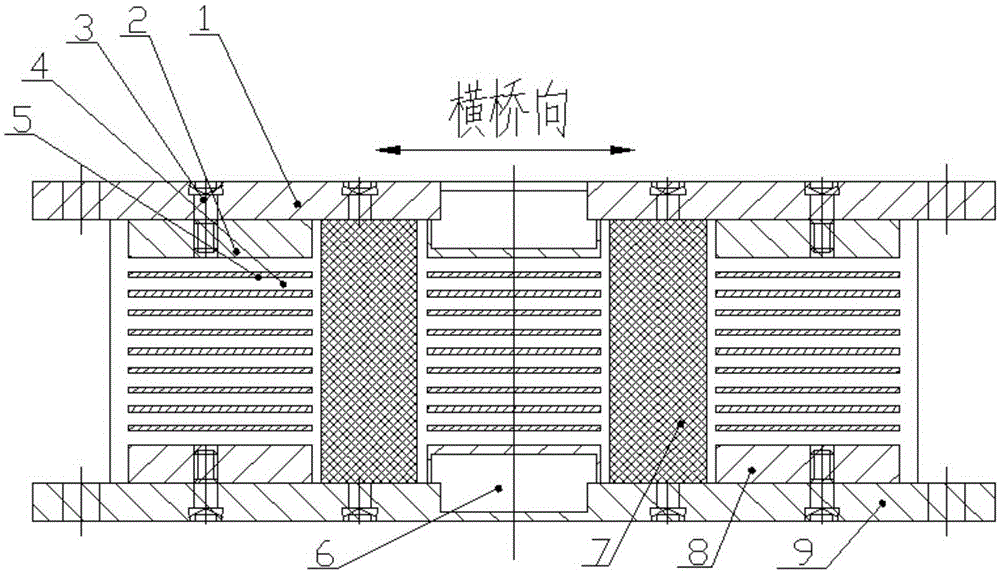

High-performance rubber composite for bridge damping support and preparation method thereof

A technology of shock-absorbing bearings and composite materials, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of elasticity and flexibility that cannot meet the ideal requirements, and low damping ratio, so as to achieve good comprehensive shock-absorbing effect and improve damping performance , The effect of widening the damping temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

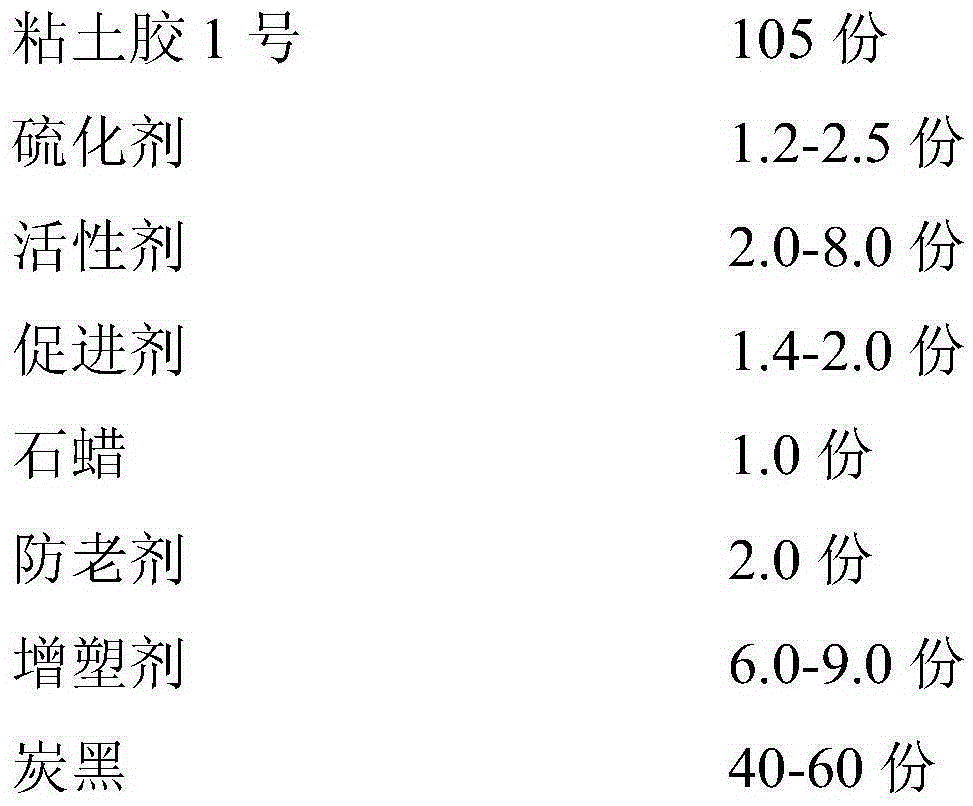

[0024] Laminated rubber (clay glue No. 1 contains 100 parts of natural rubber and 5 parts of organic clay) composite materials were prepared according to Table 1. Concrete preparation process is as follows:

