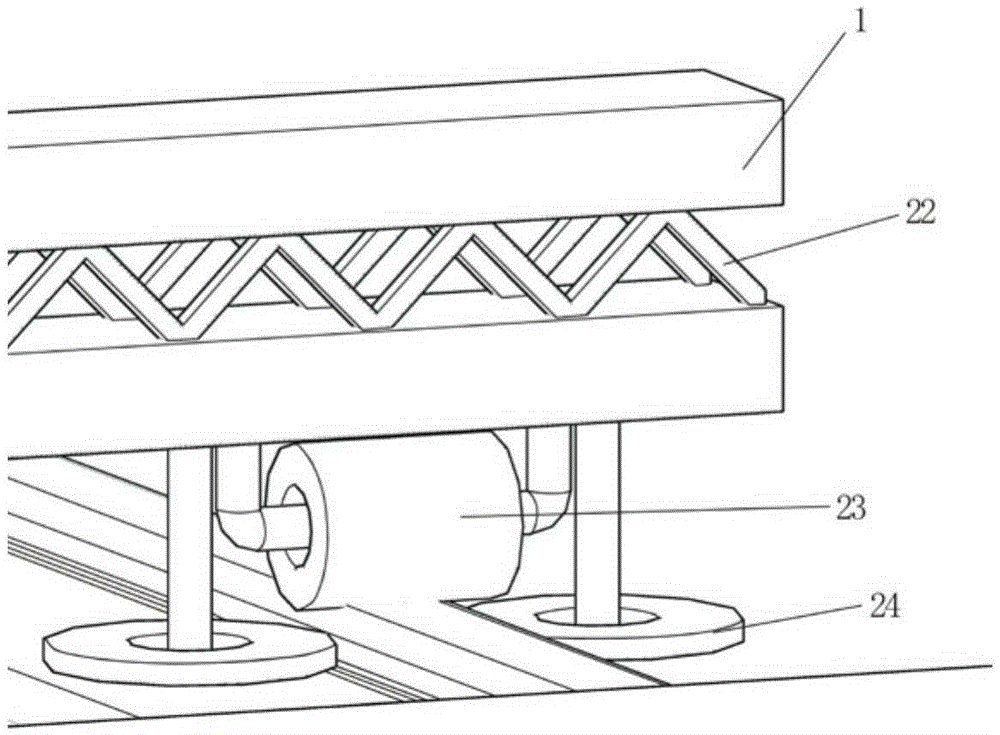

[0015] Platform main beam 1 aluminum alloy square tube is 6.8m in length, the specification of a single square tube can be selected according to this span (6.8m) and can bear more than 100kg, and two aluminum alloy square tubes are welded between two aluminum alloy square tubes to form an M-shaped connection support 22 to form a Main beam, there are 2 main beams on the platform, and the load-bearing capacity of each main beam is ≥200kg.

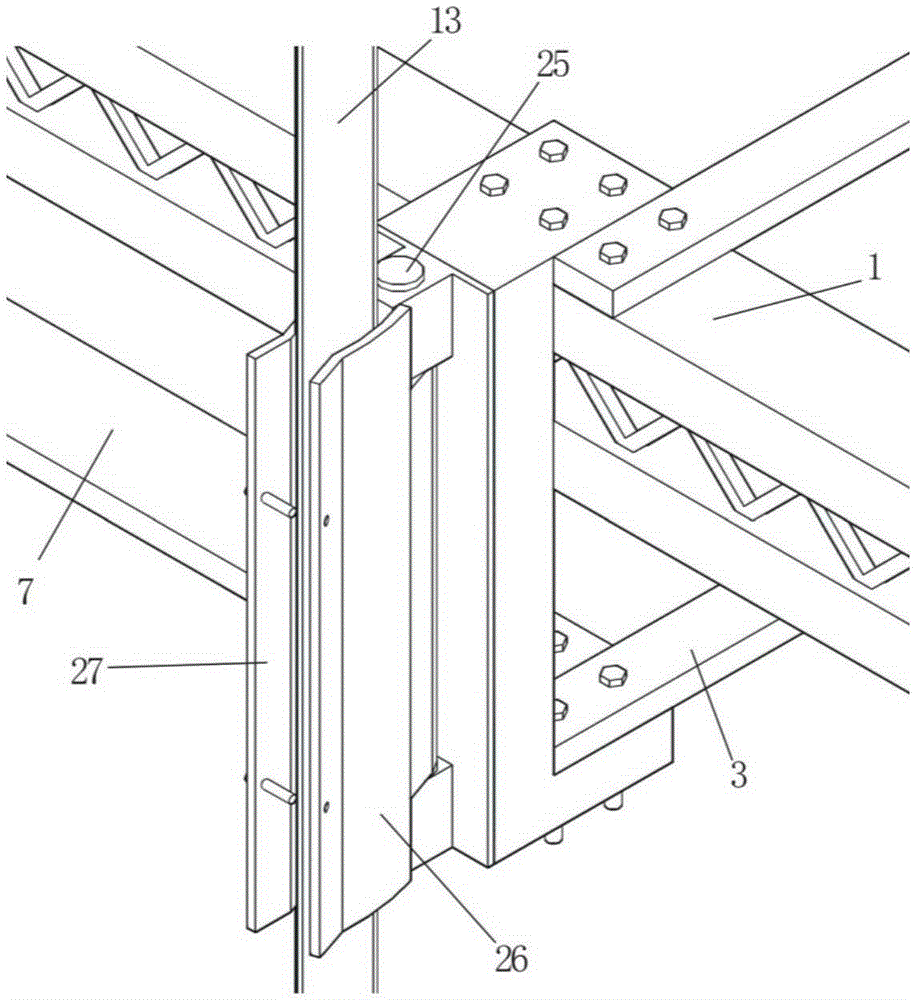

[0016] The longitudinal connecting rod 3 is made of an alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com