Regeneration method of waste active carbon for monosodium glutamate by supersonic wave and spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The method for ultrasonic spraying to regenerate activated carbon for waste monosodium glutamate, the specific steps are as follows: 10g of activated carbon for waste monosodium glutamate is dried at a temperature of 105±0.5°C for 1.5h, cooled to room temperature and placed in a microwave oven with a stirrer (controlled stirring The speed is 160rpm), when the temperature rises to 700°C, turn on the ultrasonic spray device and adjust the flow rate of water mist at room temperature to 1ml / min, turn off the microwave oven after 10 minutes, and pass in nitrogen gas (the flow rate of nitrogen gas is 200ml / min) until it cools down to room temperature , to obtain activated carbon for regeneration of waste monosodium glutamate.

[0021] The methylene blue value of the activated carbon for regenerating waste monosodium glutamate obtained through the above steps is 169.5 mg / g, and the regeneration yield is 65.36%.

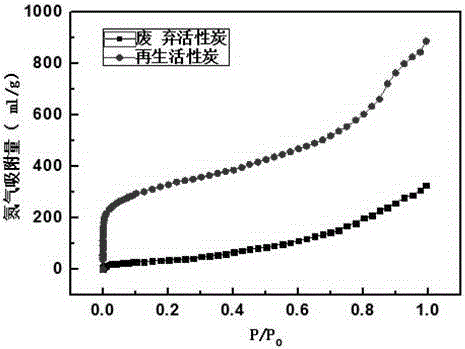

[0022] The adsorption isotherms at 77K of the activated carbon f...

Embodiment 2

[0024] The method for the ultrasonic spray regeneration of waste monosodium glutamate activated carbon, its specific steps are as follows: 10g of waste monosodium glutamate with activated carbon (the specific surface area of waste monosodium glutamate with activated carbon is 318.2m 2 / g, the value of methylene blue is 30mg / g) at a temperature of 105±0.5°C for 1.5h, cooled to room temperature and placed in a microwave oven with a stirrer (control the stirring speed at 180rpm), when the temperature rises to 750°C Turn on the ultrasonic spray device and adjust the flow rate of water mist at room temperature to 1.5ml / min, turn off the microwave oven after 15 minutes, and pass in nitrogen gas (the flow rate of nitrogen gas is 350ml / min) until it cools to room temperature to obtain activated carbon for recycling waste monosodium glutamate.

[0025] The methylene blue value of the activated carbon for regenerating waste monosodium glutamate obtained through the above steps is 174mg...

Embodiment 3

[0027] The method for the ultrasonic spray regeneration of waste monosodium glutamate activated carbon, its specific steps are as follows: 10g of waste monosodium glutamate with activated carbon (the specific surface area of waste monosodium glutamate with activated carbon is 318.2m 2 / g, methylene blue value is 45mg / g) at a temperature of 105±0.5°C for 1.5h, cooled to room temperature and placed in a microwave oven with a stirrer (control the stirring speed at 210rpm), when the temperature rises to 800°C Turn on the ultrasonic spray device and adjust the flow rate of water mist at room temperature to 2ml / min, turn off the microwave oven after 10 minutes, and pass in nitrogen gas (the flow rate of nitrogen gas is 400ml / min) until it cools to room temperature to obtain activated carbon for recycling waste monosodium glutamate.

[0028] The methylene blue value of the activated carbon for regenerating waste monosodium glutamate obtained through the above steps is 184.5 mg / g, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com