Membrane electrode assembly of fuel cell

A fuel cell membrane and electrode technology, which is applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the electrochemical performance affecting the reaction activity of fuel cell membrane electrodes, restrict the uniform diffusion of reaction gas in the gas diffusion layer, and the uneven distribution of carbon fibers, etc. problem, to achieve the effect of improving the ability of uniform diffusion of reaction gas, improving the ability of conducting electrons, and uniform distribution of carbon fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

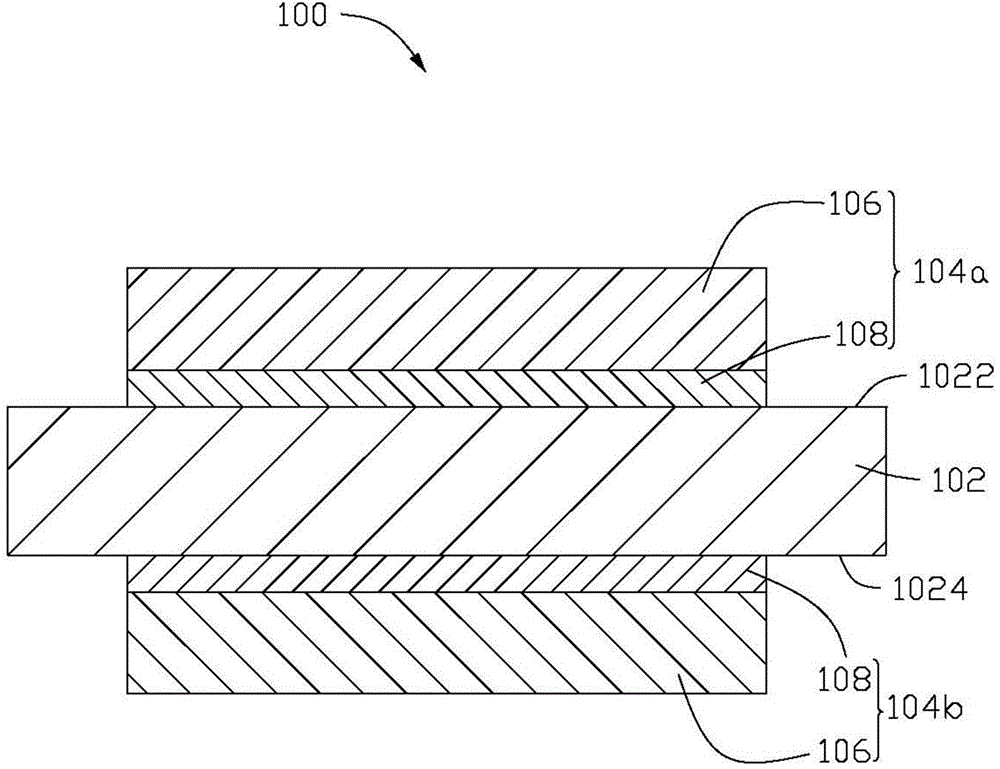

[0032] The first embodiment of the present invention further provides a method for preparing the fuel cell membrane electrode 100, which specifically includes the following steps:

[0033] S10, preparing a carbon fiber membrane 50 as the gas diffusion layer 106;

[0034] S11, forming a catalytic layer 108 on a surface of the gas diffusion layer 106, thereby obtaining the first electrode 104a and the second electrode 104b;

[0035] S12 , providing a proton exchange membrane 102 , and disposing the first electrode 104 a and the second electrode 104 b on two opposite surfaces of the proton exchange membrane 102 , so as to obtain a fuel cell membrane electrode 100 .

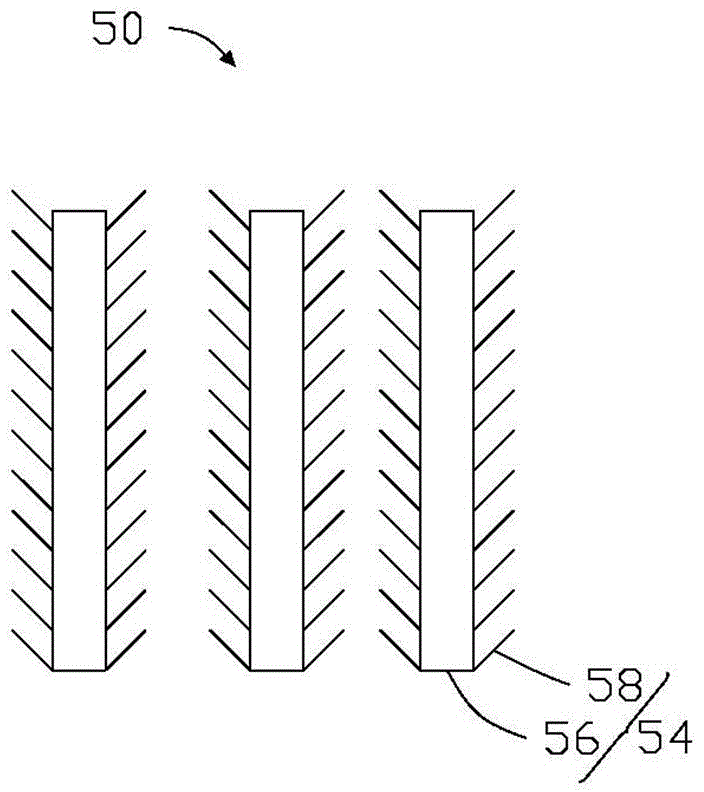

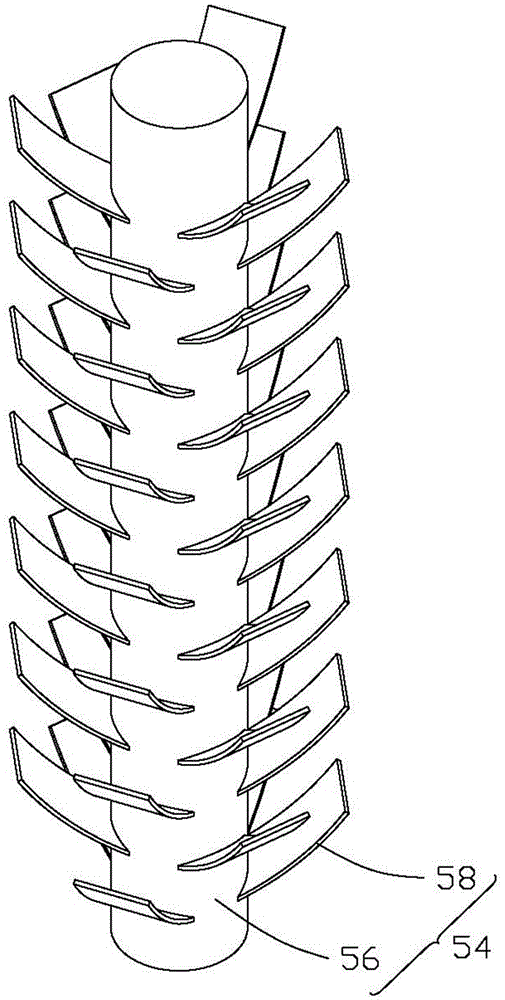

[0036] See Figure 4 , in step S10, the preparation method of the carbon fiber membrane 50 specifically includes the following steps:

[0037] S101, providing a carbon nanotube array 10;

[0038] S102, pulling from the carbon nanotube array 10 to obtain a carbon nanotube film 20, passing the carbon nanotube film 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com