Vacuum spray-freezing granulation device and method thereof

A technology of freezing granulation and vacuum spraying, which is applied in the direction of refrigeration and liquefaction, refrigerators, refrigeration components, etc. It can solve the problems of material pollution, high energy consumption, and waste, so as to prevent material contamination, increase freezing rate, and reduce production. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

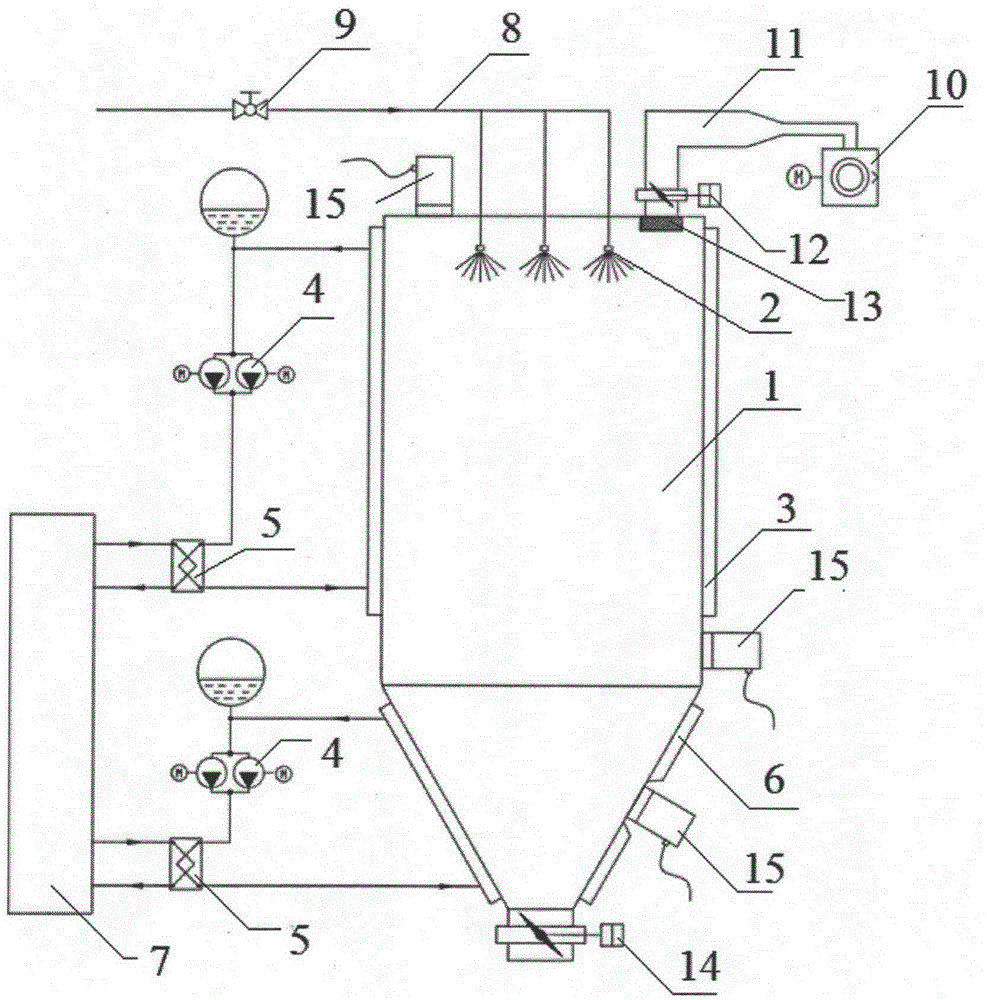

[0041] Such as figure 1 As shown, it is a schematic structural diagram of the vacuum spray freezing granulation device in Example 1, and the vacuum spray freezing granulation device includes containers 1 for accommodating products during the vacuum spray freezing granulation process; The freeze-dried liquid is atomized and dispersed into droplets and sprayed into the atomization nozzle 2 in the container 1; it is used to form a vacuum environment in the container 1 so that part of the components in the droplets are vaporized in the vacuum environment A vacuum system that absorbs heat and then cools down and freezes the liquid droplets to form particles; and a condensing device for condensing part of the components in the vaporized liquid droplets. The atomizing nozzle 2 is arranged in the container 1 . The vacuum system is connected with the container 1 .

[0042] The container 1 is an airtight container with a cylindrical upper part and a conical lower part, which can condu...

