Tea leaf rolling method and processing technology of green tea and black tea using method

A processing technology and tea technology, applied in directions such as tea treatment before extraction, can solve problems such as unfavorable reaction and transformation of ingredients contained in tea leaves, insufficient and uniform rolling of tea leaves, weakening the degree of mechanical damage of tea leaves, etc., and simplify the tea making process. , Ensure cleanliness and food safety requirements, increase the effect of tea juice overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The green tea processing method of the present embodiment utilizing silica gel balls to enhance tea leaves rolling effect is carried out according to the following steps:

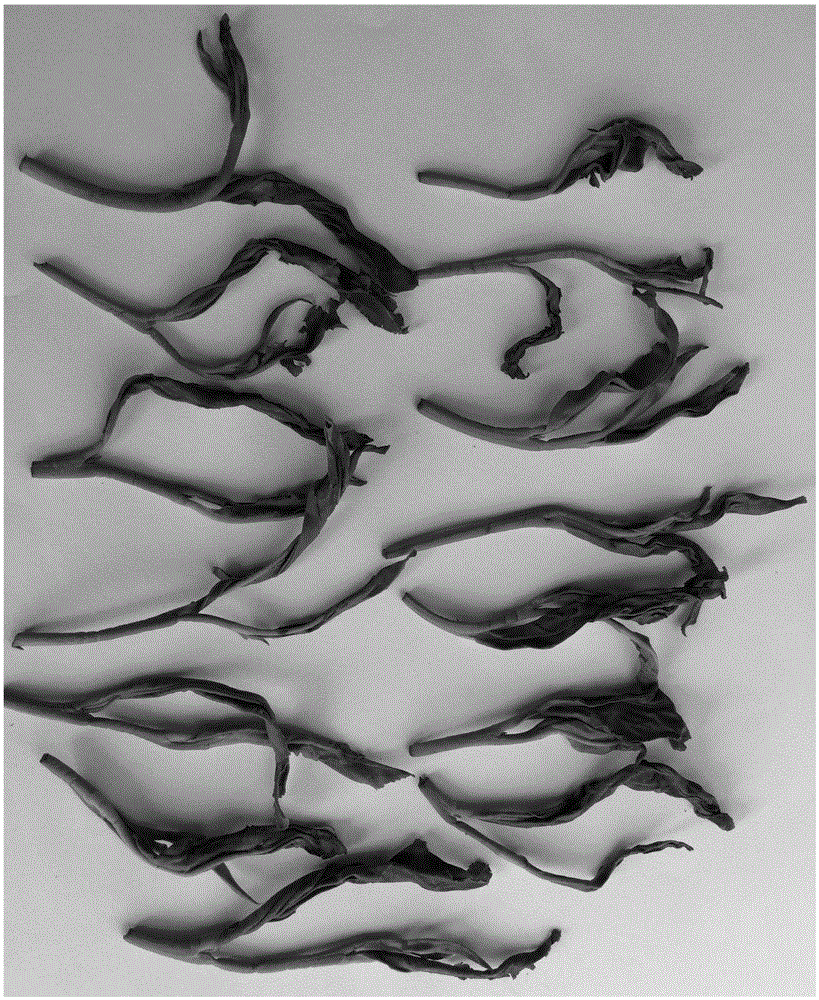

[0037] 1) Fresh leaves: select hand-picked fresh tea leaves in autumn, mainly with one bud and two or three leaves, and remove old leaves, red stems and non-tea foreign objects. Among the above-mentioned fresh tea leaves, one bud and two leaves account for 30% of the total amount, and one bud and three leaves account for 60% of the total amount. The fresh leaves are naturally spread indoors for 14 hours.

[0038] 2) Finishing: Roller finishing, the temperature of the inner wall of the cylinder is about 220°C, until the leaves are soft, slightly sticky, and the aroma is revealed.

