Auxiliary operation tool for link stick

A technology of auxiliary operation and crimping rod, which is applied to switches, high-voltage air circuit breakers, and electrical components operated by live operating levers, which can solve the problem of time-consuming and labor-intensive switching operation of 500KW substations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in more detail below in conjunction with the accompanying drawings.

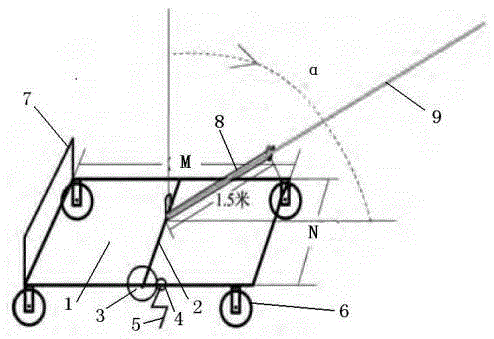

[0015] Such as figure 1 As shown, an auxiliary operation tool for a wand of the present invention includes a base frame 1, a rotating shaft 2 is installed on the base frame 1, a mechanical arm pipe 8 is fixedly connected to the rotating shaft 2, and the rotating shaft 2 One end is fixedly connected with a first gear 3, the first gear 3 meshes with the second gear 4, a rocker 5 is installed on the second gear 4, and a universal roller 6 is installed on the bottom frame 1. The underframe 1 is also fixedly connected with a handrail bar 7, and the inside of the mechanical arm tube 8 is provided with a protective layer. The shape of the underframe 1 is rectangular. The length M of the underframe 1 is 2 meters, and the width N is 1.2 meters. m, the swing angle range of the mechanical arm tube 8 is 0°——90°

[0016] The working process of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com