Multi-section air bag type inflatable sleeve tandem jointing inflation shaft

A technology of an inflatable sleeve and an inflatable shaft is applied in the field of airbag-type inflatable shafts, which can solve the problems of unenvironmental protection, waste of materials, and easy damage of long airbags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

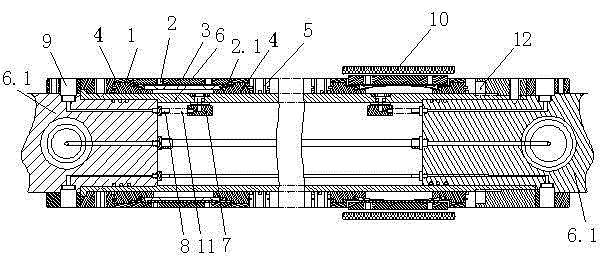

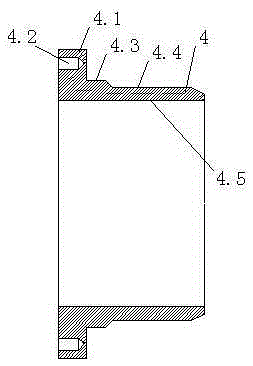

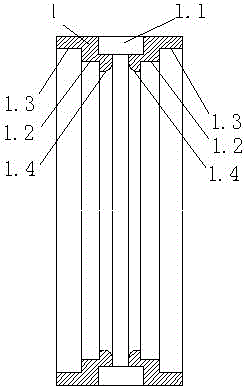

[0019] like Figure 1 to Figure 8 , the present invention relates to a multi-segment airbag-type air inflation sleeve spliced in series, including an air expansion sleeve shell 1, a plurality of expansion block assemblies 2, an airbag 3 with expansion and contraction functions, left and right end covers 4, gaskets 5, The main shaft 6, the intake and exhaust assembly 7, the two ends of the airbag 3 are respectively provided with radial limit protrusions 3.1, and the limit protrusions 3.1 are located in the first limit stops 1.2 at both ends of the air expansion sleeve shell 1 , the axial parts of the two ends of the outer wall of the airbag 3 are tightly contacted with the inner peripheral surface 1.4 of the air expansion sleeve shell 1, and the outer circumference of one end of the left and right end caps 4 is provided with a limiting shoulder 4.1, and the first shoulder of the left and right end caps 4 4.3 are tightly pressed against the two ends of the inner wall of the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com