Temperature detection device and heat treatment device

A technology for heat treatment equipment and testing equipment, which is applied in the direction of temperature measurement, thermometer, and heat measurement in household appliances, which can solve problems such as obstacles and adverse effects on structural integrity, and achieve the effects of low noise, stable temperature, and high antenna efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

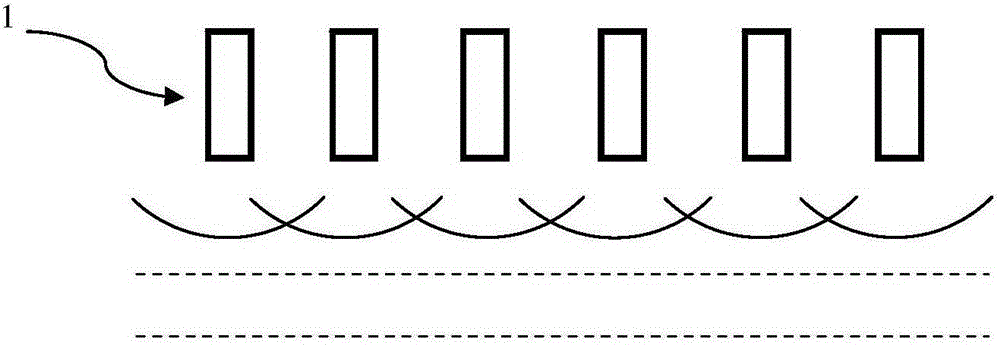

[0081] figure 1 A schematic illustration of an array antenna is shown. The array antenna consists of a plurality, here six, of antennas, which are connected electronically, preferably individually, and controlled such that their phase difference can be controlled. In the depicted case, all antennas comprise the same phase, ie the phase difference is zero. In this case, the signals from each antenna interfere constructively so that waves radiated from the antennas at a distance appear to be plane waves.

[0082] Alternatively, when using phased array antennas, the phases of the antennas can be adjusted so that their signals interfere in such a way as to create a highly directional antenna pattern. Thus, the directivity 200 of the phased array antenna can be controlled, allowing focusing on a very small area, for example on the scale of a few square meters.

[0083] figure 2 A schematic top view of a heat treatment device 4 according to an exemplary embodiment of the inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com