Jute fiber kneading device

A kneading device and hemp fiber technology are applied in the field of hemp fiber processing device and hemp fiber kneading device, which can solve the problems of insignificant kneading effect, affecting the quality of hemp fiber, low production efficiency, etc., so as to improve stability and work efficiency. Efficiency, improvement in production rate, effect of improvement in production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

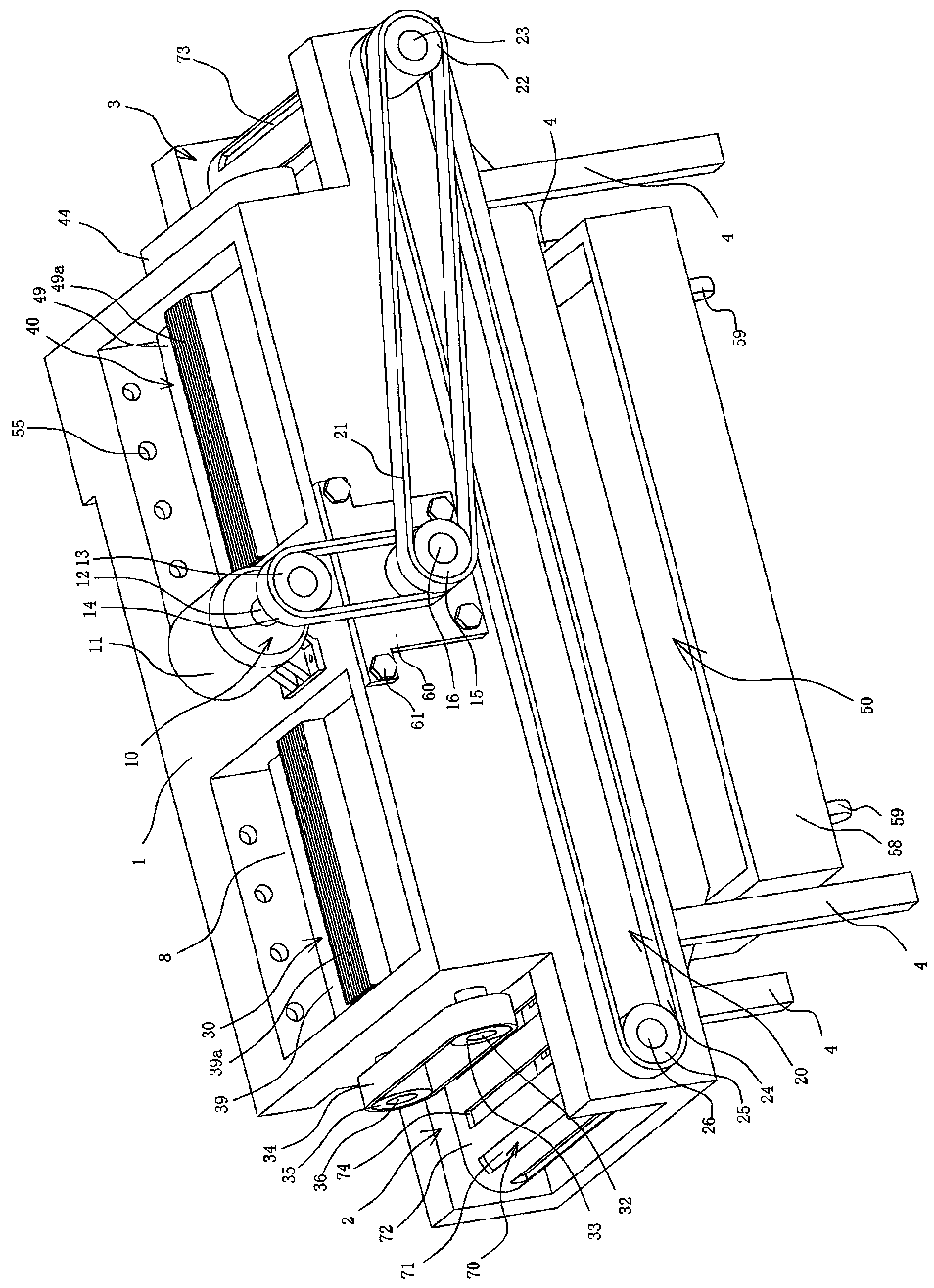

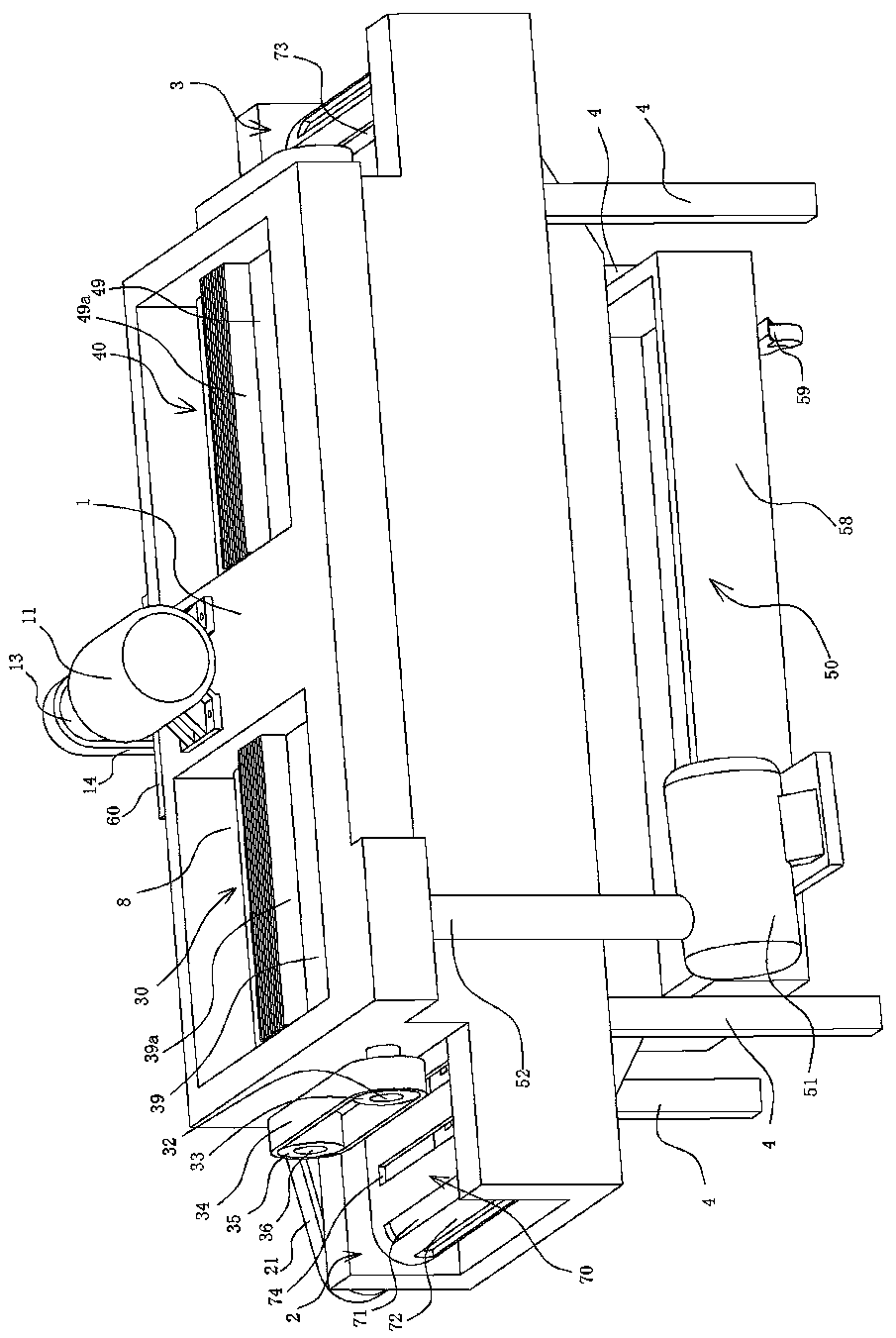