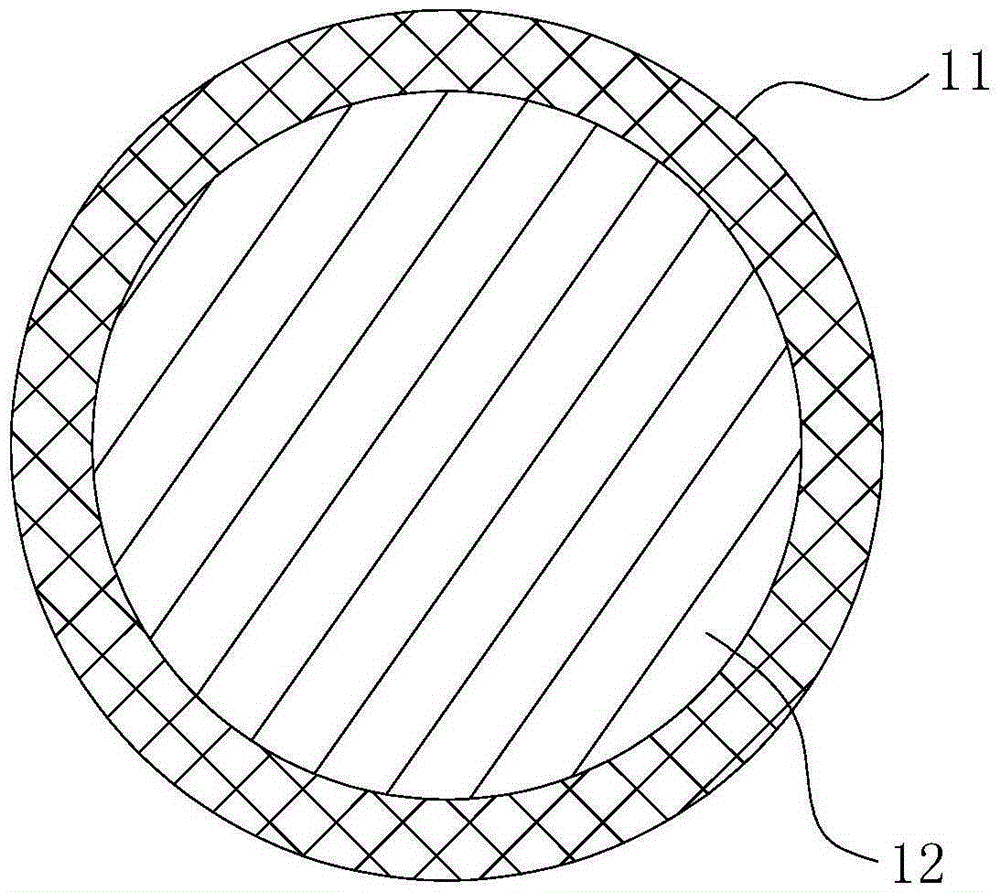

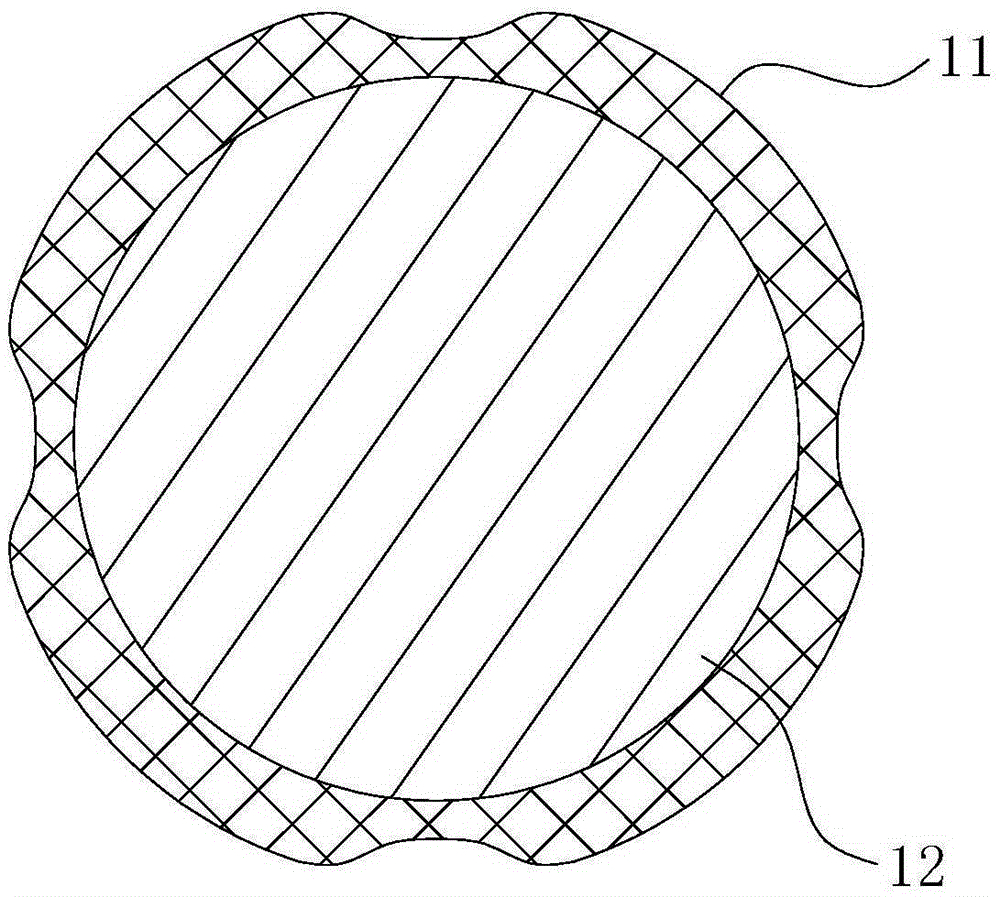

[0039] 3) Kneading: Use a 30-type kneading machine, and the amount of leaves thrown is about 5kg, that is, the kneading cylinder is naturally filled. Then add 20 food-grade silica gel balls with a diameter of 40 mm, about...

Embodiment 2

[0044] The method for processing black tea using silica gel balls to improve the rolling effect of tea leaves described in this embodiment is carried out in the following steps:

[0045] 1) Fresh leaves: select hand-picked fresh tea leaves in autumn, mainly with one bud and two or three leaves, and remove old leaves, red stems and non-tea foreign objects. Among the above-mentioned fresh tea leaves, one bud and two leaves account for 30% of the total amount, and one bud and three leaves account for 60% of the total amount. The fresh leaves are naturally spread indoors for 14 hours.

[0046] 2) Withering: Naturally wither indoors for 6 hours at a temperature of about 25°C. Outdoor sunlight (temperature about 30°C) withers until the leaf quality becomes soft, and the leaf color is dark green and loses luster. Lightly turn the leaves from time to time during this period to make the withering evenly; outdoor sun-dried for 10 minutes, and indoors for 40 minutes.

[0047] 3) Knead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com