Size range measuring tool of stepped shaft part and measuring method

A technology of size range and stepped shaft, which is applied in the field of measuring and measuring tools for the size range of stepped shaft parts, can solve the problems such as the inability to measure and reduce the size of the ruler and gauge, and achieve the effect of eliminating hidden quality risks, reducing labor costs and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with embodiment.

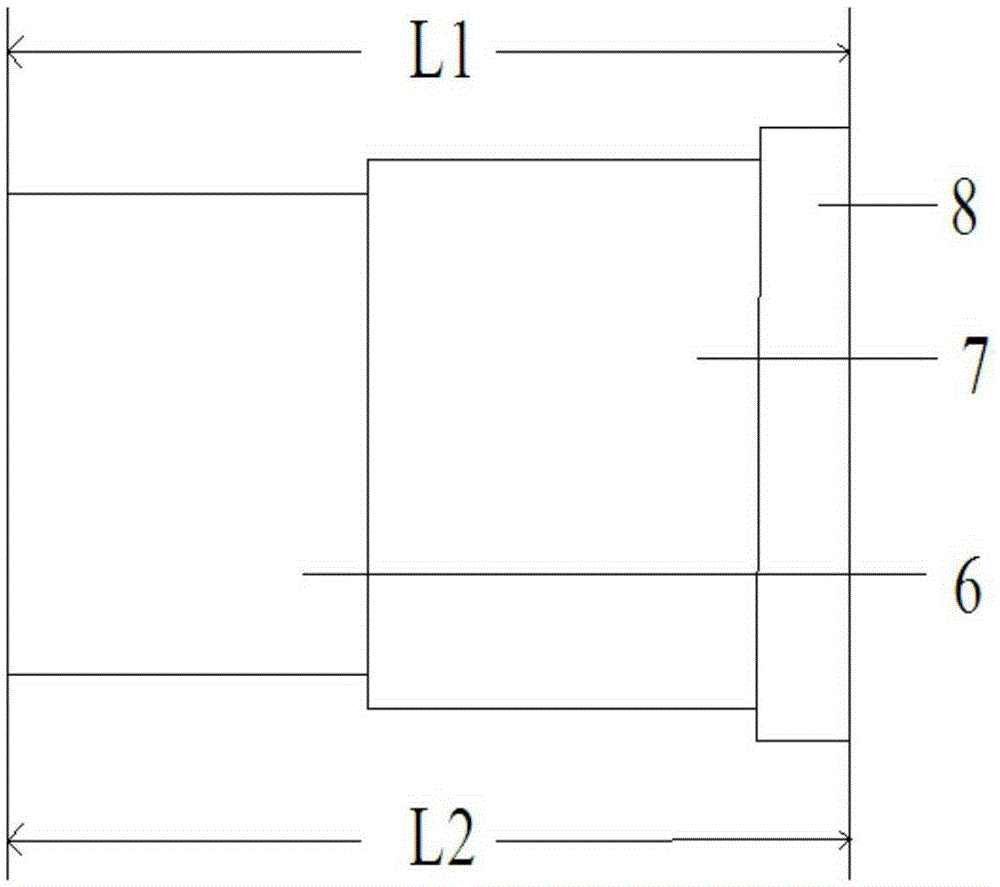

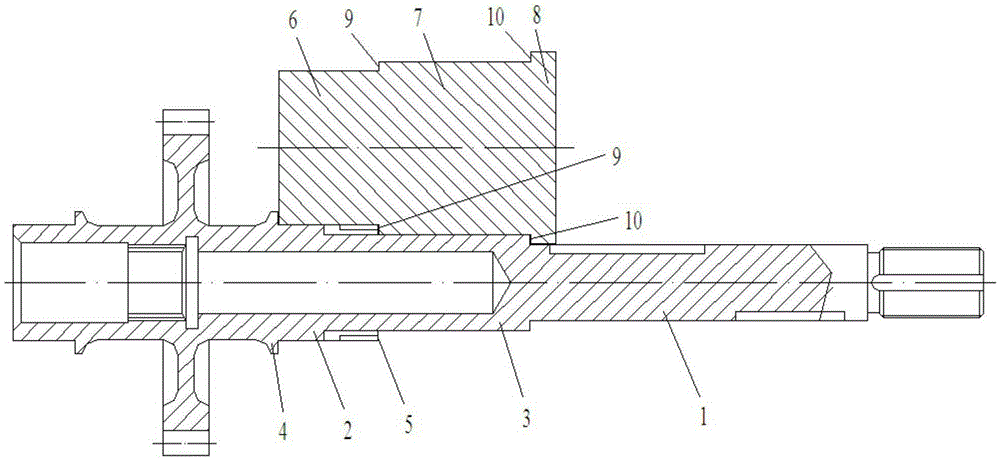

[0028] Such as Figure 1 ~ Figure 2 As shown, a measuring tool for measuring the size range of a stepped shaft part is used to measure the axial dimension of the stepped part of the stepped shaft part. The part 1 at least includes a first section shaft 2 and a second section shaft 3. A shaft shoulder 4 is provided at the end of the shaft 2, a first step 5 is provided between the first section of the shaft 2 and the second section of the shaft 3, and the measuring tool includes a first measuring part 6, a second measuring part 7 and a third measuring part Part 8, the total axial length L of the second measuring part 7 and the first measuring part 6 1 The maximum tolerance value of the length of the step to be measured is reduced by 0.01mm, and the total axial length of the other side is L 2 Then the minimum tolerance value of the length of the step to be measured is increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com