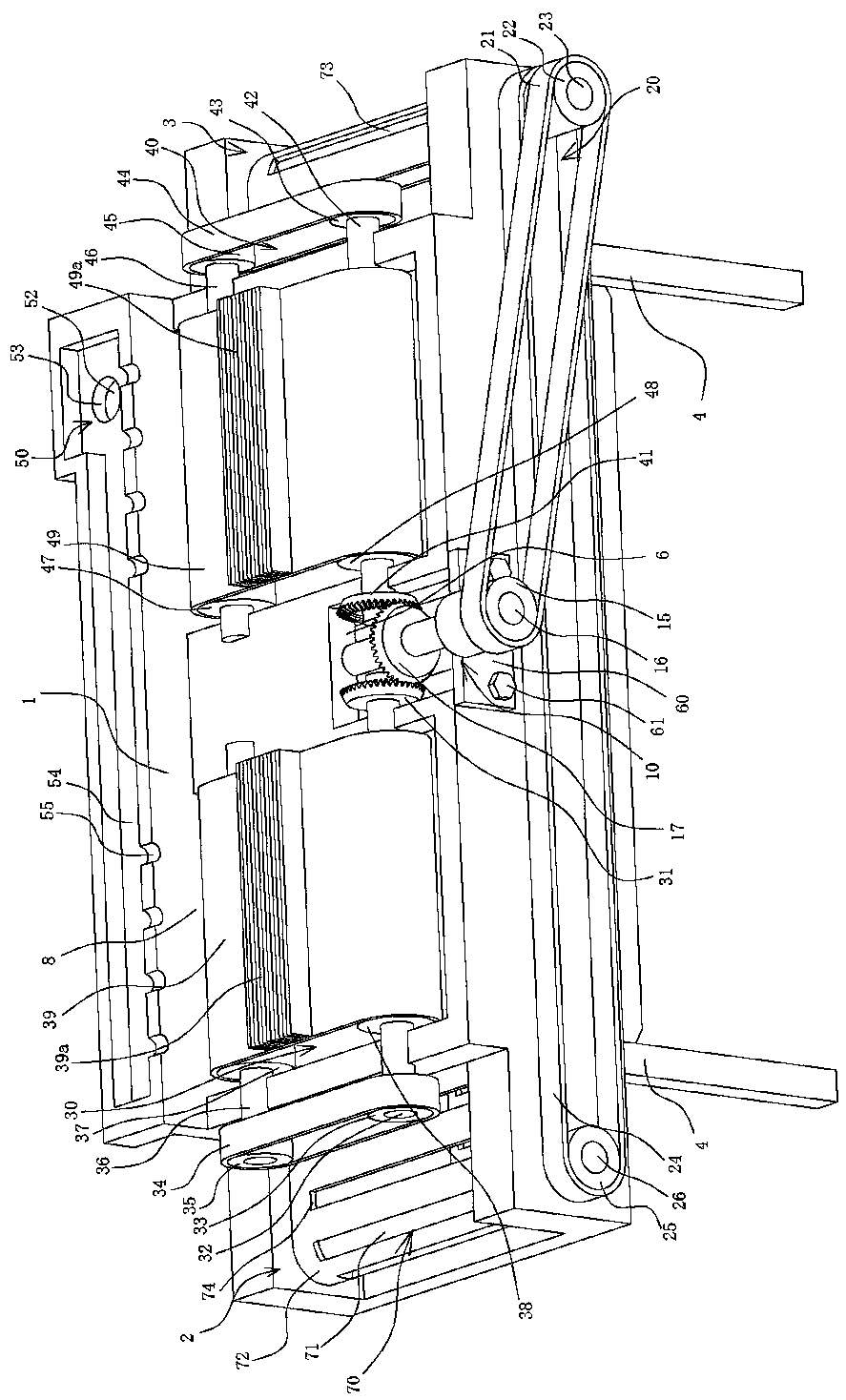

[0027] Such as figure 1 , figure 2 and image 3As shown, the hemp fiber kneading device of the present invention comprises a cabinet 1, the left side of the cabinet 1 is provided with a material inlet 2, the right side of the cabinet 1 is provided with a discharge port 3, the bottom of the cabinet 1 is provided with four legs 4, and the cabinet 1 is equipped with There is a working chamber 8, the upper end of the cabinet 1 is provided with a gear chamber 6, the top of the cabinet 1 is provided with a power mechanism 10, one end of the power mechanism 10 is provided with a transmission mechanism 20, and the other end of the transmission mechanism 20 is provided in the working chamber 8 and is equipped with a device for transporting hemp fiber. The transport mechanism 70, the other end of the power mechanism 10 is located in the gear cavity 6, the left side of the other end of the power mechanism 10 is provided with the first rubbing mechanism 30 for rubbing the hemp fiber, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com