Outer fire cover of burner

A technology of an outer ring fire cover and a burner, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of flameout, main flame flying fire phenomenon, unsatisfactory effect of flame stabilization method, etc., and achieves enhanced stability. , Improve thermal efficiency and ensure the effect of success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

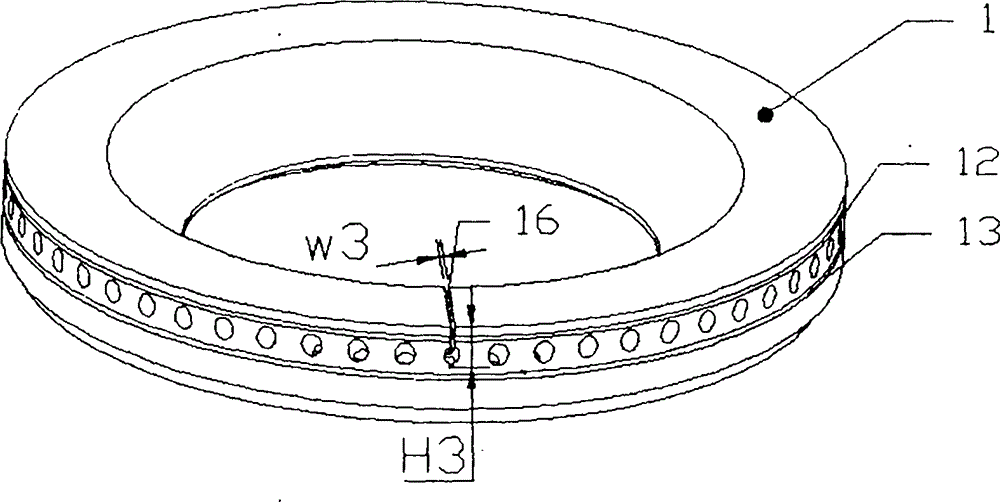

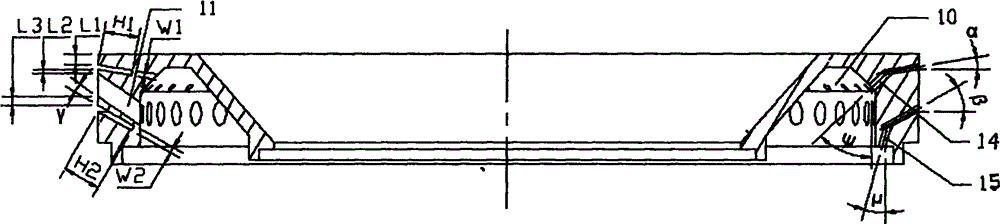

[0017] An embodiment of a burner outer ring fire cover of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0018] The burner outer ring fire cover according to the present invention, the outer ring fire cover can be disassembled and positioned on the burner head or the burner head seat, the outer ring fire cover includes a cylindrical fire cover body 1, the The bottom of the fire cover body 1 is provided with a through hole to form a gas mixing chamber 10, and the lower end surface of the gas mixing chamber 10 communicates with the gas supply groove on the burner or burner seat; The circumferential direction of 1 is provided with several main fire holes 11 at intervals, and one end of the several main fire holes 11 is connected with the air-mixing chamber 10, and the other ends of the several main fire holes 11 are all opened in the said On the outer vertical surface of the fire cover body 1; in addition, on the said fire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Section width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com