Fully automatic shell opening machine for cashew nuts

A fully automatic cashew nut technology, applied in shelling, pod removal, food science, etc., can solve the problems of high cost, complex structure, inconvenient maintenance, etc., and achieve the effect of low cost, simple structure, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

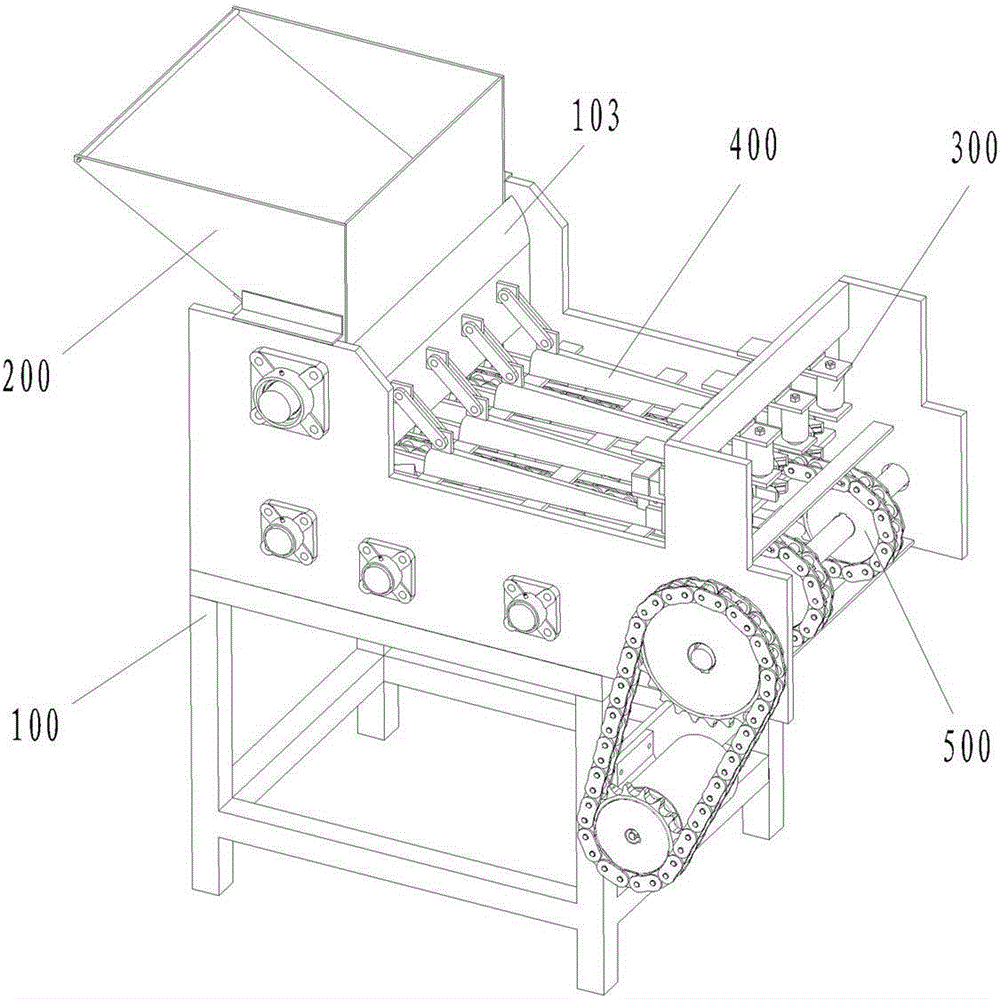

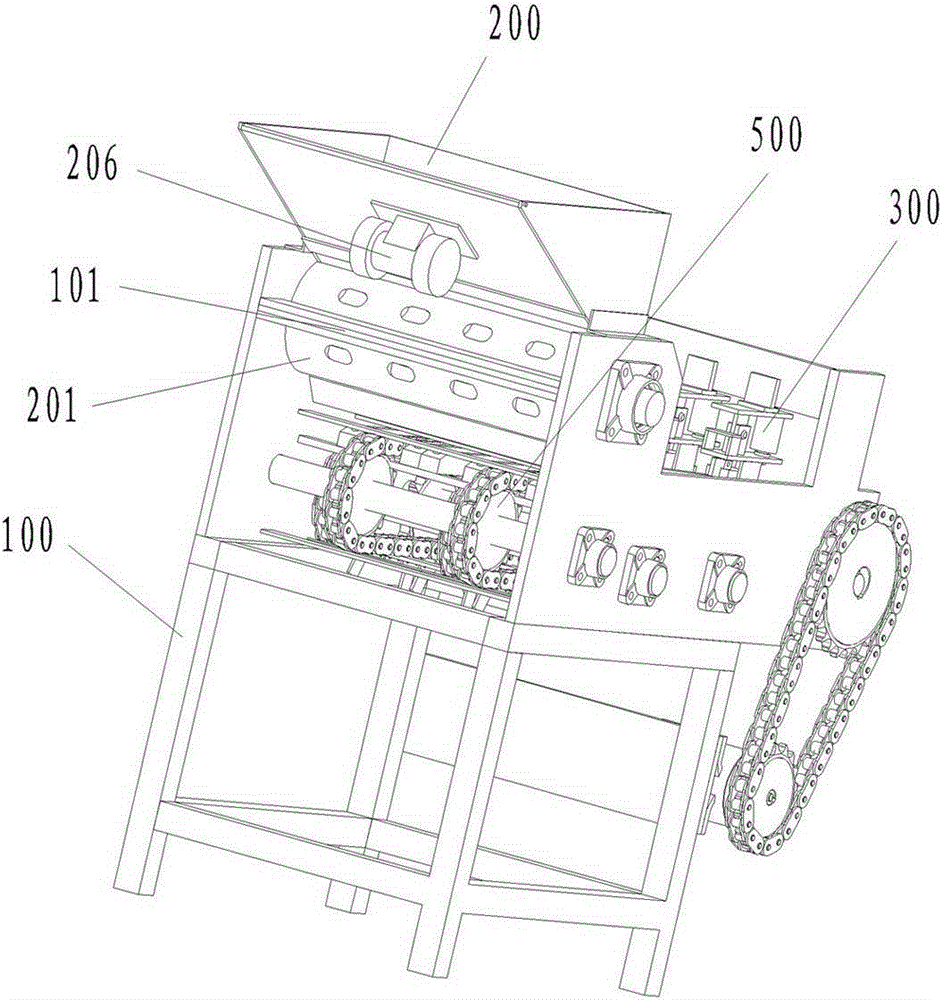

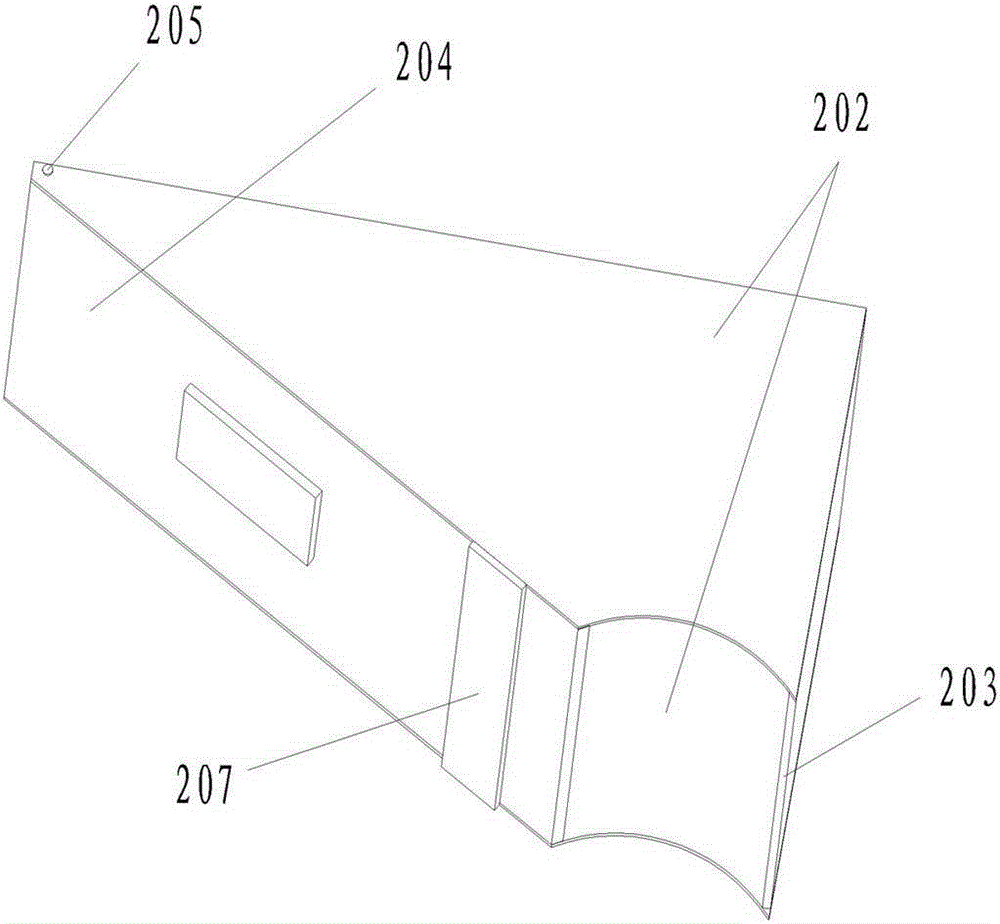

[0041] See attached figure 1 and 2 , the present invention provides a fully automatic cashew nut shelling machine, comprising a frame 100, a sorting and sorting mechanism 200 arranged on the frame 100, a cashew nut pushing mechanism 500, a shell breaking mechanism 300 and a sorting and sorting mechanism 200 and a shell breaking mechanism arranged on the frame 100 The key of the cashew nut conveying channel 400 between the mechanisms 300 is that the sorting and sorting mechanism 200 includes a feed hopper fixed on the frame 100, and the distribution material with the sub-storage tank 201-1 is arranged below the feed hopper outlet. The roller 201, the distribution roller 201 is positioned on the frame 100 and has a degree of freedom of rotation by means of the feeding drive. The material distribution roller 201 is directly positioned under the feed hopper, and the material distribution roller 201 is driven to rotate by the feed driving device, and the cashew nuts enter the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com