Cleanser composition

A composition and detergent technology, which is applied in the direction of detergent composition, detergent composition fragrance, surface active detergent composition, etc., can solve the problems of damaging commodity value and hindering the aroma of fragrance, etc., and achieve the effect of improving the aroma of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

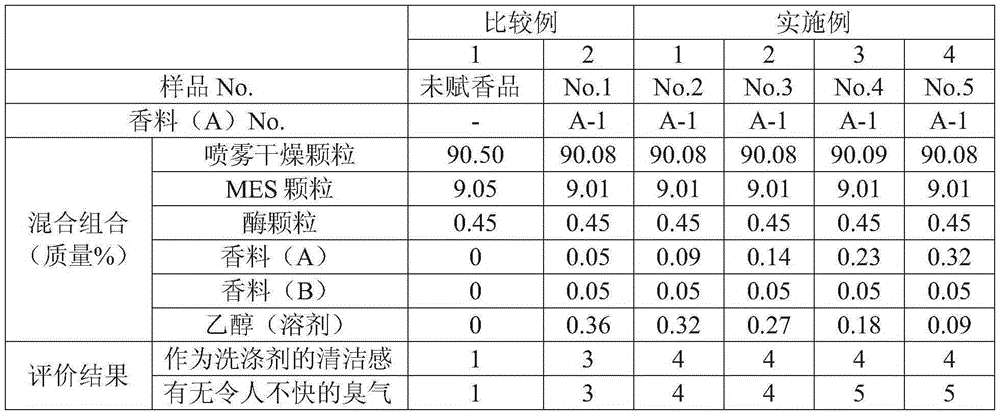

Embodiment 1~4、 comparative example 1~2

[0550] [Preparation of Basic Detergent]

[0551] The detergent raw materials described in Table 1 were mixed to prepare a detergent slurry having a solid content of 60% and a temperature of about 70°C. The addition order of each detergent raw material is not specifically limited. After adding all the detergent raw materials, the slurry was mixed at 70°C for about 2 hours, and dried at a hot air temperature of 260°C using a counter-flow spray drying tower until the moisture content reached about 5.5% by mass to obtain spray-dried granules. "Bal" in Table 1 represents the amount added to make the total amount 100% (balance amount).

[0552] 100 parts by mass of the obtained spray-dried granules, 10 parts by mass of MES granules, and 0.5 parts by mass of enzyme granules were powder-mixed to obtain a basic detergent (base granule group).

[0553] 【Table 1】

[0554] Detergent Raw Materials

Mixing amount in spray-dried granules (%)

LAS-Na

18

STPP ...

Embodiment 5~23、 comparative example 3~5

[0595] A fragrance (A), a fragrance (B), and ethanol were mixed so as to have the mixed compositions shown in Tables 6 to 10, and a fragrance composition was prepared. The substances shown in each of Tables 6 to 10 were used as the fragrance (A), and fragrances (B-1) to (B-3) were used as the fragrance (B). In addition, in Tables 6-9, fragrance (B-1) was used as fragrance (B).

[0596] The obtained fragrance composition was sprayed on the above-mentioned basic detergent to obtain a granular detergent composition.

[0597] Tables 6 to 10 show the mixed compositions (%) of spray-dried granules, MES granules, enzyme granules, fragrance (A), fragrance (B) and ethanol (solvent) in each example.

[0598] About the obtained granular detergent composition, the product aroma was evaluated by the procedure similar to the above. The results are recorded in Tables 6-10 together.

[0599] 【Table 6】

[0600]

[0601] 【Table 7】

[0602]

[0603] 【Table 8】

[0604]

[0605] 【Ta...

manufacture example 1~60

[0624] Fragrance components were mixed according to the mass ratio (unit: parts by mass) shown in each of Tables 12-14 to prepare fragrances 1-60 as fragrance (A).

[0625] Except having used any one of fragrances 1-60 instead of fragrance (A-1), it carried out similarly to Example 3, and prepared the granular detergent composition. The obtained granular detergent composition had a product aroma in which the clean feeling as a detergent could be fully sensed similarly to the granular detergent composition of Example 3, and almost no change in odor after storage was observed.

[0626]

[0627]

[0628]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com