Slurry balance shield machine with freezing function

A mud-water balance, shield machine technology, applied in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of difficult construction, high cost, sand influx, etc., to reduce construction difficulty, save man-hours, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the figures.

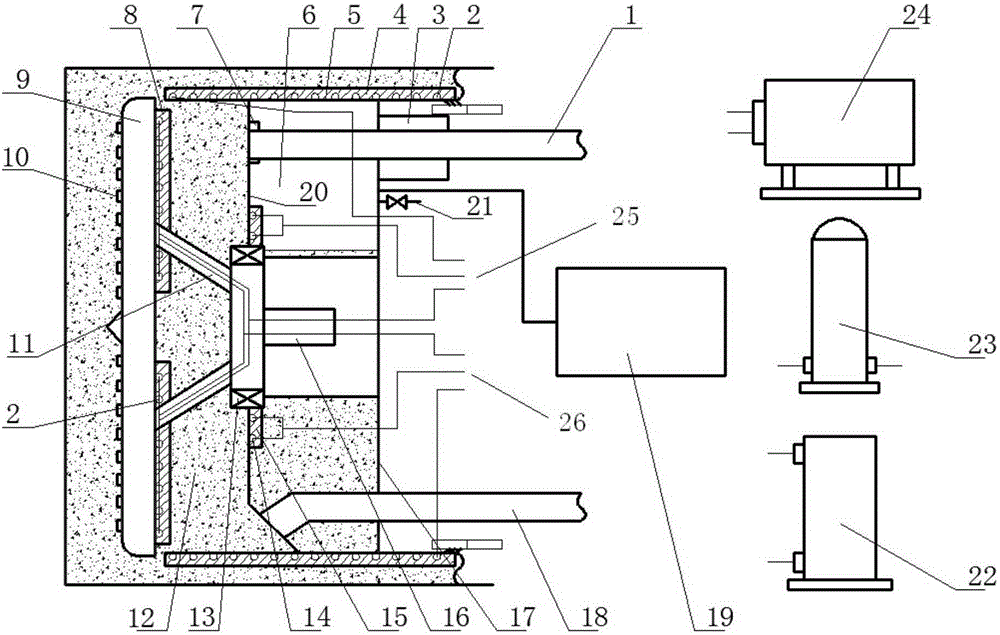

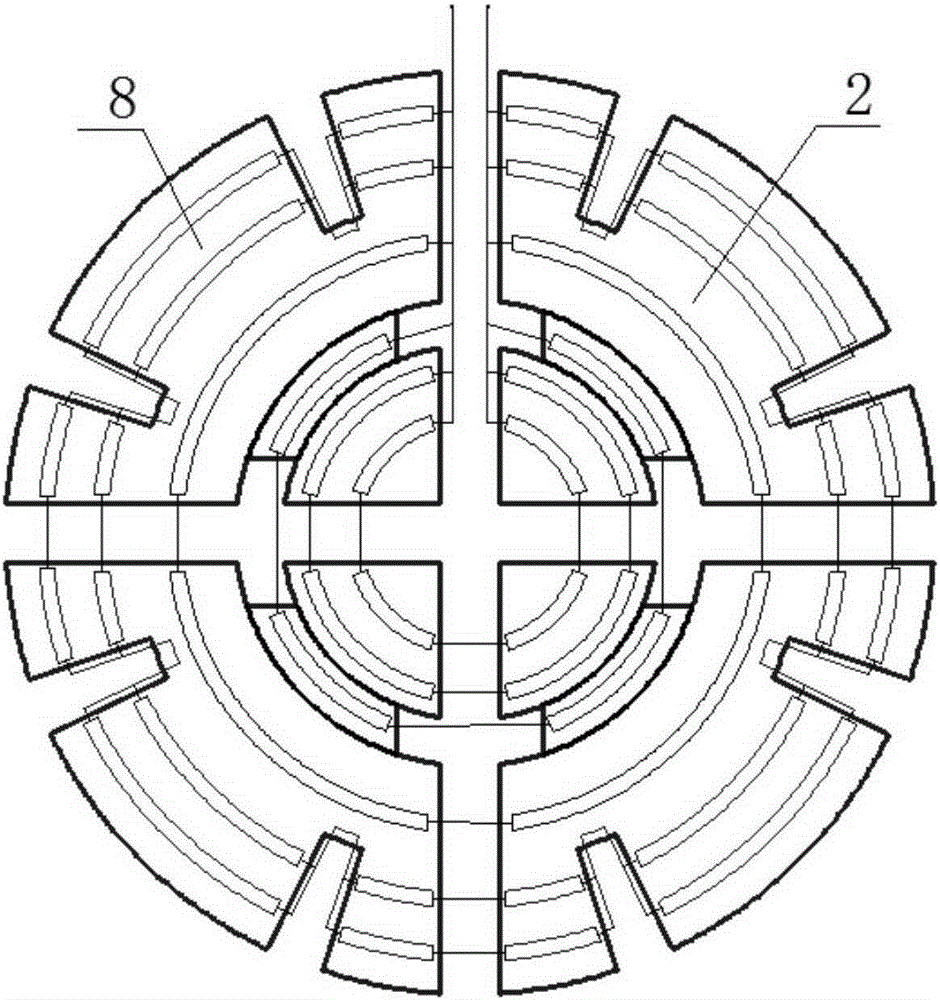

[0027] see figure 1 , figure 2 , image 3 and Figure 4 , mud-water balance shield machine with freezing function, including slurry inlet pipe 1, shield body 5, man cabin 3, cutterhead 9, cutter 10, cutterhead support arm 11, muddy water tank 12, main drive unit 13, air cushion chamber 6 , air compressor 19, air control valve 21, rear bulkhead 17, slurry discharge pipe 18 and front bulkhead 20, front cabin door 7 and heating pipeline 14 are installed on the front bulkhead 20, on cutter head 9 and shield body 5 is arranged with a freezing circulation pipeline 2; includes a heating pipeline 14 for heating the main drive unit 13; also includes a heating device 22, a storage tank 23 and a refrigeration unit 24, and the freezing circulation pipeline 2 passes through a liquid inlet pipe 25, a return The liquid pipe 26 and the central rotary joint 16 are connected with the refrigerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com