Embodiment 2

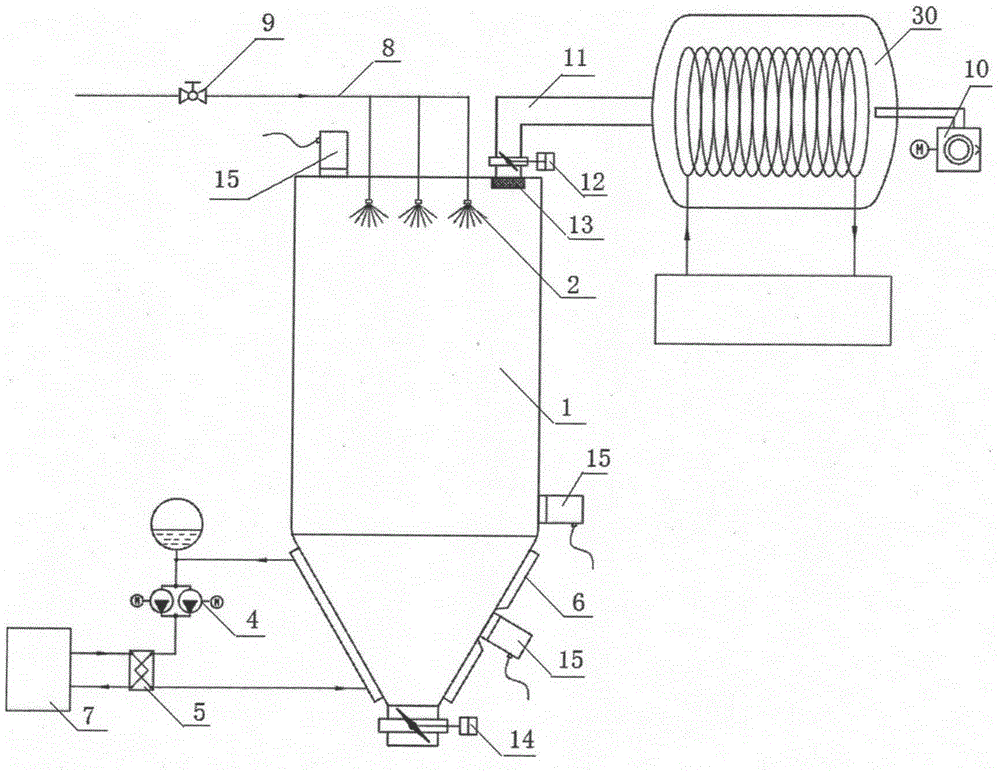

[0047] Such as figure 2 As shown, it is a schematic structural diagram of the vacuum spray freezing granulation device in Example 2. The vacuum spray freezing granulation device is similar to Example 1, the difference is that the condensing device is located outside the container 1 And the condenser 30 that is connected with the described container 1, described condenser 30 connects the connection port of described container 1 through pipeline 11, and described vacuum pump 10 connects condenser 30 through another pipeline, and described condensing A valve 12 is provided on the pipeline 11 between the device 30 and the connection port of the container 1, and the first refrigeration jacket 3 is not provided outside the upper part of the container 1.

[0048] Take the ivy powder aqueous solution obtained by dissolving 125g of ivy powder in 2L of water as an example. When in use, control the temperature of the silicone oil in the second refrigeration jacket 6 to be -20°C, and fir...

Embodiment 3

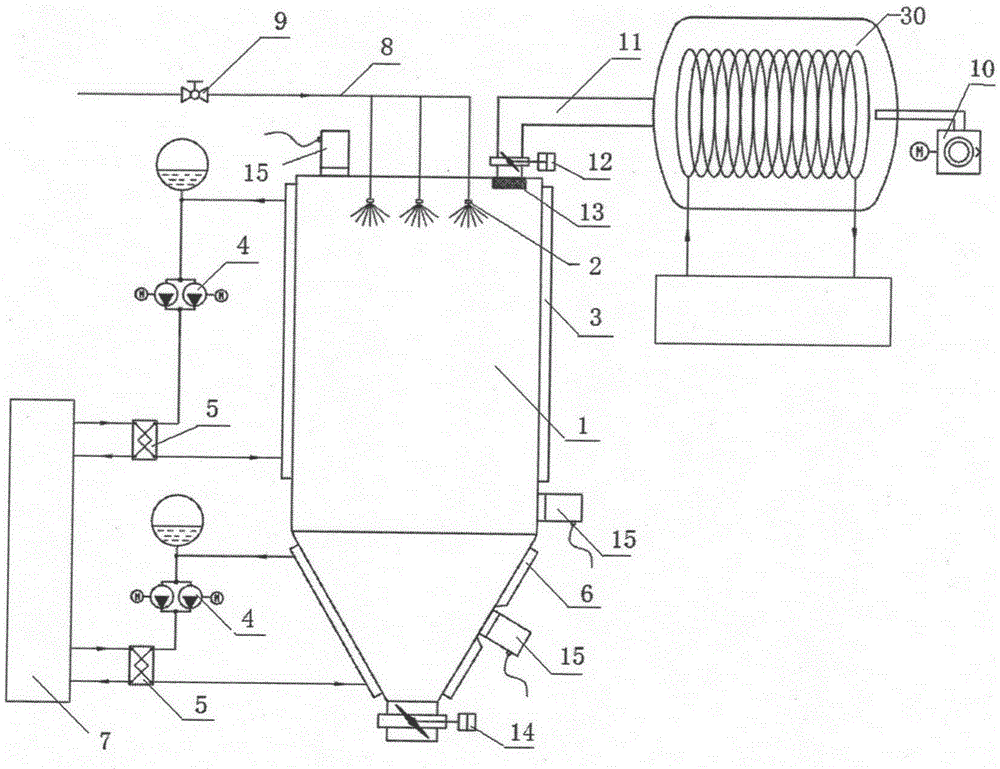

[0050] Such as image 3 As shown, it is a schematic structural diagram of the vacuum spray freezing granulation device in Example 3. The vacuum spray freezing granulation device is similar to Example 1, the difference is that the condensing device is the first refrigeration jacket 3 and the condensing The combination in the container 30, the first refrigeration jacket 3 is arranged on the outside of the upper part of the container 1, the condenser 30 is arranged outside the container 1, and the condenser 30 passes through the pipeline 11 The connection port of the container 1 is connected, the vacuum pump 10 is connected to the condenser 30 through another pipeline, and a valve 12 is provided on the pipeline 11 between the condenser 30 and the connection port of the container 1 .

[0051] Take the ivy powder aqueous solution obtained by dissolving 125g of ivy powder in 2L of water as an example. When in use, control the temperature of the silicone oil in the first refrigeratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com