Laser processsing system for processing workpiece with laser

A technology for laser processing and processed objects, which is applied in general control systems, laser welding equipment, metal processing equipment, etc., and can solve problems such as missed removal or correction of quality, product deformation, and step difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the following drawings, the same reference numerals are assigned to the same components. For easy understanding, the scales of these drawings are appropriately changed.

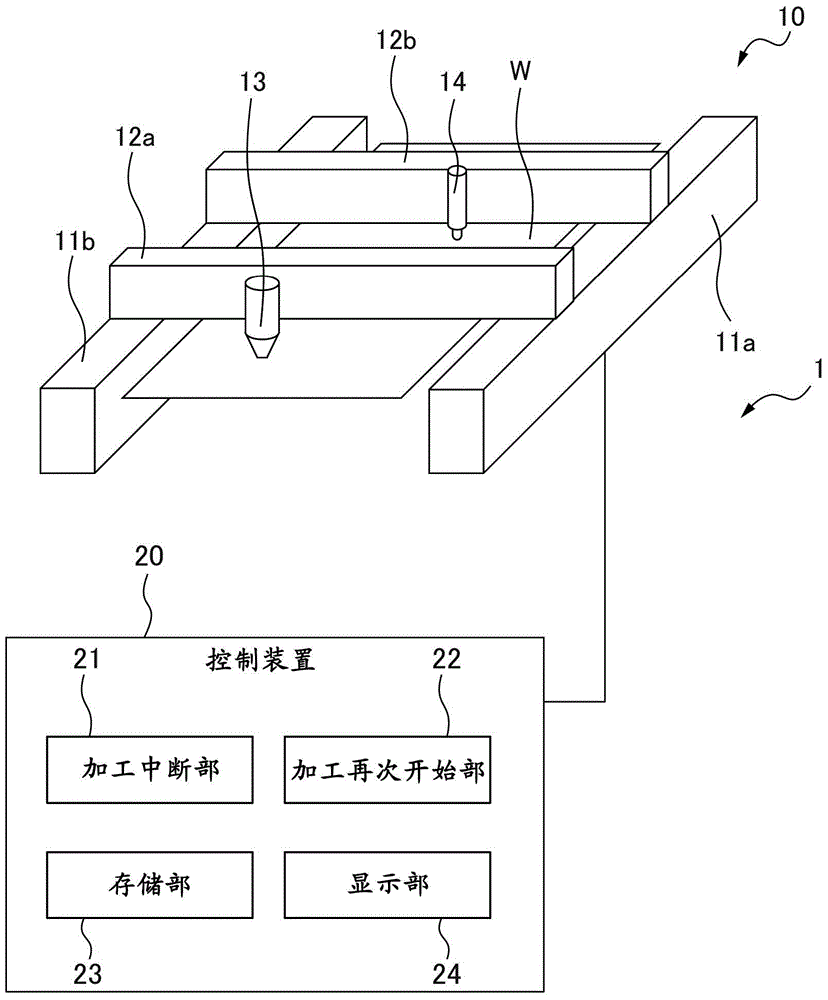

[0034] figure 1 It is a schematic diagram of the laser processing system based on 1st Embodiment of this invention. Such as figure 1 As shown, the laser processing system 1 mainly includes a laser processing machine 10 and a control device 20 for controlling the laser processing machine 10 . figure 1 The illustrated laser processing machine 10 is, for example, a laser cutting device. The laser processing machine 10 has two guide rails 11a, 11b parallel to each other, and a plate-shaped workpiece W is arranged between these guide rails 11a, 11b.

[0035] And, the positioning rails 12a, 12b perpendicular to the guide rails 11a, 11b are disposed above the guide rails 11a, 11b. The length of these p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com