[0025] Laminated rubber preparation process - Weigh 105 parts of clay glue No. 1 and masticate 7 times on the open mill (roller distance 0.5mm); control the roll temperature (roller temperature <40°C), and add 5 parts of activator zinc oxide and 2 parts of stearic acid, 1 part of paraffin, 2 parts of antioxidant 4010NA, 1.2 parts of sulfur, 40 parts of carbon black N330, 3 parts of Si69, 6 parts of aromatic oil, 1.4 parts of N-cyclohexyl-2-benzothiazole sulfen Amide (abbreviation: promote CZ), cutter and bagging until mixed evenly; adjust the roller distance to the next film, park for 8h, and set aside. Cut the mixed rubber into a film with a specification of 295×415×7mm, and then stack it in sequence according to the order of one steel plate and one film. Put the bille...

Embodiment 2

[0030] Laminated rubber preparation process - Weigh 105 parts of clay glue No. 1 and masticate 7 times on the open mill (roller distance 0.5mm); control the roll temperature (roller temperature <40°C), and add 5 parts of activator zinc oxide and 2 parts of stearic acid, 1 part of paraffin, 2 parts of anti-aging agent 4010NA, 1.2 parts of sulfur, 40 parts of carbon black N330, 3 parts of Si69, 6 parts of aromatic oil, 1.4 parts of CZ, cutting knife and bagging until mixed evenly; Adjust the roller distance to the next film, park it for 8 hours, and wait for use. Cut the mixed rubber into a film with a specification of 295×415×7mm, and then stack it in sequence according to the order of one steel plate and one film. Put the billet into the preheated mold, the mold temperature is 145°C, vulcanize under the pressure of 15Mpa for 2 hours, and the rubber bearing is made.

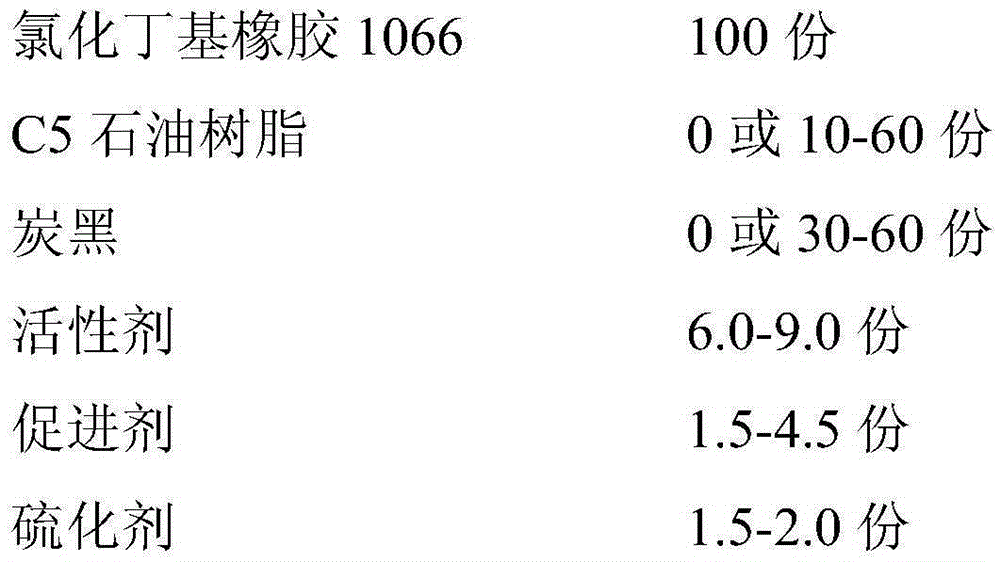

[0031] Preparation process of rubber core material composite material - masticate 100 parts of chlorinated but...

Embodiment 3

[0035]Laminated rubber preparation process - Weigh 105 parts of clay glue No. 1 and masticate 7 times on the open mill (roller distance 0.5mm); control the roll temperature (roller temperature <40°C), and add 5 parts of activator zinc oxide and 1 part of stearic acid, 1 part of paraffin, 2 parts of anti-aging agent 4010NA, 1.2 parts of sulfur, 50 parts of carbon black N330, 3 parts of Si69, 6 parts of aromatic hydrocarbon oil, 1.4 parts of CZ, cut and pack until mixed evenly; Adjust the roller distance to the next film, park it for 8 hours, and wait for use. Cut the mixed rubber into a film with a specification of 295×415×7mm, and then stack it in sequence according to the order of one steel plate and one film. Put the billet into the preheated mold, the mold temperature is 145°C, vulcanize under the pressure of 15Mpa for 2 hours, and the rubber bearing is made.

[0036] Preparation process of rubber core material composite material - masticate 100 parts of chlorinated butyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com