MEMS device for preventing suspension layer etching damage

A technology for suspended layers and devices, applied in the direction of electric solid devices, semiconductor devices, piezoelectric devices/electrostrictive devices, etc., can solve problems such as damage to the bottom of the movable structure layer, avoid etching backsplash damage, and ensure integrity The effect of sex, the realization method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 13 As shown, a MEMS device for preventing etching damage of the suspension layer provided by the present invention is composed of an SOI silicon wafer substrate, a movable structure layer 8 and a cap silicon wafer 10,

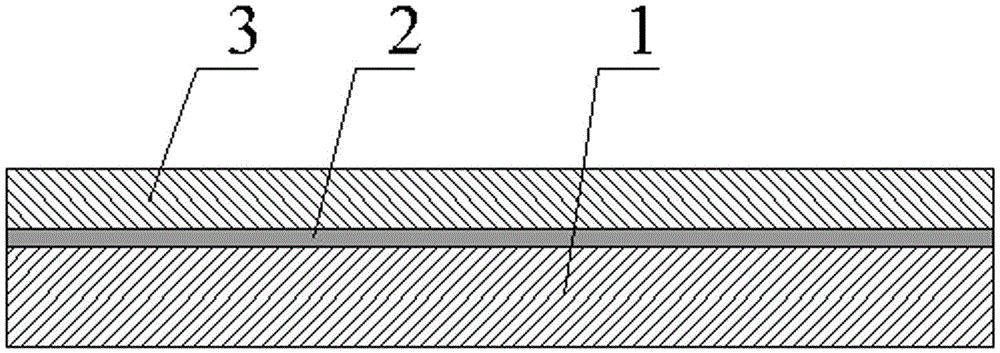

[0026] The substrate is made of SOI silicon wafer (composed of substrate silicon 1, buried oxide layer 2 and top layer silicon 3), and the top layer silicon 3 of the SOI silicon wafer is made of N-type or P-type low-resistance silicon with a resistivity of 0.001Ω cm-0.5Ω cm;

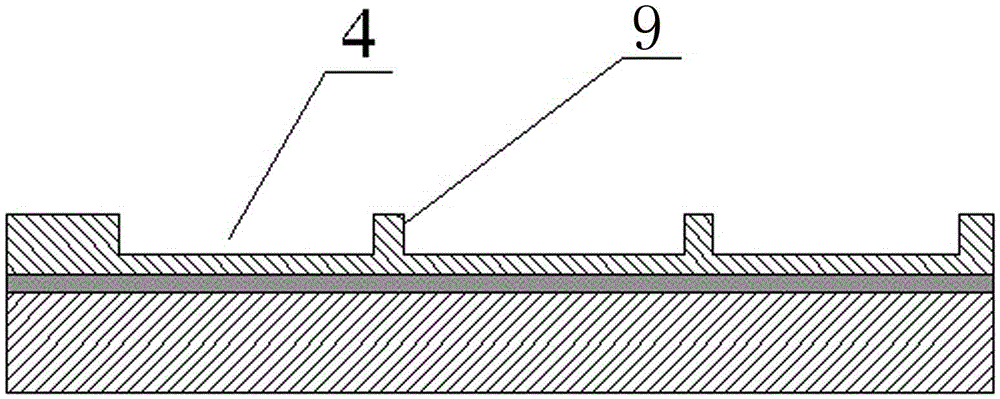

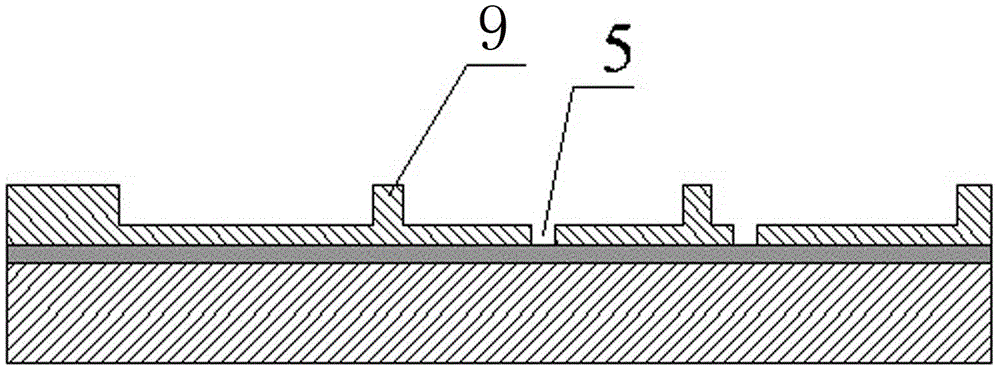

[0027] A shallow cavity 4, an electrode 9 (also called a lower electrode) and an electrode isolation groove 5 are provided on the surface of the top layer silicon 3 of the SOI silicon wafer of the substrate, and a first oxide layer 6 and a second oxide layer 7 are provided on the surface of the shallow cavity 4. The thickness of the first oxide layer 6 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com